Valves are essential components in fluid control systems, widely used in industrial pipelines, power plants, water treatment, and process engineering. Each valve type operates based on a unique mechanism that controls the flow, pressure, or direction of fluids. This article provides a detailed explanation of common valve types and their working principles.

Table of Contents

Toggle1. Gate Valve

A gate valve (also known as a sluice valve) operates by lifting or lowering a flat or wedge-shaped gate to start or stop the flow of fluid.

When the gate is fully lifted, it allows unobstructed flow, resulting in minimal pressure loss.

Features:

Low flow resistance and bidirectional sealing.

Simple structure, suitable for both small and large diameters.

Not ideal for throttling applications.

Types:

Rising stem (visible stem movement)

Non-rising stem (concealed stem)

Parallel or wedge-type gates

Gate valves are primarily used for on-off applications, not for regulating flow.

2. Globe Valve

The globe valve (also known as a stop valve) controls flow by moving a disc or plug against the flow direction.

It offers excellent throttling performance and reliable sealing.

Advantages:

Precise flow control

Strong sealing capability

Suitable for high-pressure applications

Limitations:

Higher flow resistance than gate valves

Flow direction must follow the arrow marked on the body

Types:

Straight type, angle type, and Y-pattern globe valves.

Globe valves are widely used in pipelines where flow regulation and frequent operation are required.

3. Butterfly Valve

A butterfly valve uses a circular disc (the “butterfly”) that rotates around a central axis to open or close the flow.

It is lightweight, compact, and ideal for large-diameter pipelines.

Key Benefits:

Quick 90° rotation for full open/close

Compact structure and low cost

Suitable for both throttling and shut-off

Butterfly valves are commonly used in HVAC systems, water supply, and chemical pipelines.

4. Ball Valve

The ball valve operates by rotating a spherical ball with a bore through its center. When the bore aligns with the pipeline, fluid flows freely; when perpendicular, flow stops.

Advantages:

Tight sealing and zero leakage

Easy operation and minimal maintenance

Low pressure drop when fully open

Types:

Floating ball valve

Trunnion-mounted ball valve

Ball valves are ideal for applications requiring fast shut-off and reliable sealing, such as gas and water systems.

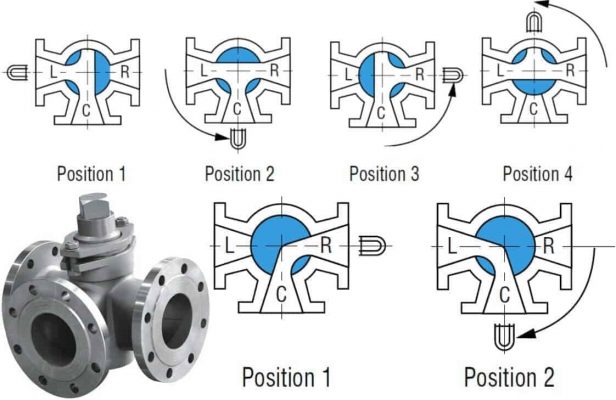

5. Plug Valve

A plug valve uses a cylindrical or conical plug that rotates within the valve body to control flow.

It provides a simple design and quick operation, requiring only a 90° turn.

Applications:

On-off control

Diverting or mixing service (three-way or four-way plug valves)

Limitations:

Frequent operation may cause sealing wear, making it less suitable for throttling or high-temperature service.

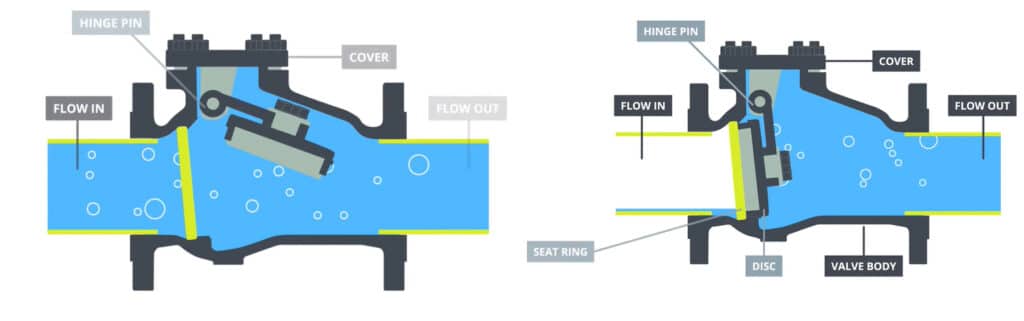

6. Check Valve (Non-Return Valve)

The check valve automatically prevents backflow using the pressure of the fluid itself.

When flow reverses, the valve disc closes automatically.

Types:

Lift check valve (vertical or horizontal)

Swing check valve (single or double disc)

Commonly used in pump discharge lines, it protects equipment by ensuring one-way flow.

