Double Plate Check Valve

Double plate check valve is also known as dual plate check valve, dual plate non return Valve or dual door check valve, and its valve body and valve plate are cast from high-quality stainless steel to ensure the service life of your application system.

If you are looking for a compact, durable and high-performance solution for pipe backflow, the TOT Valve is designed to exceed your expectations. With anti-slam performance, excellent corrosion resistance and low pressure drop, this double plate check valve is trusted by many industrial and commercial systems around the world.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

Our dual plate check valve fully complies with API 594 standards, and engineered with a spring-loaded, double-door design that closes automatically to stop reverse flow. This dual disc check valve uses two semi-circular discs attached to a central hinge shaft, balanced with independent torsion springs for rapid closure.

Designed in both wafer type and lug type options, our dual plate check valve wafer type configuration fits easily between flanges making it ideal for compact piping systems or system upgrades. The valve’s streamlined flow path ensures minimal pressure loss and high flow efficiency.

Get a quote now and let us help you find the right double plate check valve for your application in the shortest possible time.

Double Plate Check Valve Features

- Dual spring-loaded plates for fast, balanced closure

- Non-slam design to minimize water hammer and pressure surges

- Wafer and lug types available to fit multiple pipeline layouts

- Bi-directional sealing ensures tight shutoff in both flow directions

- Wide material range including ductile iron, stainless steel, and exotic alloys

- Supports horizontal and vertical installations

- Retainerless design available to eliminate body leakage risks

- Simplifies installation in tight spaces

- Market competitive price

Main Technical Parameters & Performance

| Specification | Value |

| Size | DN50–DN1000 (2″–40″) |

| Face to Face | API609, BS5155, DIN3202, ISO5752 |

| Pressure Ratings | PN10 / PN16 / ANSI 150 / JIS 10K |

| Standards Compliance | API 594, EN 558, ISO 5752 |

| Working Temperature | -10°C to 180°C (14°F to 356°F), depending on materials |

| Flow Direction | Uni-directional, bi-directional sealing optional |

| Seat Options | Soft seat (EPDM, NBR, PTFE) or metal-to-metal |

| Cracking Pressure | ≤ 0.2 bar |

| Application | HVAC, Water Supply & Sewage, Food & Beverage, Chemical/Petrochemical Processing, Power and Utilities, Paper and Pulp, Ship Building |

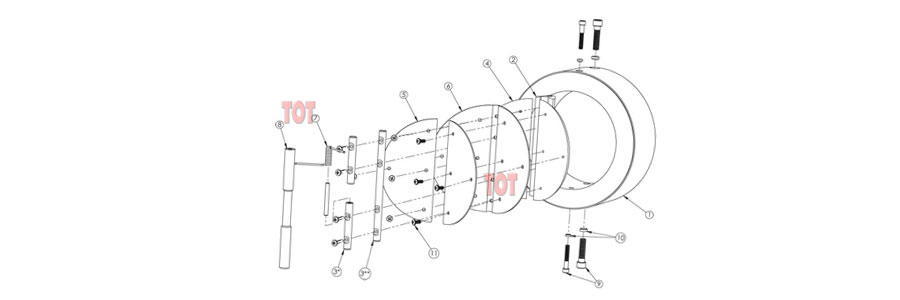

Main Components and Materials

| Part | Materials |

|---|---|

| Body | CF8, CF8M, WCB, or Custom Alloy Steel |

| Plate | CF8, CF8M |

| Spring | Stainless Steel |

| Hinge Pin | Stainless Steel |

| Plug | Carbon Steel |

| Body Bearing | PTFE |

| Spring Bearing | PTFE |

| Stop Pin | Stainless Steel |

| Eye Bolt | Carbon Steel |

| Body Seat | EPDM, NBR, Viton, Neoprene |

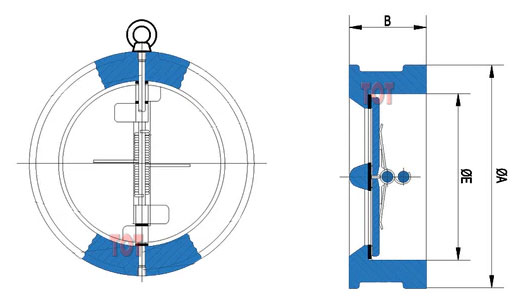

Double Plate Check Valve Dimensions

TOT valve can provide you with various sizes of double plate check valve. We have listed some double plate check valve for 2″-32″ for your reference.

