API 609 Butterfly Valves

TOT Valve specializes in API 609 butterfly valves. We use high-quality CF8/CF8M/CF3/CF3M stainless steel that meets ASTM A351 standards and use soft-seal valve seats such as PTFE, RPTFE, PFA, FEP, etc.

The advantages of our API 609 butterfly valves are not limited to zero leakage, low torque operation and long service life. You can also have a wide range of applications. With bidirectional sealing and fireproof options, our butterfly valves can ensure the reliability and efficiency of your industrial applications in harsh environments.

Explore our API 609 valves, get the most competitive prices in the market.

API 609 standard is the American Petroleum Institute’s requirements for the design, manufacture, materials and testing of butterfly valves. Its main purpose is to ensure that butterfly valves maintain their performance and reliability in industrial applications.

The stainless steel butterfly valves we provide are manufactured strictly in accordance with API 609 standard. Each valve is tested and checked in accordance with API 598 standard before being packaged into boxes to ensure that it is 100% qualified product when it is delivered to you.

This standard covers three main valve body types:

– Wafer Type Butterfly Valve

– Lug Type Butterfly Valve

– Flanged Type Butterfly Valve(Single/Double Flange)

– Welded Butterfly Valve

API 609 Butterfly Valve Standard

| Design and Manufacturing | Face to Face | End Flanges | Butt Welding Ends | Inspection & Testing |

|---|---|---|---|---|

| EN593, API 609, ASME B16.34 | ASME B16.10/API 609 | ASME B16.5/ASME B16.47 | ASME B16.25 | API 598 |

API 609 Butterfly Valve Benefits

- Compact design saves space

- Less friction between seat and disc

- “Zero leakage” seal design

- One-piece explosion-proof shaft

- Low torque makes actuator more compact and longer cycle life

- Optional stem extension, optional locking device

- Standard laminated elastomeric disc seal, high temperature resistant to 600°C

- Minimum moving parts, low maintenance cost

- Easy to automate

API 609 Category A vs Category B – What’s the Difference?

Choosing the right API 609 butterfly valve standard can ensure the compatibility, reliability and long-term cost-effectiveness of your application.

The API 609 butterfly valve standard is divided into Category A and Category B according to the structure. Category A is a concentric butterfly valve, and Category B is an eccentric butterfly valve (double eccentric, triple eccentric). Below we summarize the differences between them, hope it will be helpful to you.

| Feature | Category A | Category B |

| Valve Type | Resilient-seated butterfly valve | High-performance butterfly valve |

| Design | Concentric disc design (zero offset) | Typically double-offset or triple-offset disc design |

| Body Material | Stainless Steel(SS304/SS316L/CF8/CF8M) , Duplex Stainless Steel(2507/1.4529) | |

| Disc Material | Stainless Steel(SS304/SS316L/CF8/CF8M) , Duplex Stainless Steel(2507/1.4529) | |

| Seating Material | Soft seat (rubber, EPDM, PTFE, etc.) | Metal seat or fire-safe seat (can be soft-metal combination) |

| Actuator Options | Lever, Worm Gear, Electric Actuator, Pneumatic Actuator. | |

| Pressure Ratings | Primarily ANSI Class 150 | ANSI Class 150 & Class 300 |

| Temperature Range | Moderate (typically below 120°C) | Wider range, suitable for high temperature and high pressure |

| Applications | Water, air, non-corrosive media | Steam, gas, chemicals, high-pressure liquids |

| Shut-off Performance | Good for low-pressure tight shut-off | Excellent sealing under high pressure and temperature |

| Typical Connection | Wafer or lug type | Lug or double-flanged type |

| Cost | Lower | Higher (due to material and precision design) |

| Usage Frequency | Best for low-cycling systems | Suitable for frequent operation in demanding systems |

| Standards Applied | API 609 Category A (Wafer/Lug style) | API 609 Category B (High-Performance design) |

*As you know, the price of API 609 butterfly valve requires relatively complex combination calculation. If you want to buy API 609 valves from China or have other questions, please contact us immediately, we are always ready to answer you.

