Industrial Large Diameter Valves Manufacturer

What are Large Diameter Valves? Large diameter valves are critical-service shutoff and control valves with a nominal diameter typically DN700 and above. They are specifically engineered to manage high-volume flow and pressure in large-scale industrial pipelines. Unlike standard-sized valves, large diameter valves require specialized design and robust construction to handle extreme forces, ensuring reliable and safe operation in demanding environments.

When your system requires a dependable solution for controlling massive fluid or slurry flows, standard valves simply won’t suffice. As an industrial buyer, you need valves that combine precise engineering with exceptional durability, all from a supplier who understands the unique challenges of your industry. That’s where we come in.

At TOT Valve, we manufacture and supply industrial-grade large diameter valves built for superior performance and long-term reliability. We specialize in sizes DN700 and larger, serving critical applications in waterworks, power generation, mining, and oil & gas.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Why Choose Our Large Diameter Valves?

You might be wondering: “Why are large diameter valves so specialized?” The following are some factors we have summarized based on experience for your reference:

Engineered for Extreme Conditions Built to handle immense pressure and flow, our large diameter valves ensure system integrity and safety.

Superior Sealing Performance Our designs incorporate advanced sealing technology to guarantee a tight, leak-proof shutoff, even under high pressure.

Enhanced Durability Constructed from heavy-duty materials with robust components, our valves offer extended service life and minimal maintenance requirements.

Reduced Pressure Loss With full-bore designs, our valves ensure unobstructed flow, which minimizes energy consumption and maximizes system efficiency.

Customized Solutions We offer bespoke designs and material options to perfectly match your specific media, temperature, and pressure conditions.

Applications of Large Diameter Valves

Large diameter valves are essential in various industries where managing high-volume flow is critical:

Water & Wastewater Management

Power Generation Plants

Mining and Mineral Processing

Pulp & Paper Manufacturing

Oil & Gas Pipelines

Large-Scale HVAC Systems

Types of Large Diameter Valves We Offer

Large diameter valves play a vital role in most industrial control systems. We focus on two main types, each with unique functions and advantages to meet your specific industrial needs:

