A pressure compensated flow control valve is a specialized hydraulic component designed to maintain a constant flow rate regardless of pressure fluctuations in a fluid system. These valves are critical in applications where precise control over actuator speed or process flow is required—even when load conditions change. In this guide, we explain how pressure compensated flow control valves work, their schematic symbols, and where they are commonly used.

Table of Contents

ToggleWhat Is a Pressure Compensated Flow Control Valve?

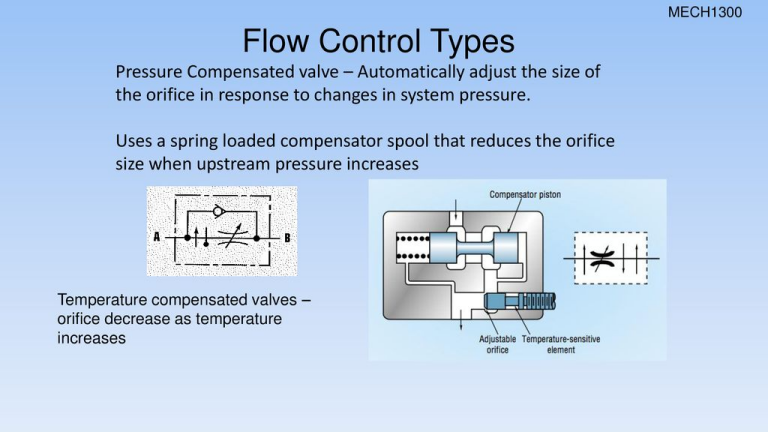

Unlike standard flow control valves that regulate flow based solely on an adjustable orifice, a pressure compensated flow control valve incorporates a pressure-sensing mechanism. This allows the valve to automatically adjust internal restrictions to compensate for upstream or downstream pressure variations.

Key Functions:

- Maintain steady flow despite load changes

- Improve actuator speed consistency

- Prevent system inefficiencies due to pressure spikes

How It Works

A typical pressure compensated flow control valve consists of:

- An adjustable orifice

- A pressure compensator spool

- A spring

When pressure increases upstream, the compensator spool reacts by adjusting the orifice size to maintain the set flow rate. This ensures consistent performance even as system pressures fluctuate.

Pressure Compensated Flow Control Valve Symbol

In hydraulic schematics (ISO 1219 or ANSI standards), the pressure compensated flow control valve symbol includes:

- A flow restriction symbol (◄)

- An arrow indicating adjustability

- Pressure compensation often shown with a spring or a pilot line

Example:

┌─────┐

| ◄↔ |

└─────┘Sometimes, it may be annotated with labels such as “PCFC” or simply included in hydraulic circuit diagrams next to actuators.

Applications of Pressure Compensated Flow Control Valves

These valves are used wherever precise flow regulation is necessary under variable pressure conditions. Common applications include:

- Hydraulic systems with varying loads

- Industrial automation equipment

- Construction machinery (e.g., excavators, loaders)

- Injection molding machines

- Agricultural equipment (tractors, sprayers)

- CNC and machine tools

Advantages Over Non-Compensated Valves

- Stable actuator speed

- Reduced energy waste

- Longer equipment life due to controlled flow

- Improved process repeatability

Related Terms

- Flow control valve

- Hydraulic flow control valve

- Adjustable flow valve

- Load-sensing valve

- Pressure control valve

These may overlap in function or terminology, but pressure compensated flow control valve specifically implies flow rate stabilization in dynamic pressure environments.

Conclusion

A pressure compensated flow control valve is essential for maintaining performance and efficiency in modern hydraulic and fluid power systems. Whether in mobile equipment, factory automation, or high-precision machines, these valves help ensure predictable and consistent flow behavior.

Looking for the right pressure compensated valve for your system? Contact our technical team for expert assistance and product recommendations.