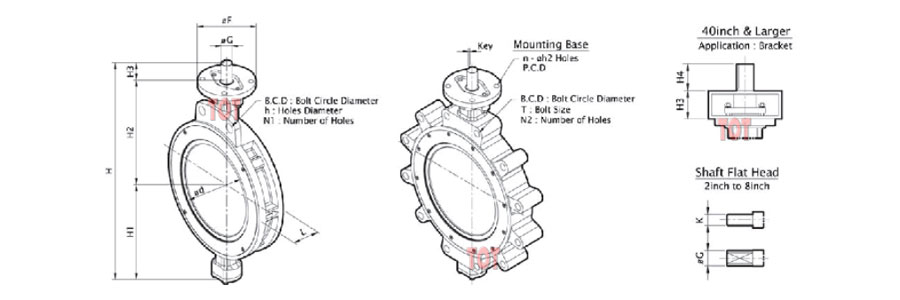

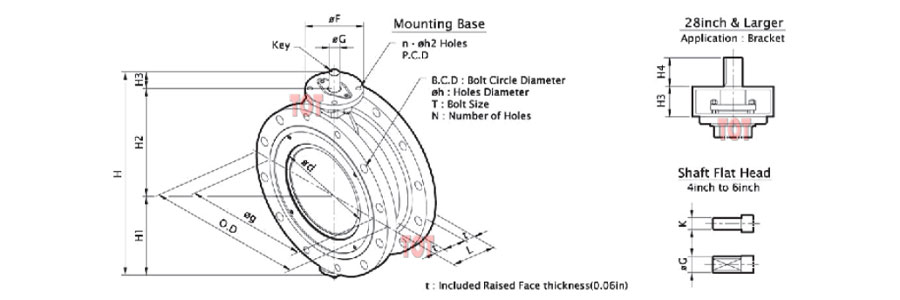

API 609 Butterfly Valve Dimensions

When you purchase butterfly valves for industrial use, dimensional accuracy is not optional, but critical. The API 609 standard not only defines the performance and material requirements of butterfly valves, but also ensures standardized dimensions for global compatibility, installation efficiency, and process safety. Refer to the API 609 butterfly valve dimensions summarized by TOT Valve below, I hope it will be helpful to you.

API 609 Category A

| Size(inch) | Φd | L | H | H1 | H2 | H3 | H4 | K | ΦG | ΦF | B.C.D. | ΦH | T | N1 | N2 | P.C.D. | Φh2 |

| 2 | 1.85 | 1.69 | 10.12 | 3.94 | 4.92 | 1.26 | – | 0.374 | 0.551 | 4.02 | 4.75 | 0.750 | 5/8″x11unc | 2 | 4 | 3.25 | 0.43 |

| 2.5 | 2.40 | 1.85 | 11.15 | 4.02 | 5.87 | 1.26 | – | 0.437 | 0.626 | 4.02 | 5.50 | 0.750 | 5/8″x11unc | 2 | 4 | 3.25 | 0.43 |

| 3 | 2.83 | 1.89 | 11.97 | 4.41 | 6.30 | 1.26 | – | 0.437 | 0.626 | 4.02 | 6.00 | 0.750 | 5/8″x11unc | 2 | 4 | 3.25 | 0.43 |

| 4 | 3.74 | 2.13 | 13.15 | 4.88 | 7.01 | 1.26 | – | 0.500 | 0.748 | 4.02 | 7.50 | 0.750 | 5/8″x11unc | 2 | 8 | 3.25 | 0.43 |

| 5 | 4.65 | 2.24 | 14.41 | 5.55 | 7.60 | 1.26 | – | 0.500 | 0.748 | 4.02 | 8.50 | 0.875 | 3/4″x10unc | 2 | 8 | 3.25 | 0.43 |

| 6 | 5.43 | 2.24 | 16.22 | 6.57 | 8.39 | 1.26 | – | 0.500 | 0.748 | 4.02 | 9.50 | 0.875 | 3/4″x10unc | 2 | 8 | 3.25 | 0.43 |

| 8 | 7.40 | 2.52 | 18.39 | 7.68 | 9.45 | 1.26 | – | 0.626 | 0.874 | 5.98 | 11.75 | 0.875 | 3/4″x10unc | 2 | 8 | 5.00 | 0.55 |