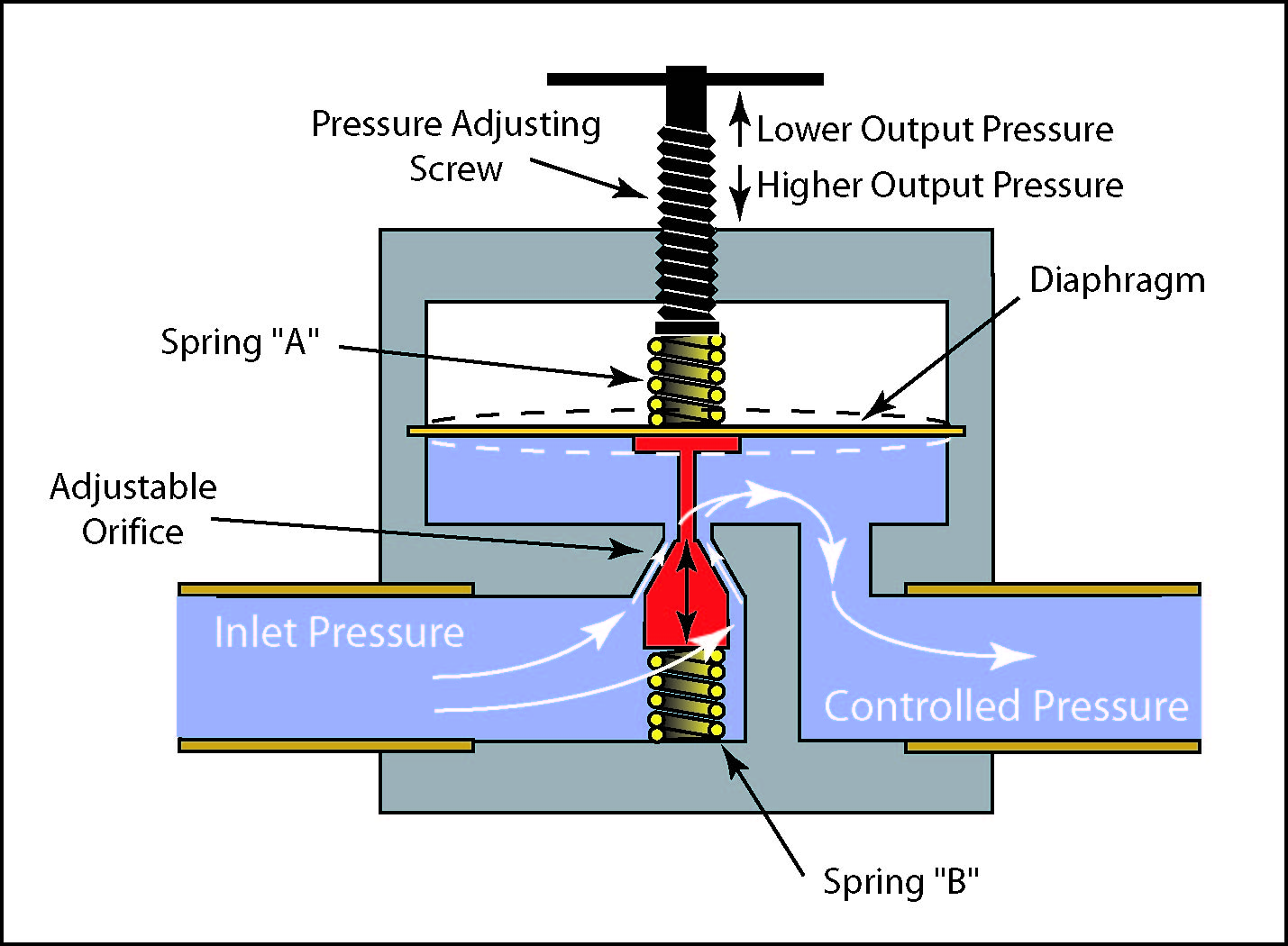

7. Pressure Reducing Valve

A pressure reducing valve automatically lowers upstream pressure to a stable downstream value.

Two main types are:

Piston type

Spring-diaphragm type

These valves are widely used in steam, gas, and water systems to maintain consistent outlet pressure.

