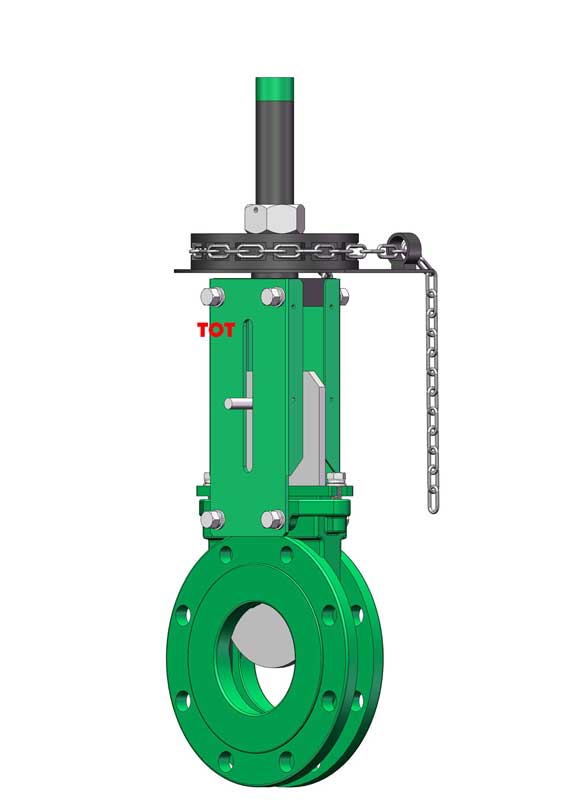

Chainwheel Operated Knife Gate Valve

When you need reliable valve operation in high-mounted or hard-to-reach installations, a chainwheel operated knife gate valve provides the perfect solution. This heavy-duty stainless steel chainwheel knife gate valve is specifically designed for elevated applications — whether you’re controlling slurry lines, pulp systems, or corrosive fluid pipelines mounted overhead or in confined spaces. The integrated chainwheel operator allows safe, convenient ground-level operation while maintaining the rugged performance of our proven knife gate design. With robust chain drive mechanism and corrosion-resistant construction, it ensures reliable control in challenging industrial environments.

Ready to improve accessibility in your elevated flow control systems? Contact us today for a chainwheel-operated solution designed for your specific installation requirements. Let TOT Valve bring control within reach.

The TOT Valve You Can Depend On – Ground Level Control for Elevated Applications

When your process involves elevated pipelines, overhead installations, or confined space applications handling slurry, pulp, abrasive fluids, or corrosive chemicals, you need the accessibility of our chainwheel operated knife gate valve. With its integrated chainwheel drive system, this knife gate valve provides safe ground-level operation, precise control, and mechanical advantage — all while delivering the reliable shut-off performance you expect from TOT Valve.

The chainwheel operation eliminates the need for ladders, platforms, or aerial access equipment, significantly improving operator safety and reducing maintenance costs in elevated installations.

Why Chainwheel Operated Knife Gate Valve Works for You?

- Corrosion-resistant stainless steel (SS304/316/316L) ensures long-term performance in harsh environments.

- Integrated chainwheel drive provides safe ground-level operation for elevated installations.

- Mechanical advantage system reduces operating effort for large valve sizes.

- Knife-edge gate cuts through tough media including fibrous materials, thick slurry, and settled solids.

- Heavy-duty chain mechanism designed for continuous operation and extended service life.

- Position indication shows valve open/close status from ground level.

- Weather-resistant construction suitable for outdoor and exposed installations.

- Multiple mounting options – lug, wafer, or flanged body styles available.

- Lockable operation security features prevent unauthorized valve operation.

- Low maintenance design with replaceable chain, sprockets, and wear components.

- Fail-safe positioning maintains last position in case of chain breakage.

Chainwheel Knife Gate Valve Main Technical Specifications & Performance

Ground-Level Operated, Heavy-Duty Chain Drive, Knife Gate Valve

| Specification | Details |

|---|---|

| Design & Manufacturing Standard | MSS SP-81, API 6D |

| Size Range | DN80 to DN1200 mm; NPS 3″-48″ (Customized to Your Request) |

| Pressure Ratings | PN10, PN16, ANSI 150Psi, 5K/10K, etc. |

| Working Pressure Classification | DN80–DN250: 10Bar; DN300–DN450: 7Bar; DN500–DN600: 4Bar; DN700–DN1200: 2Bar |

| Face-to-Face Standard | MSS SP-81, Short/Long Pattern Available |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Chain Drive Standard | ISO 606, ANSI B29.1 |

| Inspection & Testing Standard | MSS SP-81, API 598 |

| Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Operating Height | Up to 6 meters (20 feet) standard, extended heights available |

| Chain Material | Stainless steel 316, galvanized carbon steel, or special alloys |

| Temperature–Pressure Rating Standards | GB/T12224–2007, ASME B16.34–2009, ISO7005–1 |

| Applications | Water Treatment Plants, Pulp & Paper Mills, Mining Operations, Chemical Plants, Power Stations, Municipal Systems, Overhead Pipeline Systems |

| Environmental Rating | IP65 (weatherproof), suitable for outdoor installations |