| 10 | 9.25 | 2.83 | 21.73 | 8.66 | 11.02 | 2.05 | – | 0.25×0.25 | 1.126 | 5.98 | 14.25 | 1.000 | 7/8″x9unc | 2 | 12 | 5.00 | 0.55 |

| 12 | 10.83 | 3.19 | 24.64 | 10.43 | 12.20 | 2.01 | – | 0.25×0.25 | 1.126 | 5.98 | 17.00 | 1.000 | 7/8″x9unc | 2 | 12 | 5.00 | 0.55 |

| 14 | 12.48 | 3.62 | 27.24 | 11.81 | 13.19 | 2.24 | – | 0.31×0.31 | 1.374 | 5.98 | 18.75 | 1.125 | 1″x8unc | 2 | 12 | 5.00 | 0.55 |

| 16 | 14.13 | 4.02 | 31.85 | 13.39 | 15.47 | 2.99 | – | 0.50×0.50 | 1.874 | 8.03 | 21.25 | 1.125 | 1″x8unc | 2 | 16 | 6.50 | 0.83 |

| 18 | 16.38 | 4.49 | 34.56 | 14.76 | 16.81 | 2.99 | – | 0.50×0.50 | 1.874 | 8.03 | 22.75 | – | 1 1/8″x8un | 4 | 16 | 6.50 | 0.83 |

| 20 | 18.39 | 5.00 | 36.46 | 15.75 | 17.72 | 2.99 | – | 0.50×0.50 | 2.126 | 8.03 | 25.00 | – | 1 1/8″x8un | 4 | 20 | 6.50 | 0.83 |

| 22 | 20.00 | 6.06 | 40.63 | 17.32 | 19.29 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 27.25 | – | 1 1/4″x8un | 4 | 20 | 10.00 | 0.75 |

| 24 | 21.57 | 6.06 | 43.59 | 18.70 | 20.87 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 29.50 | – | 1 1/4″x8un | 4 | 20 | 10.00 | 0.75 |

| 26 | 23.11 | 6.50 | 46.14 | 19.88 | 22.24 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 31.75 | – | 1 1/4″x8un | 4 | 24 | 10.00 | 0.75 |

| 28 | 25.12 | 6.50 | 49.49 | 21.85 | 23.62 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 34.00 | – | 1 1/4″x8un | 4 | 28 | 10.00 | 0.75 |

| 30 | 27.01 | 7.48 | 52.87 | 23.03 | 25.39 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 36.00 | – | 1 1/4″x8un | 4 | 28 | 10.00 | 0.75 |

| 32 | 28.94 | 7.48 | 55.04 | 24.21 | 26.38 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 38.50 | – | 1 1/2″x8un | 4 | 28 | 10.00 | 0.75 |

| 34 | 30.83 | 7.99 | 58.19 | 26.18 | 27.56 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 40.50 | – | 1 1/2″x8un | 4 | 32 | 10.00 | 0.75 |

| 36 | 33.03 | 7.99 | 59.57 | 26.38 | 28.74 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 42.75 | – | 1 1/2″x8un | 4 | 32 | 10.00 | 0.75 |

| 38 | 35.43 | 8.50 | 62.33 | 28.35 | 29.53 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 45.25 | – | 1 1/2″x8un | 4 | 32 | 10.00 | 0.75 |

| 40 | 37.32 | 8.50 | 70.59 | 29.84 | 30.12 | 5.91 | 4.72 | – | 1.10×0.63 | 3.933 | 47.25 | – | 1 1/2″x8un | 8 | 36 | 11.73 | 0.91 |

| 42 | 39.45 | 9.49 | 72.83 | 31.10 | 30.71 | 6.30 | 4.72 | – | 1.10×0.63 | 3.933 | 49.50 | – | 1 1/2″x8un | 8 | 36 | 11.73 | 0.91 |

| 48 | 44.37 | 10.00 | 81.69 | 35.43 | 34.65 | 6.30 | 5.31 | – | 1.26×0.71 | 4.720 | 56.00 | – | 1 1/2″x8un | 8 | 44 | 11.73 | 0.91 |

