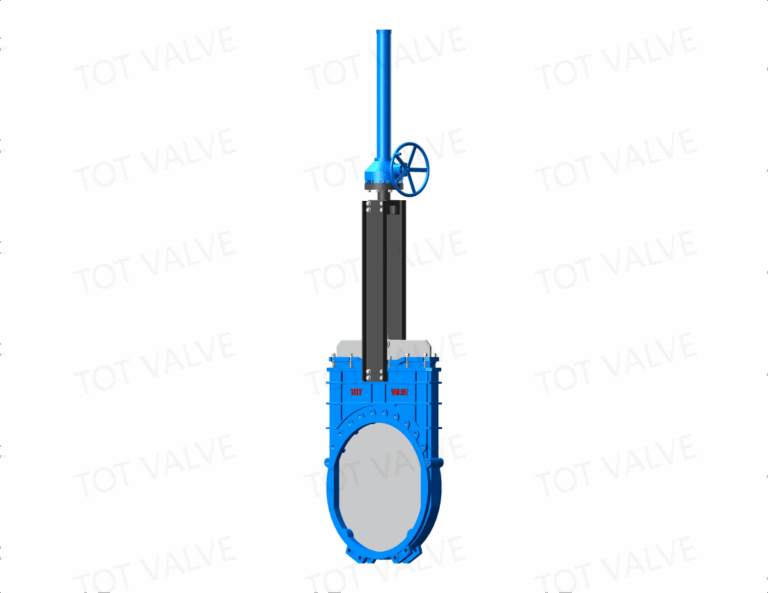

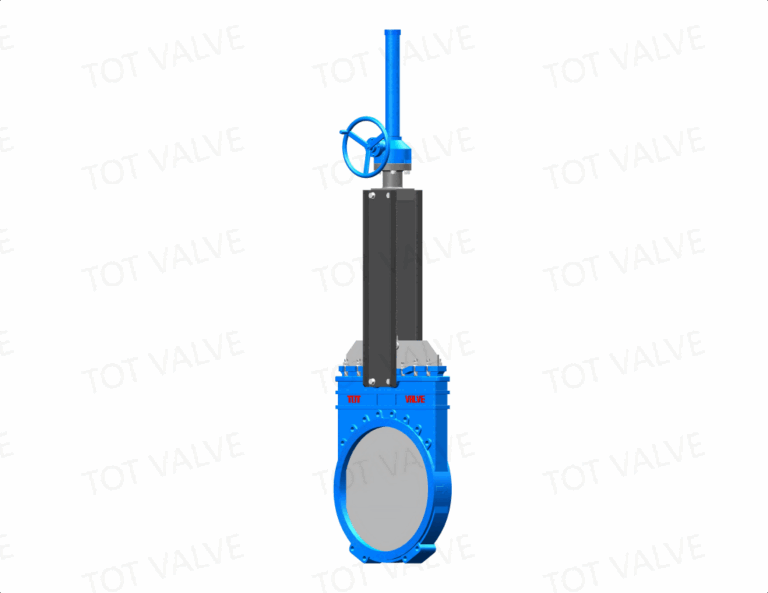

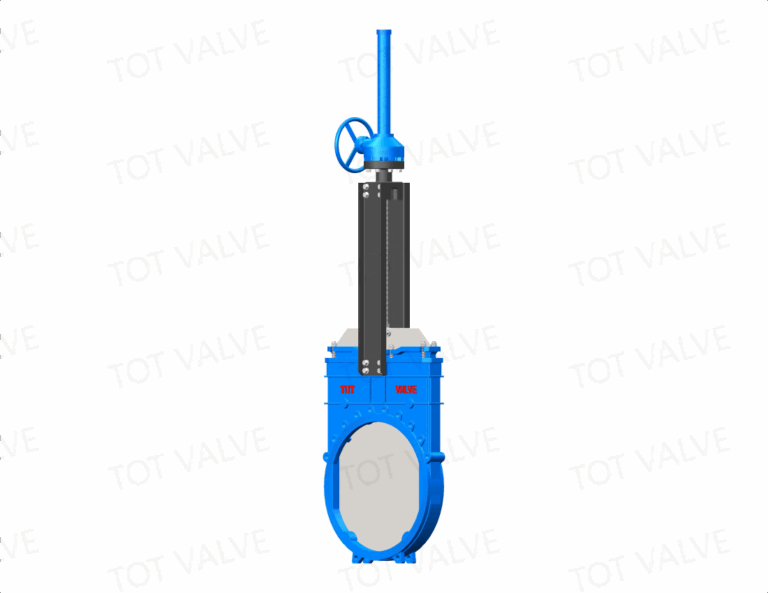

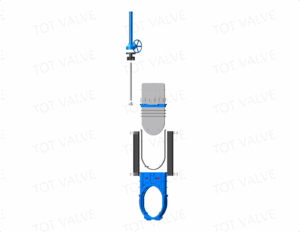

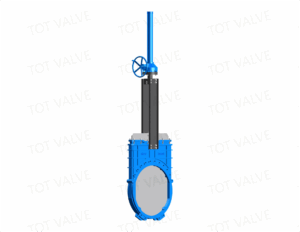

DN1000 Bidirectional Knife Gate Valve

When your ultra-large diameter pipeline requires reliable bidirectional sealing and optimal flow control, the DN1000 bidirectional knife gate valve delivers exceptional performance and operational flexibility. This robust DN1000 bidirectional knife gate valve is engineered for large-scale applications demanding reliable shutoff in both flow directions — whether you’re managing water treatment facilities, industrial cooling systems, or process pipelines where flow reversal and tight sealing are essential. The advanced bidirectional sealing design ensures positive shutoff regardless of flow direction, while maintaining the superior cutting action of our proven large-diameter knife gate technology. With dual sealing capability and heavy-duty construction, it provides dependable service in demanding large-pipeline applications where operational versatility is critical.

Ready to achieve reliable bidirectional control in your DN1000 pipeline systems? Contact us today for a DN1000 bidirectional solution engineered for your specific flow requirements. Let TOT Valve secure your operations with proven large-valve reliability.

The TOT Valve You Can Depend On – DN1000 Bidirectional Excellence When Ultra-Large-Scale Versatility Matters

When your ultra-large-diameter process requires reliable sealing regardless of flow direction, operational flexibility, or emergency isolation capability from either side, you need the superior versatility of our DN1000 bidirectional knife gate valve. With advanced dual-direction sealing technology, this large knife gate valve provides reliable shutoff from both directions, exceptional flow characteristics, and outstanding durability — all while maintaining the reliable cutting action that makes knife gates ideal for challenging ultra-large-pipeline media.

The bidirectional design provides flexible flow control and consistent sealing performance throughout the valve’s service life, making it the preferred choice for ultra-large-scale water treatment, industrial process, and infrastructure applications.

Why DN1000 Bidirectional Knife Gate Valve Works for You?

DN1000 bidirectional knife gate valve features