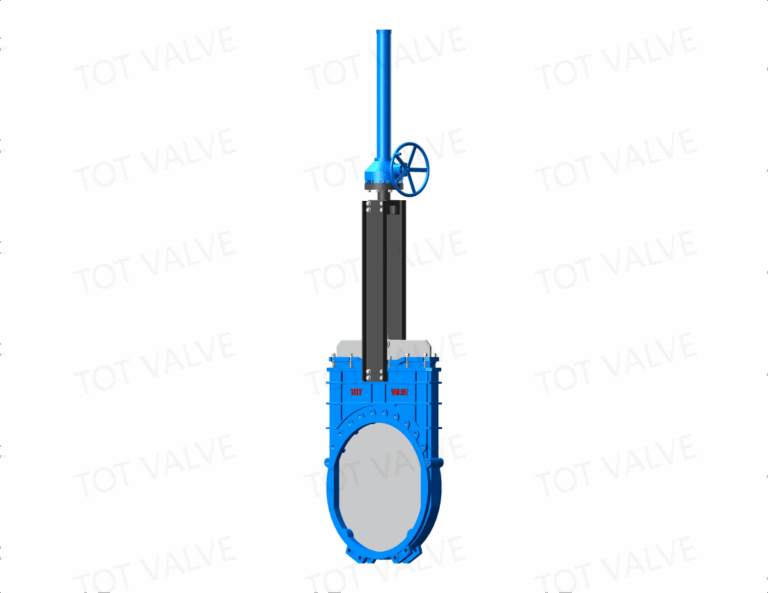

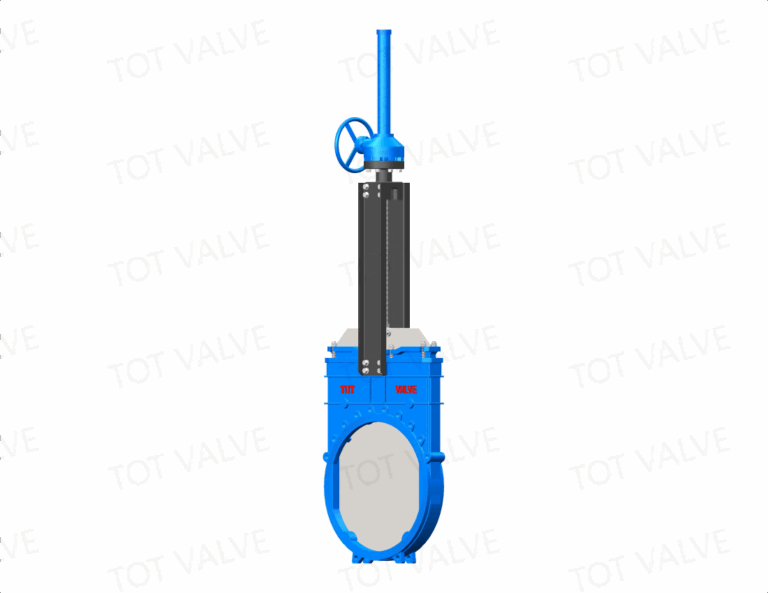

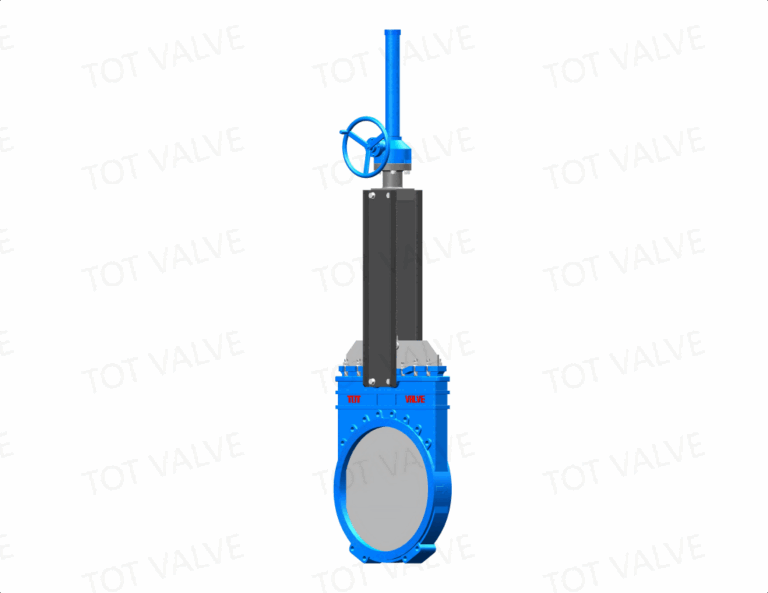

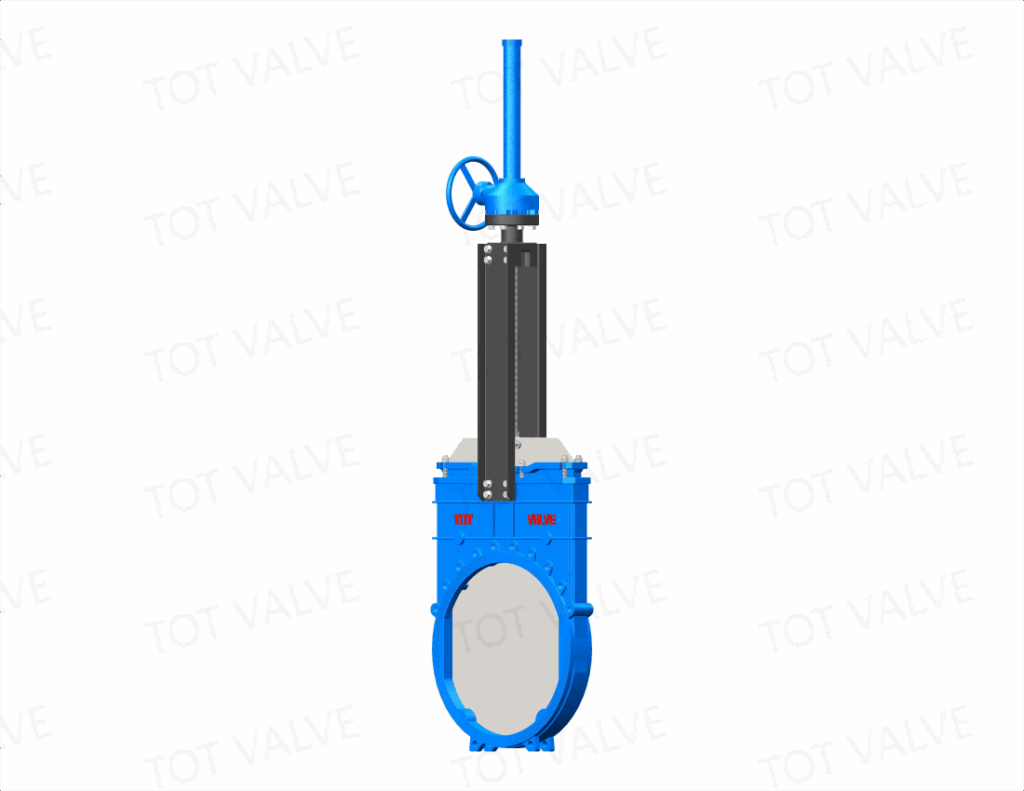

Designed for the toughest applications, our knife gate valves cut through thick, abrasive media. Their sharp gate and robust sealing mechanism provide reliable shutoff in environments where other valves would fail. Ideal for slurry, viscous fluids, and bulk solids.

Our butterfly valves are a preferred choice for their compact design and efficient quarter-turn operation. They provide precise and fast control of large volumes of media, making them suitable for water, air, and low-viscosity fluids.

* We are not just providing simple quotes but experts in selection, calculation, and drawing.

Large Diameter Valves Data Sheet

We offer our large diameter valves in a variety of robust materials tailored to your media, temperature, and pressure needs.

| Material | Best For | Features |

| Carbon Steel | General industrial use, water & wastewater | High strength, cost-effective, durable construction |

| Stainless Steel (304/316) | Corrosive chemicals, food-grade, marine | Excellent resistance to rust, acids, and harsh environments |

| Ductile Iron | Waterworks, municipal infrastructure | High strength, toughness, and good corrosion resistance |

| Special Alloys | High-temperature, highly corrosive media | Custom options for extreme operational conditions |

If you're unsure which material suits your line conditions, our engineering team will guide you through the selection.