API 609 Category B

| Class 150 | |||||||||||||||||||

| Size(inch) | ød | L | O.D. | øg | t | H | H1 | H2 | H3 | H4 | K | øg | of | B.C.D. | øh | T | N | P.C.D. | øh2 |

| 4 | 3.74 | 5.04 | 9.00 | 6.19 | 0.94 | 13.15 | 4.88 | 7.01 | 1.26 | – | 0.500 | 0.748 | 4.02 | 7.50 | 0.750 | 5/8″x11unc | 8 | 3.25 | 0.43 |

| 5 | 4.65 | 5.51 | 10.00 | 7.31 | 0.94 | 14.41 | 5.55 | 7.60 | 1.26 | – | 0.500 | 0.748 | 4.02 | 8.50 | 0.875 | 3/4″x10unc | 8 | 3.25 | 0.43 |

| 6 | 5.43 | 5.51 | 11.00 | 8.50 | 1.00 | 16.22 | 6.57 | 8.39 | 1.26 | – | 0.500 | 0.748 | 4.02 | 9.50 | 0.875 | 3/4″x10unc | 8 | 3.25 | 0.43 |

| 8 | 7.40 | 5.98 | 13.50 | 10.62 | 1.12 | 18.39 | 7.68 | 9.45 | 1.26 | – | 0.626 | 0.874 | 5.98 | 11.75 | 0.875 | 3/4″x10unc | 8 | 5.00 | 0.55 |

| 10 | 9.25 | 6.50 | 16.00 | 12.75 | 1.19 | 21.73 | 8.66 | 11.02 | 2.05 | – | 0.25×0.25 | 1.126 | 5.98 | 14.25 | 1.000 | 7/8″x9unc | 12 | 5.00 | 0.55 |

| 12 | 10.83 | 7.01 | 19.00 | 15.00 | 1.25 | 24.64 | 10.43 | 12.20 | 2.01 | – | 0.25×0.25 | 1.126 | 5.98 | 17.00 | 1.000 | 7/8″x9unc | 12 | 5.00 | 0.55 |

| 14 | 12.48 | 7.48 | 21.00 | 16.25 | 1.38 | 27.24 | 11.81 | 13.19 | 2.24 | – | 0.31×0.31 | 1.374 | 5.98 | 18.75 | 1.125 | 1″x8unc | 12 | 5.00 | 0.55 |

| 16 | 14.13 | 8.50 | 23.50 | 18.50 | 1.44 | 31.85 | 13.39 | 15.47 | 2.99 | – | 0.50×0.50 | 1.874 | 8.03 | 21.25 | 1.125 | 1″x8unc | 16 | 6.50 | 0.83 |

| 18 | 16.38 | 8.74 | 25.00 | 21.00 | 1.56 | 34.56 | 14.76 | 16.81 | 2.99 | – | 0.50×0.50 | 1.874 | 8.03 | 22.75 | 1.250 | 1 1/8″x8un | 16 | 6.50 | 0.83 |

| 20 | 18.39 | 9.02 | 27.50 | 23.00 | 1.69 | 36.46 | 15.75 | 17.72 | 2.99 | – | 0.50×0.50 | 2.126 | 8.03 | 25.00 | 1.250 | 1 1/8″x8un | 20 | 6.50 | 0.83 |

| 22 | 20.00 | 10.51 | 29.50 | 25.25 | 1.81 | 40.63 | 17.32 | 19.29 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 27.25 | 1.375 | 1 1/4″x8un | 20 | 10.00 | 0.75 |

| 24 | 21.57 | 10.51 | 32.00 | 27.25 | 1.88 | 43.59 | 18.70 | 20.87 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 29.50 | 1.375 | 1 1/4″x8un | 20 | 10.00 | 0.75 |

| 26 | 23.11 | 11.50 | 34.25 | 29.50 | 2.69 | 46.14 | 19.88 | 22.24 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 31.75 | 1.375 | 1 1/4″x8un | 24 | 10.00 | 0.75 |

