Table of Contents

ToggleWhat is a Needle Valve?

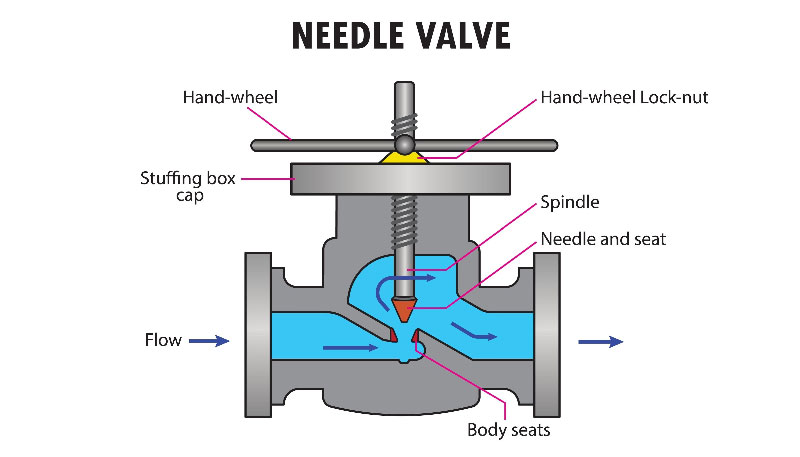

A needle valve is a type of small, precision valve used for fine-tuning the flow of a fluid. Unlike common valves designed for simple on/off control, the needle valve’s primary function is accurate flow regulation. It is named for its main component: a long, slender stem with a tapered, needle-like end that fits perfectly into a corresponding seat.

How It Works

The magic of a needle valve lies in its simple yet highly effective design. The valve operates by turning a handwheel that slowly raises or lowers a needle-shaped stem relative to its seat.

- As the stem is slowly withdrawn, a tiny annular orifice is created between the needle tip and the valve seat.

- By turning the handwheel, the size of this opening can be gradually and precisely increased or decreased.

This design allows for meticulous control over the flow rate, making it an ideal choice for applications where even a small change in flow is significant. The gradual change in the orifice size provides a far greater degree of control than other valve types.

Pros and Cons of Needle Valves

To understand when to use a needle valve, consider its key advantages and limitations.

- Advantages:

- Excellent Flow Control: This is the needle valve’s defining feature. It provides a smooth, gradual adjustment from minimal to maximum flow.

- High Precision: The fine-threaded stem allows for incredibly accurate and repeatable flow settings.

- Compact Design: Needle valves are generally small and compact, making them easy to install in tight spaces.

- Good Sealing: The tapered stem provides a tight, reliable seal when fully closed.

- Disadvantages:

- Slow Operation: It takes many turns to fully open or close the valve, making it unsuitable for quick on/off applications.

- High Pressure Drop: The narrow flow path creates significant resistance and pressure loss across the valve.

- Susceptible to Damage: Solid particles in the fluid can damage the delicate needle tip and seat, affecting both its sealing and control precision.

Comparison with Other Valves

A needle valve’s purpose is distinct from other common valve types:

- Needle Valve vs. Ball Valve: While a ball valve is perfect for quick on/off control, it provides very poor throttling, making it unsuitable for flow regulation. A needle valve is the exact opposite: excellent for control, terrible for speed.

- Needle Valve vs. Gate Valve: Gate valves are used for full-open or full-closed service and are not designed for throttling. They are intended for applications where the valve should be either fully on or fully off.

Common Applications

Because of their unique ability to provide precise control, needle valves are essential in many specialized applications.

- Instrumentation: They are often used as instrumentation valves to control the flow of gases or liquids to gauges and analyzers.

- Chemical Analysis: In laboratories and chemical plants, needle valves are used to precisely regulate the flow of reagents for accurate mixing and sampling.

- Hydraulic and Pneumatic Systems: They are critical components in systems that require precise control over actuator speed and pressure.

In summary, when your primary need is a tight shut-off and, more importantly, unmatched precision in flow control, the needle valve is the ideal choice.