If you don’t have the double plate check valve you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | B | E | PN10/16 | 150 LB | 10K | |

|---|---|---|---|---|---|---|

| DN | In | |||||

| 2″ | 50 | 43 | 66 | 107 | 102 | 101 |

| 2-1/2″ | 65 | 46 | 86 | 127 | 121 | 121 |

| 3″ | 80 | 64 | 95 | 142 | 133 | 131 |

| 4″ | 100 | 64 | 118 | 162 | 171 | 156 |

| 5″ | 125 | 70 | 146 | 192 | 193 | 187 |

| 6″ | 150 | 76 | 174 | 218 | 219 | 217 |

| 8″ | 200 | 89 | 225 | 273 | 276 | 267 |

| 10″ | 250 | 114 | 266 | 328 | 336 | 330 |

| 12″ | 300 | 114 | 311 | 378/382 | 406 | 375 |

| 14″ | 350 | 127 | 361 | 438/442 | 448 | 420 |

| 16″ | 400 | 140 | 411 | 488/495 | 511 | 483 |

| 18″ | 450 | 152 | 451 | 538/555 | 546 | 538 |

| 20″ | 500 | 152 | 506 | 592/617 | 603 | 593 |

| 24″ | 600 | 178 | 625 | 695/734 | 714 | 697 |

| 28″ | 700 | 229 | 721 | 809 | 828 | 807 |

| 32″ | 800 | 241 | 826 | 916 | 936 | 917 |

Applications That Require High Reliability

This dual plate check valve is your trusted choice for industries that cannot afford failure:

- Water supply and wastewater treatment

- HVAC systems, fire protection, and chilled water circuits

- Chemical processing and industrial fluid handling

- Power generation, turbines, and condensate systems

- Oil, gas, and petrochemical systems

- Marine, mining, and pulp & paper pipelines

As a leading dual plate check valve manufacturer, we offer custom-engineered solutions for demanding operating conditions.

FAQ

How does a double plate check valve work?

A double plate check valve, also known as a dual plate check valve or dual door check valve, uses two spring-loaded half-discs hinged in the center. When fluid flows in the correct direction, the plates open. If flow reverses or stops, the spring mechanism quickly closes the plates to prevent backflow.

Where are dual plate check valves used?

These valves are commonly used in water supply systems, HVAC, chemical processing, oil & gas, power generation, and other industrial applications where compact design and non-slam performance are required.

How do I choose the right material for a dual plate check valve?

Material selection depends on media type, temperature, and pressure. Common materials include stainless steel, carbon steel, ductile iron, and bronze. For corrosive or aggressive fluids, opt for stainless steel or special alloys.

Can a dual plate check valve be installed vertically?

Yes. Dual plate check valves can be installed either horizontally or vertically (flow upward). Ensure the valve is installed according to the flow direction arrow and has enough space for the plates to operate freely.

What is a retainerless dual plate check valve?

A retainerless design eliminates body-through bolts, reducing the risk of external leakage. It’s ideal for high-purity, hazardous, or corrosive applications where sealing integrity is critical.

How should I maintain a double plate check valve?

These valves require minimal maintenance. Periodically inspect for wear, debris, or corrosion on the plates, shafts, and springs. For critical systems, conduct regular functional testing.

What are the advantages of a dual plate check valve over a swing check valve?

Dual plate check valves are more compact, lighter, and close faster, which helps reduce water hammer. They also offer lower pressure drop and better performance in vertical installations.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.