| 28 | 25.12 | 11.50 | 36.50 | 31.50 | 2.81 | 49.49 | 21.85 | 23.62 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 34.00 | 1.375 | 1 1/4″x8un | 28 | 10.00 | 0.75 |

| 30 | 27.01 | 12.52 | 38.75 | 33.75 | 2.94 | 52.87 | 23.03 | 25.39 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 36.00 | 1.375 | 1 1/4″x8un | 28 | 10.00 | 0.75 |

| 32 | 28.94 | 12.52 | 41.75 | 36.00 | 3.19 | 55.04 | 24.21 | 26.38 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 38.50 | 1.625 | 1 1/2″x8un | 28 | 10.00 | 0.75 |

| 34 | 30.83 | 12.99 | 43.75 | 38.00 | 3.25 | 58.19 | 26.18 | 27.56 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 40.50 | 1.625 | 1 1/2″x8un | 32 | 10.00 | 0.75 |

| 36 | 33.03 | 12.99 | 46.00 | 40.25 | 3.56 | 59.57 | 26.38 | 28.74 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 42.75 | 1.625 | 1 1/2″x8un | 32 | 10.00 | 0.75 |

| 38 | 35.43 | 16.14 | 48.75 | 42.25 | 3.44 | 62.33 | 28.35 | 29.53 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 45.25 | 1.625 | 1 1/2″x8un | 32 | 10.00 | 0.75 |

| 40 | 37.32 | 16.14 | 50.75 | 44.25 | 3.56 | 70.59 | 29.84 | 30.12 | 5.91 | 4.72 | 1.10×0.63 | 3.933 | – | 47.25 | 1.625 | 1 1/2″x8un | 36 | 11.73 | 0.91 |

| 42 | 39.45 | 16.93 | 53.00 | 47.00 | 3.81 | 72.83 | 31.10 | 30.71 | 6.30 | 4.72 | 1.10×0.63 | 3.933 | – | 49.50 | 1.625 | 1 1/2″x8un | 36 | 11.73 | 0.91 |

| 48 | 44.37 | 18.50 | 59.50 | 53.50 | 4.25 | 81.69 | 35.43 | 34.65 | 6.30 | 5.31 | 1.26×0.71 | 4.720 | – | 56.00 | 1.625 | 1 1/2″x8un | 44 | 11.73 | 0.91 |

| Class 300 | |||||||||||||||||||

| Size(inch) | ød | L | O.D. | øg | t | H | H1 | H2 | H3 | H4 | K | øg | of | B.C.D. | øh | T | N | P.C.D. | øh2 |

| 4 | 3.74 | 5.04 | 10.00 | 6.19 | 1.25 | 13.15 | 4.88 | 7.01 | 1.26 | – | 0.500 | 0.748 | 4.02 | 7.88 | 0.875 | 3/4″x10unc | 8 | 3.25 | 0.43 |

| 5 | 4.65 | 5.51 | 11.00 | 7.31 | 1.38 | 14.41 | 5.55 | 7.60 | 1.26 | – | 0.500 | 0.748 | 4.02 | 9.25 | 0.875 | 3/4″x10unc | 8 | 3.25 | 0.43 |

| 6 | 5.39 | 5.51 | 12.50 | 8.50 | 1.44 | 16.85 | 6.93 | 8.66 | 1.26 | – | 0.500 | 0.748 | 4.02 | 10.62 | 0.875 | 3/4″x10unc | 12 | 3.25 | 0.43 |

| 8 | 7.32 | 5.98 | 15.00 | 10.62 | 1.62 | 20.71 | 8.46 | 10.24 | 2.01 | – | 0.25×0.25 | 1.126 | 5.98 | 13.00 | 1.000 | 7/8″x9unc | 12 | 5.00 | 0.55 |

| 10 | 9.06 | 6.50 | 17.50 | 12.75 | 1.88 | 22.96 | 9.53 | 11.42 | 2.01 | – | 0.25×0.25 | 1.126 | 5.98 | 15.25 | 1.125 | 1″x8unc | 16 | 5.00 | 0.55 |