Chainwheel Knife Gate Valve Main Components and Materials

| Part Name | Material Options | ||

|---|---|---|---|

| WCB | CF8 | CF8M | |

| Valve Body | WCB | CF8 | CF8M |

| Gate | 304 | 316 | 316L |

| Seat | STL or EPDM | STL or EPDM | STL or EPDM |

| O-ring | NBR | NBR | EPDM |

| Bonnet | WCB | CF8 | CF8M |

| Packing | PTFE | PTFE | PTFE |

| Yoke | Q235 | 304 | 316 |

| Stem | 2Cr13 | 316 | 316L |

| Stem Nut | Bronze | Bronze | Bronze |

| Chain Sprocket | Cast Steel | 304 SS | 316 SS |

| Drive Chain | Galvanized Steel | 316 SS | 316 SS |

| Chainwheel | Cast Iron/Steel | Cast Steel | Cast Steel |

| Chain Guide | Steel | 304 SS | 316 SS |

| Position Indicator | Aluminum | Aluminum | Aluminum |

| Weather Cover | Steel/Aluminum | Aluminum | Aluminum |

| Mounting Bracket | Steel | 304 SS | 316 SS |

| Fasteners | A193-B7 | A4-70 | A4-80 |

TOT Valve Tailored for Your Elevated Systems – Custom Chain Drive Options

You can customize this chainwheel valve for your specific installation requirements:

Chain Length: Standard 3-6 meters, extended lengths up to 15 meters available

Chain Material: Galvanized steel, 316 stainless steel, or special corrosion-resistant alloys

Wheel Size: Multiple chainwheel diameters for optimal mechanical advantage

Position Indication: Visual indicators, limit switches, or transmitter feedback

Weather Protection: Stainless steel covers, aluminum housings, or marine-grade coatings

Security Features: Padlock provisions, removable chainwheel, or keyed operation

Special Mounting: Custom brackets for specific structural configurations

Automation Ready: Provision for electric or pneumatic actuator override

Chainwheel Knife Gate Valve Dimensions

TOT valve can provide you with various sizes of chainwheel operated knife gate valve. We have listed some chainwheel knife gate valve sizes for PN16 for your reference.

If you don’t have the chainwheel knife gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | Chain Length (m) | Wheel Dia. (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | NPS(in) | |||||||||

| 80 | 3″ | 51 | 175 | 106 | 121 | 168 | 85 | 200 | 478 | 3.0 |

| 100 | 4″ | 51 | 163 | 106 | 138 | 192 | 85 | 200 | 545 | 3.0 |

| 125 | 5″ | 57 | 192 | 120 | 160 | 215 | 87 | 250 | 630 | 3.5 |

| 150 | 6″ | 57 | 216 | 130 | 185 | 245 | 87 | 280 | 705 | 3.5 |

| 200 | 8″ | 70 | 271 | 130 | 235 | 302 | 105 | 300 | 850 | 4.0 |

| 250 | 10″ | 70 | 335 | 140 | 300 | 355 | 105 | 350 | 1065 | 4.0 |

| 300 | 12″ | 76 | 381 | 160 | 350 | 401 | 105 | 400 | 1200 | 4.5 |

| 350 | 14″ | 76 | 436 | 180 | 400 | 465 | 117 | 450 | 1375 | 4.5 |

| 400 | 16″ | 89 | 505 | 180 | 455 | 511 | 117 | 450 | 1525 | 5.0 |

| 450 | 18″ | 89 | 568 | 200 | 510 | 578 | 130 | 500 | 1720 | 5.0 |

| 500 | 20″ | 102 | 632 | 220 | 565 | 645 | 130 | 550 | 1915 | 5.5 |

Typical Applications & Installation Scenarios

Water Treatment Plants: Overhead sludge lines, elevated chemical feed systems, clarifier mechanisms

Pulp & Paper Mills: Stock preparation systems, bleach plant piping, elevated process lines

Mining Operations: Tailings pipelines, thickener overflow lines, elevated concentrate systems

Power Plants: Ash handling systems, cooling water lines, elevated utility piping

Chemical Processing: Reactor overflow systems, elevated transfer lines, safety relief systems

Municipal Systems: Water distribution, elevated storage tank connections, pump station isolation

Chain Drive System Features

Mechanical Advantage: Gear reduction provides easy operation even for large valves

Durable Construction: Heavy-duty roller chain rated for continuous operation

Weather Resistance: Galvanized or stainless steel components resist corrosion

Safety Features: Chain guards prevent entanglement and protect operators

Position Feedback: Clear visual indication of valve position from ground level

Maintenance Access: Chain tensioning and lubrication points easily accessible

Installation & Safety Advantages

Operator Safety: Eliminates need for elevated platforms or ladder access

Reduced Maintenance Costs: Ground-level operation reduces service time and risk

Improved Accessibility: Operation possible even in confined or congested areas

Emergency Operation: Manual override capability ensures valve operation during power outages

Flexible Installation: Chain can be routed around obstructions to convenient operating location

Security: Chainwheel can be removed or locked to prevent unauthorized operation

Quality Assurance & Testing

Every TOT chainwheel operated knife gate valve undergoes comprehensive testing:

- Hydrostatic pressure testing at 1.5x working pressure

- Chain drive system testing for smooth operation and mechanical advantage

- Cycling tests to verify reliable operation over service life

- Environmental testing for outdoor and harsh environment suitability

- Position indication accuracy verification

- Chain tension and alignment optimization

Maintenance Support & Service

Comprehensive Documentation: Installation, operation, and maintenance manuals provided

Spare Parts Availability: Complete inventory of chain drive components and valve parts

Field Service: On-site installation, commissioning, and maintenance support available

Training Programs: Operator and maintenance training for safe, efficient operation

Technical Support: 24/7 engineering support for troubleshooting and optimization

Contact TOT Valve today for technical consultation and competitive quotation on your chainwheel operated knife gate valve requirements for elevated and hard-to-reach applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.