- Dual-direction sealing provides reliable shutoff regardless of upstream/downstream pressure configuration

- Optimized DN1000 design with specialized engineering for 1000mm ultra-large-diameter applications

- High flow capacity handles up to 27,000 m³/h with minimal pressure loss

- Flow reversibility accommodates changing process directions without valve repositioning

- Symmetrical seat configuration ensures equal sealing performance in both flow directions

- Corrosion-resistant construction with stainless steel components for extended service life

- Knife-edge gate efficiently cuts through large debris, settled materials, and fibrous media

- Multiple actuation compatibility supports manual, pneumatic, electric, and hydraulic operation

- Pressure equalization design prevents pressure lock and ensures smooth ultra-large-valve operation

- Heavy-duty stem assembly withstands high thrust loads typical in DN1000 applications

- Emergency isolation capability for rapid pipeline shutoff from either direction

DN1000 Bidirectional Knife Gate Valve Main Technical Specifications

Ultra-Large-Diameter Performance, Bidirectional Technology, DN1000 Knife Gate Valve

| Specification | Details |

|---|---|

| Valve Size | DN1000 (NPS 40″) |

| Design Standard | MSS SP-81, AWWA C515, EN 593 |

| Pressure Ratings | PN6, PN10, PN16 |

| Maximum Flow Rate | 27,000 m³/h at 9.5 m/s velocity |

| Parameter | PN6 | PN10 | PN16 |

|---|---|---|---|

| Working Pressure | 6 Bar | 10 Bar | 16 Bar |

| Test Pressure | 9 Bar | 15 Bar | 24 Bar |

| Max Velocity | 2.0 m/s | 2.5 m/s | 3.0 m/s |

| Standard | Face-to-Face | Flange Type | Weight Range |

|---|---|---|---|

| MSS SP-81 | 115mm | ANSI B16.5 | 850-1500 kg |

| AWWA C515 | 127mm | AWWA C207 | 920-1620 kg |

| EN 593 | 115mm | EN 1092-2 | 880-1550 kg |

DN1000 Dimensional Specifications & Materials

| Component | Material | Dimension | Standard |

|---|---|---|---|

| Body | WCB/CF8M | Ø1000mm bore | ASTM A216 |

| Gate | 316L SS | 12mm thickness | ASTM A240 |

| Flange | WCB/CF8M | Per rating | ASME B16.5 |

| Stem | 316L SS | Ø80-100mm | ASTM A276 |

Bidirectional Sealing Performance

| Flow Direction | Sealing Class | Test Pressure | Leakage Rate |

|---|---|---|---|

| Upstream Seal | Class VI | 6-16 Bar | ≤0.1 ml/min/inch |

| Downstream Seal | Class VI | 6-16 Bar | ≤0.1 ml/min/inch |

| Bidirectional | Class VI | 6-16 Bar | ≤0.1 ml/min/inch |

Actuation Options for DN1000 Service

Manual Operation:

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Gear Ratio | 50:1 | – | Recommended |

| Operating Torque | 8,500 | Nm | At rated pressure |

| Handwheel Size | 750 | mm | Standard |

| Operating Force | 1,200 | N | Rim force |

Pneumatic Operation:

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Actuator Size | Ø500 | mm | Cylinder diameter |

| Air Pressure | 6-7 | Bar | Supply requirement |

| Operating Time | 90-180 | sec | Variable speed |

| Air Consumption | 280 | L/cycle | Per operation |

Electric Operation:

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Motor Power | 7.5-11 | kW | Variable speed |

| Operating Time | 240-480 | sec | Programmable |

| Control Accuracy | ±0.2 | % | Position feedback |

| Power Consumption | 25-35 | A | At 380VAC |

Hydraulic Operation:

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Cylinder Force | 600-1000 | kN | Output force |

| System Pressure | 140-210 | Bar | Operating range |

| Cycle Time | 60-240 | sec | Variable control |

| Flow Requirement | 150-250 | L/min | Hydraulic flow |

Advanced Bidirectional Technology

Symmetrical Design: Equal performance characteristics in both flow directions

Pressure Balance: Gate design minimizes differential pressure effects on operation

Flow Optimization: Streamlined internal geometry maximizes flow coefficient

Debris Management: Large gate opening accommodates substantial debris passage

Thermal Compensation: Design accounts for thermal expansion in ultra-large-diameter service

Vibration Resistance: Heavy-duty construction minimizes flow-induced vibration

Application-Specific Configurations

Water Treatment Plants:

| Feature | Specification | Benefit | Standard |

|---|---|---|---|

| Seat Material | EPDM | Potable water safe | NSF-61 |

| Body Material | CF8M | Corrosion resistance | ASTM A351 |

| Actuation | Electric | Remote control | IEC 60034 |

| Coating | Fusion Bond Epoxy | Long-term protection | AWWA C550 |

Industrial Process:

| Feature | Specification | Benefit | Standard |

|---|---|---|---|

| Seat Material | Viton/PTFE | Chemical resistance | ASTM D2000 |

| Body Material | Duplex 2205 | High strength | ASTM A890 |

| Actuation | Pneumatic | Fast response | ISO 5599 |

| Design | Fire-safe | Emergency safety | API 607 |

Performance Testing & Validation

Flow Testing:

| Test Type | Standard | Parameter | Acceptance |

|---|---|---|---|

| Cv Verification | ISA-75 | Flow coefficient | ±5% of calculated |

| Pressure Loss | ISO 5167 | ΔP measurement | ≤0.4 Bar @ rated flow |

| Cavitation | IEC 60534 | Sigma limits | Per application |

Sealing Testing:

| Direction | Standard | Pressure | Leakage Limit |

|---|---|---|---|

| Forward | MSS SP-81 | 1.1 × rated | Class VI |

| Reverse | MSS SP-81 | 1.1 × rated | Class VI |

| Cycling | API 598 | 100 cycles | No degradation |

Installation & Engineering Services

Pre-Installation Services:

- Site Survey: Pipeline analysis and installation planning

- Foundation Design: Structural requirements and anchor bolt layouts

- Thermal Analysis: Expansion joint requirements and pipe stress analysis

- Flow Analysis: CFD modeling for optimal valve positioning

Installation Support:

- Rigging Plans: Certified lifting procedures for heavy valve assemblies

- Alignment Services: Precision alignment for optimal performance

- Testing Protocols: Complete commissioning and performance verification

- Documentation: As-built drawings and performance certificates

Maintenance & Service Support

Predictive Maintenance:

| Component | Monitoring | Frequency | Action |

|---|---|---|---|

| Seat Wear | Torque trending | Monthly | Replace at limit |

| Stem Condition | Visual inspection | Quarterly | Lubricate/adjust |

| Actuator | Performance data | Continuous | Trend analysis |

| Body Integrity | NDT inspection | Annual | Report findings |

Service Capabilities:

- Field Service: On-site maintenance and repair capabilities

- Refurbishment: Complete valve restoration to original specifications

- Upgrades: Actuator and control system modernization

- Training: Comprehensive maintenance training programs

Quality Certifications & Compliance

Manufacturing Standards:

- ISO 9001:2015 Quality Management System certification

- ISO 14001 Environmental Management System compliance

- OHSAS 18001 Occupational Health and Safety certification

- PED 2014/68/EU Pressure Equipment Directive compliance

Performance Standards:

- MSS SP-81 Knife Gate Valve Standard compliance

- AWWA C515 Large Diameter Valve Standard

- EN 12266-1 Industrial Valve Testing Standard

- API 598 Valve Inspection and Testing Standard

Contact TOT Valve today for technical consultation and competitive quotation on your DN1000 bidirectional knife gate valve requirements for ultra-large-diameter pipeline applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.