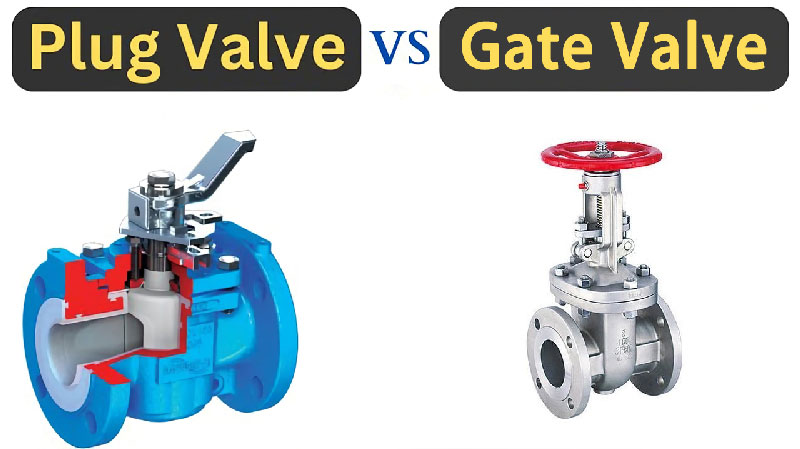

In industrial piping systems, valves play a critical role in controlling the flow of liquids, gases, and slurries. Among the many valve types, plug valves and gate valves are two common choices. While both are designed to stop or allow flow, they differ significantly in design, operation, performance, and applications.

This article compares plug valves vs. gate valves, helping you understand which is better suited for your system.

Table of Contents

ToggleWhat is a Plug Valve?

A plug valve is a quarter-turn valve that uses a cylindrical or conical plug with a hollow passage inside to control flow. When rotated 90°, the passage aligns with the pipe to allow flow, or turns perpendicular to block it.

Key Features of Plug Valves:

Quick Operation (90° turn)

Tight Sealing against leaks

Simple, compact design

Can handle gases, slurries, and corrosive fluids

What is a Gate Valve?

A gate valve is a linear-motion valve that uses a wedge-shaped or parallel gate to block or allow flow. The gate moves up and down perpendicular to the flow, making it suitable for full shutoff applications.

Key Features of Gate Valves:

Slow Operation (multi-turn)

Minimal pressure drop when fully open

Ideal for on/off service, not throttling

Common in water supply, oil & gas, and power plants

Plug Valve vs. Gate Valve: Side-by-Side Comparison

| Feature | Plug Valve | Gate Valve |

|---|---|---|

| Operation | Quarter-turn (90°) | Multi-turn (handwheel, rising stem) |

| Flow Control | Suitable for throttling & on/off | Best for on/off only (not for throttling) |

| Sealing | Tight seal, good for gas & slurry | Good sealing for liquids, not ideal for gases |

| Speed | Fast operation | Slower operation |

| Pressure Drop | Moderate (due to plug obstruction) | Very low when fully open |

| Durability | More prone to wear (friction between plug & seat) | Durable for infrequent operation |

| Applications | Chemical plants, oil & gas, slurry handling | Water supply, oil pipelines, power generation |

| Maintenance | Requires more frequent lubrication | Lower maintenance frequency |

| Size Range | Commonly small to medium | Suitable for medium to large diameters |

When to Use a Plug Valve

Quick shutoff is required

Handling gases, slurries, or corrosive fluids

Applications needing compact valves with reliable sealing

Industries: Chemical, petrochemical, wastewater, pulp & paper

When to Use a Gate Valve

Full flow with minimal pressure drop is needed

System is used infrequently (valve left open/closed most of the time)

Suitable for large-diameter pipelines

Industries: Water treatment, oil & gas, power plants, fire protection

Conclusion

Both plug valves and gate valves serve important roles in industrial piping.

Choose a plug valve if you need fast operation, tight sealing, and reliable performance with gases or slurries.

Choose a gate valve if you require low pressure loss, durability, and large-diameter shutoff control.

The final choice depends on your system’s medium, pressure, operating frequency, and budget.