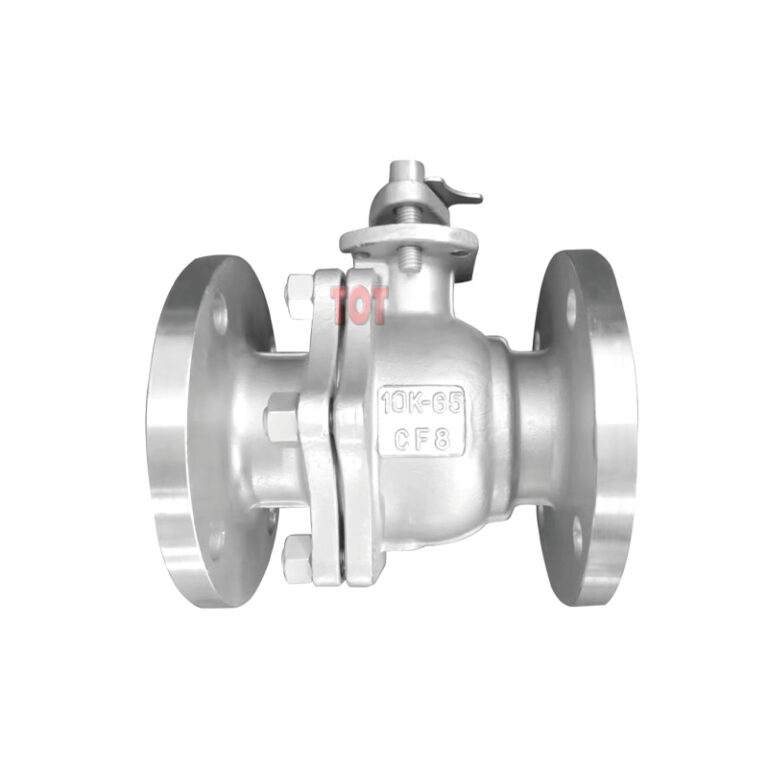

3″ Stainless Steel 3-Way Ball Valve

High-performance 3-inch three-way ball valve manufactured from premium stainless steel, designed for reliable flow control in demanding industrial applications. Features full port design for maximum flow capacity and minimal pressure drop.

Key Features

- Material: 316 Stainless Steel body and trim

- Size: 3 inch (DN80)

- Port Configuration: Full port, three-way (L-port or T-port)

- Operation: Manual lever handle (motorized actuator ready)

- Pressure Rating: 1000 WOG (Water, Oil, Gas)

- Temperature Range: -20°F to +400°F (-29°C to +204°C)

- End Connections: NPT threaded or flanged (ANSI 150#)

Technical Specifications

Dimensions & Weights

- Valve Size: 3″ (80mm)

- Overall Length: 6.5″ (165mm)

- Overall Height: 4.2″ (107mm)

- Weight: 12 lbs (5.4 kg)

- Cv Value: 280 (full open)

Materials of Construction

- Body: CF8M/316 Stainless Steel

- Ball: CF8M/316 Stainless Steel

- Stem: 316 Stainless Steel

- Seats: PTFE (Teflon) with spring energized design

- O-Rings: Viton (FKM)

- Handle: Stainless Steel with locking capability

Pressure & Temperature Ratings

- Working Pressure: 1000 PSI @ 70°F

- Hydrostatic Test: 1500 PSI

- Maximum Temperature: 400°F (204°C)

- Minimum Temperature: -20°F (-29°C)

Flow Configurations

L-Port Configuration

- Function: Diverts flow 90° – connects inlet to either outlet

- Applications: Flow diversion, bypass systems

- Flow Pattern: Inlet to Port A OR Inlet to Port B

T-Port Configuration

- Function: Connects all three ports simultaneously or blocks flow

- Applications: Mixing, distribution, shut-off

- Flow Pattern: Inlet to both outlets OR complete shut-off

Applications

- Chemical Processing: Corrosive fluid handling

- Pharmaceutical: Sanitary applications

- Food & Beverage: CIP/SIP systems

- Water Treatment: Distribution and bypass

- HVAC Systems: Heating/cooling circuits

- Marine: Seawater applications

- Oil & Gas: Upstream/downstream processing

Standards & Certifications

- Design Standard: API 608, ASME B16.34

- Face-to-Face: ASME B16.10

- End Connections: ASME B16.5 (Flanged), ASME B1.20.1 (NPT)

- Fire Safe: API 607/API 6FA

- Testing: API 598

- Material Certification: ASTM A351 CF8M

- Quality System: ISO 9001:2015

Installation & Maintenance

Installation Requirements

- Install with stem in horizontal position preferred

- Ensure adequate clearance for handle operation

- Support piping independently – do not use valve as pipe support

- Use appropriate gaskets and sealants for application

Maintenance Schedule

- Quarterly: Visual inspection for leaks

- Annually: Actuate valve through full range

- Every 3 Years: Replace seats and seals (depending on service)

- Every 5 Years: Complete valve overhaul

Ordering Information

Standard Options

- End Connections: NPT threaded, 150# RF flanged, 300# RF flanged

- Port Type: L-Port or T-Port configuration

- Handle: Standard lever, extended lever, lockable lever

- Actuator Ready: ISO 5211 mounting pad available

Model Numbers

- SS3BV-L-NPT: 3″ L-Port, NPT threaded ends

- SS3BV-T-NPT: 3″ T-Port, NPT threaded ends

- SS3BV-L-150F: 3″ L-Port, 150# flanged ends

- SS3BV-T-150F: 3″ T-Port, 150# flanged ends

Optional Accessories

- Pneumatic Actuator: Double-acting, spring return options

- Electric Actuator: 120V, 240V, 480V available

- Position Indicators: Visual/electrical feedback

- Limit Switches: SPDT contact configuration

- Mounting Brackets: For actuator installation

Quality Assurance

Every valve is factory tested and includes:

- Pressure Test Certificate

- Material Traceability Documentation

- Dimensional Inspection Report

- Performance Test Data

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.