| Parameter | Options / Ranges |

| Size Range | DN700 to DN2000 (and larger on request) |

| Pressure Rating | PN10 to PN40 (150 LB to 300 LB) |

| Temperature Rating | Up to 400°C (material dependent) |

| Connection Types | Flanged, Welded |

| Valve Type | Knife Gate Valves, Butterfly Valves |

| Standards Compliance | API 609, AWWA C504, ASME B16.34, CE |

| Seat Material | Application | Features |

| EPDM / NBR | Water, wastewater, general industrial use | Excellent elasticity and sealing, good for low-to-moderate temperatures. |

| Metal Seats | High temperature, high pressure, abrasive media | Designed for severe service where soft seats are not suitable, offering exceptional durability. |

| PTFE (Teflon) | Corrosive chemicals, food-grade applications | Superior chemical resistance and non-stick properties. |

| Ceramic | Highly abrasive or corrosive media | Extreme wear resistance, ideal for mining and slurry applications. |

FAQ

We define large diameter valves as having a nominal diameter of DN700 and above.

Yes, our engineering team can work with you to design and manufacture custom valves tailored to your unique specifications.

For abrasive media, we highly recommend our large diameter knife gate valves with specialized gate and seat materials to ensure durability and a reliable seal.

Our valves are built to international standards (e.g., API, ASME) and can be certified to meet specific project requirements upon request.