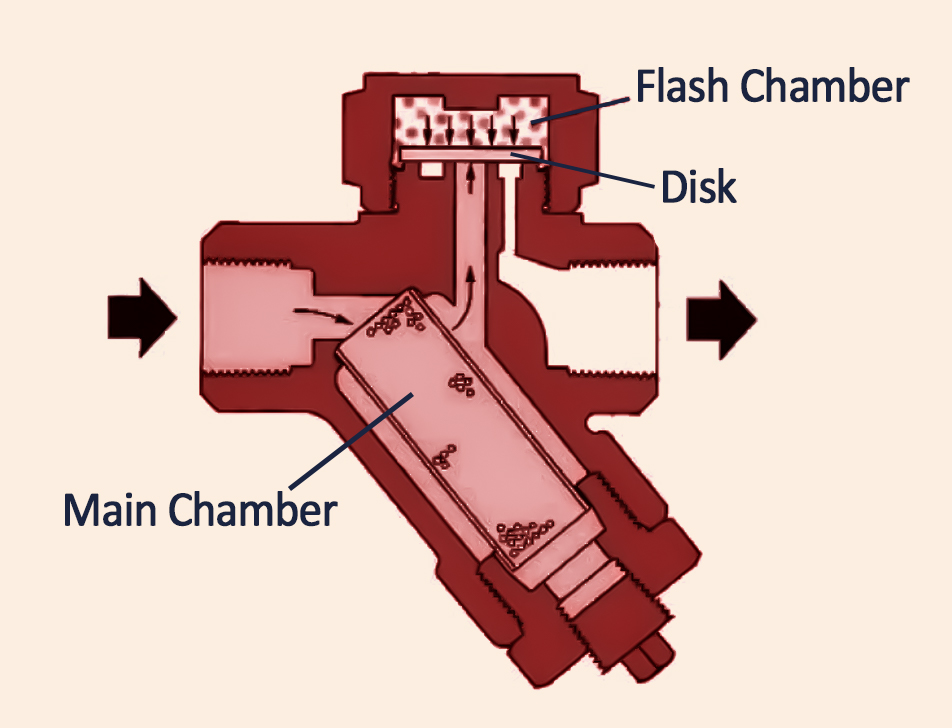

8. Steam Trap (Condensate Drain Valve)

A steam trap automatically discharges condensate without letting steam escape.

It distinguishes condensate from steam based on density, temperature, or phase change.

Main Types:

Mechanical type (float and bucket)

Thermostatic type (bimetal or bellows)

Thermodynamic type

Steam traps are essential in steam heating systems to maintain efficiency and prevent energy loss.

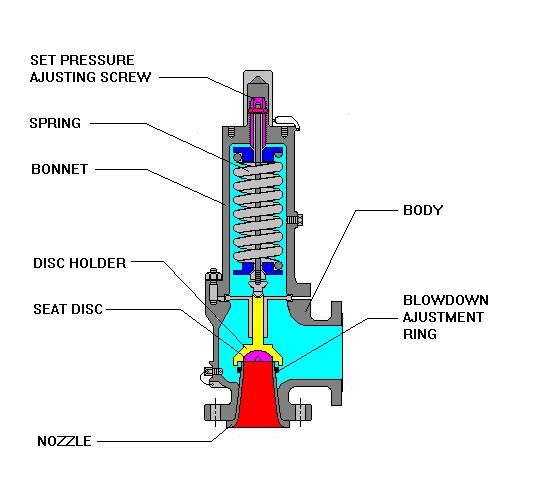

9. Safety Valve

The safety valve protects pressure vessels and pipelines by automatically releasing excess pressure when it exceeds the set limit.

Working Principle:

When the internal pressure surpasses the spring force, the valve disc lifts, venting fluid until pressure returns to normal.

Common Designs:

Spring-loaded safety valve

Lever-type safety valve

Safety valves are critical in boilers, pressure vessels, and air compressors for overpressure protection.

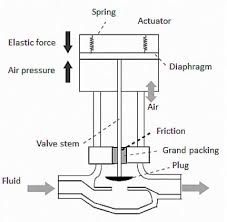

10. Control Valve

Control valves regulate flow, pressure, or level automatically according to control signals from process systems.

By actuation type:

Pneumatic control valve

Electric control valve

Hydraulic control valve

By motion type:

Linear (globe, diaphragm)

Rotary (ball, butterfly)

Control valves are integral to automation and process control systems, ensuring stable operation and precision.

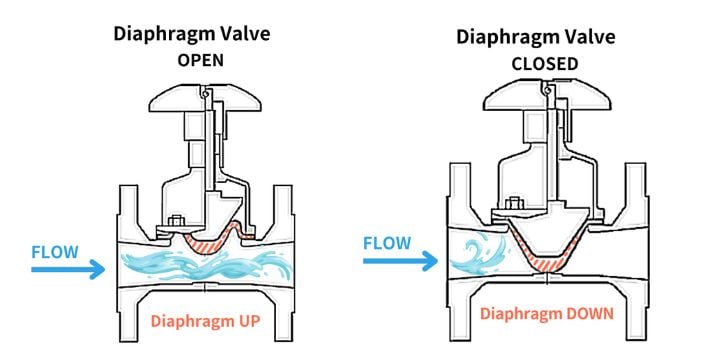

11. Diaphragm Valve

A diaphragm valve uses a flexible diaphragm pressed against a seat to control flow.

It’s ideal for corrosive, viscous, or slurry fluids, as it isolates the medium from the moving parts.

Advantages:

Leak-free operation

Excellent corrosion resistance

Simple structure and easy maintenance

Limitations:

Not suitable for high-pressure or high-temperature conditions.

Common Materials:

Rubber-lined diaphragm valve

PTFE-lined diaphragm valve

Plastic diaphragm valve

Conclusion

Each valve type has unique advantages, limitations, and ideal applications.

Understanding their working principles and structural differences is essential for selecting the right valve for your system. Whether it’s fluid isolation, pressure control, backflow prevention, or automation — the right valve ensures safety, efficiency, and reliability in every industrial process.