In fluid control systems, ball valves and globe valves are two of the most widely used valve types. At first glance, both seem to serve the same purpose: controlling the flow of liquids or gases. However, they are designed for different functions, performance characteristics, and applications.

This guide will help you understand the differences between ball valves and globe valves, so you can make the right choice for your project.

Table of Contents

ToggleWhat is a Ball Valve?

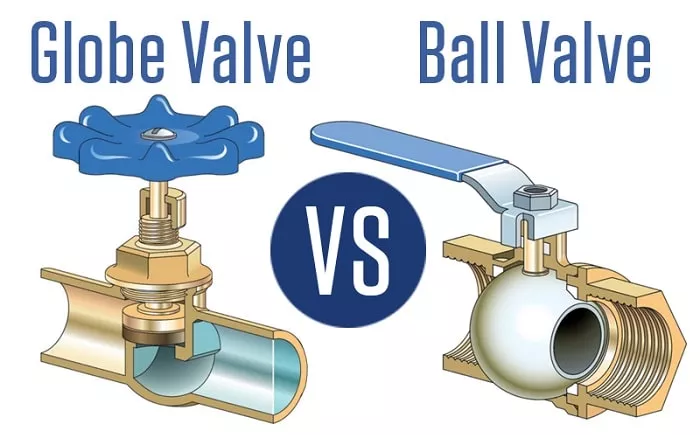

A ball valve uses a rotating ball with a hole (bore) through the center to control flow. When the bore aligns with the pipeline, the valve is open; when rotated 90°, the flow is blocked.

Advantages of Ball Valves:

Quick quarter-turn operation (fast shut-off).

Compact, lightweight design.

Excellent sealing, minimal leakage.

Low pressure drop when fully open.

Long service life, low maintenance.

Disadvantages of Ball Valves:

Poor throttling (flow regulation is not precise).

Can wear faster if used for frequent modulation.

Not ideal for high-pressure drops or slurry applications.

Typical Applications:

Oil & gas pipelines

Water distribution

HVAC systems

Chemical industries

What is a Globe Valve?

A globe valve uses a disc or plug that moves up and down against the flow to control fluid passage. It is named for its spherical body shape.

Advantages of Globe Valves:

Excellent for throttling and flow regulation.

Precise control over flow rate.

Strong sealing capability.

Suitable for high-pressure and high-temperature systems.

Disadvantages of Globe Valves:

Higher pressure drop due to flow path changes.

Slower operation (multi-turn handle or actuator).

Larger and heavier compared to ball valves.

More expensive in many cases.

Typical Applications:

Power plants (steam, cooling water systems).

Chemical processing.

Boiler feedwater systems.

Water treatment plants.

Ball Valve vs Globe Valve: Comparison Table

| Feature | Ball Valve | Globe Valve |

|---|---|---|

| Design | Rotating ball with bore | Disc/plug moves perpendicular to flow |

| Operation | 90° turn (quarter-turn) | Multi-turn (linear motion) |

| Flow Control | Best for on/off | Best for throttling/regulation |

| Sealing | Tight shut-off | Good shut-off but less than ball valve |

| Pressure Drop | Very low when open | Higher due to flow path |

| Durability | Long life, less wear | More wear due to throttling use |

| Size/Weight | Compact, lightweight | Larger and heavier |

| Cost | Generally lower | Higher, especially in large sizes |

| Applications | Pipelines, quick shut-off | Precise flow regulation |

When to Choose Ball Valves vs Globe Valves

✅ Choose a Ball Valve if: You need quick shut-off, minimal pressure drop, compact design, and low maintenance.

✅ Choose a Globe Valve if: You need precise flow regulation, throttling control, or are working with high-pressure/high-temperature systems.

Conclusion

While both ball valves and globe valves play crucial roles in fluid control, their functions are distinct:

Ball valves excel in on/off shut-off applications.

Globe valves are best for flow regulation and throttling.

The right choice depends on whether your priority is speed and tight shut-off (ball valve) or precision flow control (globe valve).