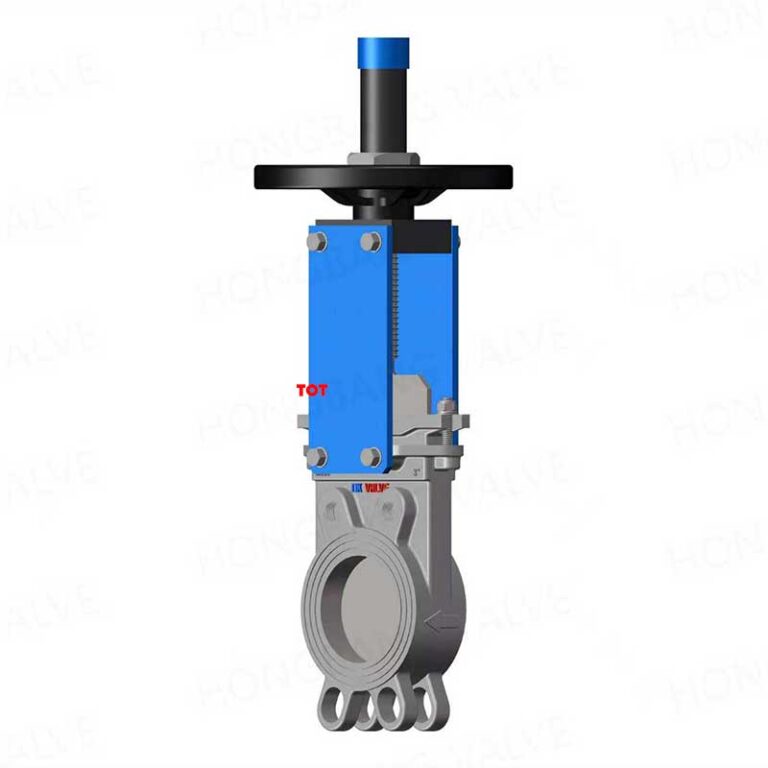

DN50 knife gate valve (2 inch)

The DN50 knife gate valve delivers exceptional performance in compact 2-inch pipeline systems. Engineered for precision applications including sampling lines, pilot systems, and process control, this valve combines the superior cutting action of larger knife gates with space-efficient design perfect for instrumentation and critical small-bore applications.

Key Applications: Sampling Systems • Chemical Processing • Water Treatment • HVAC • Laboratory Systems • Instrumentation

Why Choose DN50 Knife Gate Valve?

✓ Compact Excellence

- Space-efficient 2-inch design for tight installations

- Full bore flow path maintains maximum capacity

- Lightweight construction reduces pipeline stress

✓ Precision Engineering

- CNC-machined components for smooth operation

- Bubble-tight sealing with zero leakage performance

- Superior cutting action through settled solids and fibrous materials

✓ Versatile Configuration

- Wafer Type: 48mm face-to-face, ideal for retrofits

- Lug Type: Independent mounting, perfect for dead-end service

- Flanged Type: 65mm face-to-face, maximum strength for high pressure

✓ Material Excellence

- Stainless steel construction (304/316/316L)

- Multiple seat options: EPDM, PTFE, Metal seated

- Corrosion-resistant components for aggressive media

Technical Specifications

| Parameter | Specification |

|---|---|

| Nominal Size | DN50 (2 inches) |

| Pressure Rating | PN6/10/16/25, ANSI 150/300 |

| Working Pressure | Up to 16 Bar (232 PSI) |

| Temperature Range | -29°C to +425°C |

| Cv Value | 110 (full open) |

| Body Materials | WCB, CF8, CF8M, CF3M |

| Standards | MSS SP-81, API 6D, ASME B16.5 |

| End Connections | RF, FF, RTJ |

Configuration Options & Dimensions

Wafer Type DN50

- Face-to-Face: 48mm

- Weight: 8-12 kg

- Best For: Retrofit applications, space-saving

Lug Type DN50

- Face-to-Face: 48mm

- Weight: 10-15 kg

- Best For: Dead-end service, easy maintenance

Flanged Type DN50

- Face-to-Face: 65mm

- Weight: 15-25 kg

- Best For: High pressure, critical applications

Performance Data

| Performance Parameter | Value |

|---|---|

| Maximum Flow Rate (Water) | 180 m³/h |

| Pressure Drop (Full Open) | 0.1 Bar |

| Operating Torque | 25-45 Nm |

| Closing Time (Manual) | 15-20 seconds |

| Cycle Life | 10,000+ cycles |

| Leakage Rate | Zero (Class VI) |

Application Solutions

Process Control Systems

- Sample line isolation valves

- Pilot system controls

- Bypass line regulation

- Emergency shutdown systems

Water & Wastewater Treatment

- Chemical dosing systems

- Sampling point isolation

- Small bore transfer lines

- Instrumentation isolation

Chemical Processing

- Reactor sampling lines

- Catalyst transfer systems

- Laboratory connections

- Process monitoring lines

HVAC & Building Services

- Heating system isolation

- Cooling water circuits

- Equipment isolation

- Utility line control

Actuation Options

Manual Operation

- Standard handwheel

- Extended stem for buried service

- Gear drive for high torque applications

Automated Operation

- Pneumatic: Single/double acting with position feedback

- Electric: Multi-turn actuators with local/remote control

- Smart Features: Position indicators, limit switches, SCADA integration

Material Options

Body Materials

- WCB: Carbon steel for general service

- CF8: 304 stainless steel for corrosive environments

- CF8M: 316 stainless steel for enhanced corrosion resistance

Seat Options

- EPDM: General service, water applications (-20°C to +120°C)

- PTFE: Universal chemical resistance (-200°C to +260°C)

- Metal Seated: Stellite overlay for high temperature/abrasive service

Special Materials

- Duplex 2205: For severe corrosive environments

- Hastelloy: For extreme chemical compatibility

- Custom alloys available upon request

Quality Assurance

Testing Standards

- Hydrostatic shell test at 1.5× working pressure

- Seat leakage test per MSS SP-81 Class VI

- Operating torque verification

- Material certification with full traceability

Certifications

- ISO 9001 Quality Management

- PED (Pressure Equipment Directive) compliance

- CE marking for European markets

- Custom certifications available

Installation & Maintenance

Installation Requirements

- Minimum straight pipe: 5D upstream, 2D downstream

- Support valve independently for flanged types

- Allow clearance for stem extension during operation

Maintenance Benefits

- Field-replaceable seats and packing

- No special tools required for service

- Accessible components reduce downtime

- Comprehensive spare parts support

Recommended Spare Parts

- Seat and gasket kit

- Packing set

- Bolting kit

- Operating manual and drawings

Competitive Advantages

🔧 Precision Engineering – CNC machined components ensure consistent performance

📏 Compact Design – Minimal space requirements for installation

🔄 Versatile Mounting – Multiple body configurations for any application

⚡ Easy Service – Field-replaceable components reduce downtime

🌍 Global Standards – Compliance with international design standards

📦 Fast Delivery – Standard DN50 configurations available from stock

Get Your DN50 Solution Today

Ready to optimize your 2-inch pipeline systems? Contact our technical team for expert consultation and competitive quotation on DN50 knife gate valves tailored to your specific requirements.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.