| 12 | 10.79 | 7.01 | 20.50 | 15.00 | 2.00 | 25.56 | 10.75 | 12.80 | 2.01 | – | 0.31×0.31 | 1.374 | 5.98 | 17.75 | 1.250 | 1 1/8″x8un | 16 | 5.00 | 0.55 |

| 14 | 12.32 | 7.48 | 23.00 | 16.25 | 2.12 | 30.55 | 12.80 | 14.76 | 2.99 | – | 0.50×0.50 | 1.874 | 8.03 | 20.25 | 1.250 | 1 1/8″x8un | 20 | 6.50 | 0.83 |

| 16 | 14.02 | 8.50 | 25.50 | 18.50 | 2.25 | 34.09 | 14.37 | 16.73 | 2.99 | – | 0.50×0.50 | 2.122 | 8.03 | 22.50 | 1.375 | 1 1/4″x8un | 20 | 6.50 | 0.83 |

| 18 | 16.26 | 8.74 | 28.00 | 21.00 | 2.38 | 38.47 | 16.14 | 18.31 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 24.75 | 1.375 | 1 1/4″x8un | 24 | 10.00 | 0.75 |

| 20 | 18.35 | 9.02 | 30.50 | 23.00 | 2.50 | 41.62 | 17.72 | 19.88 | 4.02 | – | 0.75×0.50 | 2.555 | 11.42 | 27.00 | 1.375 | 1 1/4″x8un | 24 | 10.00 | 0.75 |

| 24 | 21.50 | 10.51 | 36.00 | 27.25 | 2.75 | 47.83 | 20.55 | 22.83 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 32.00 | 1.625 | 1 1/2″x8un | 24 | 10.00 | 0.75 |

| 26 | 23.70 | 11.50 | 38.25 | 29.50 | 3.13 | 51.30 | 22.05 | 24.80 | 4.45 | – | 0.87×0.55 | 3.146 | 12.99 | 34.50 | 1.750 | 1 5/8″x8un | 28 | 10.00 | 0.75 |

| 28 | 25.43 | 11.50 | 40.75 | 31.50 | 3.38 | 60.24 | 24.02 | 25.20 | 6.30 | 4.72 | 1.10×0.63 | 3.933 | – | 37.00 | 1.750 | 1 5/8″x8un | 28 | 11.73 | 0.91 |

| 30 | 27.17 | 12.52 | 43.00 | 33.75 | 3.63 | 62.59 | 25.98 | 25.59 | 6.30 | 4.72 | 1.10×0.63 | 3.933 | – | 39.25 | 1.875 | 1 3/4″x8un | 28 | 11.73 | 0.91 |

| 32 | 29.53 | 12.52 | 45.25 | 36.00 | 3.88 | 65.35 | 27.56 | 26.77 | 6.30 | 4.72 | 1.10×0.63 | 3.933 | – | 41.50 | 2.000 | 1 7/8″x8un | 28 | 11.73 | 0.91 |

| 36 | 33.46 | 12.99 | 50.00 | 40.25 | 4.13 | 71.25 | 29.72 | 29.92 | 6.30 | 5.31 | 1.26×0.71 | 4.720 | – | 46.00 | 2.125 | 2″x8un | 32 | 11.73 | 0.91 |

| 38 | 35.28 | 16.14 | 46.00 | 40.50 | 4.25 | 70.27 | 29.13 | 29.53 | 6.30 | 5.31 | 1.26×0.71 | 4.720 | – | 43.00 | 1.625 | 1 1/2″x8un | 32 | 11.73 | 0.91 |

| 40 | 36.77 | 16.22 | 48.75 | 42.75 | 4.50 | 73.15 | 29.84 | 30.71 | 6.69 | 5.91 | 1.42×0.79 | 5.508 | – | 45.50 | 1.750 | 1 5/8″x8un | 32 | 14.02 | 1.30 |

| 48 | 43.07 | 18.50 | 57.75 | 51.25 | 5.25 | 86.21 | 34.84 | 36.61 | 7.87 | 6.89 | 1.77×098 | 7.039 | – | 54.00 | 2.000 | 1 7/8″x8un | 32 | 15.98 | 1.54 |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.