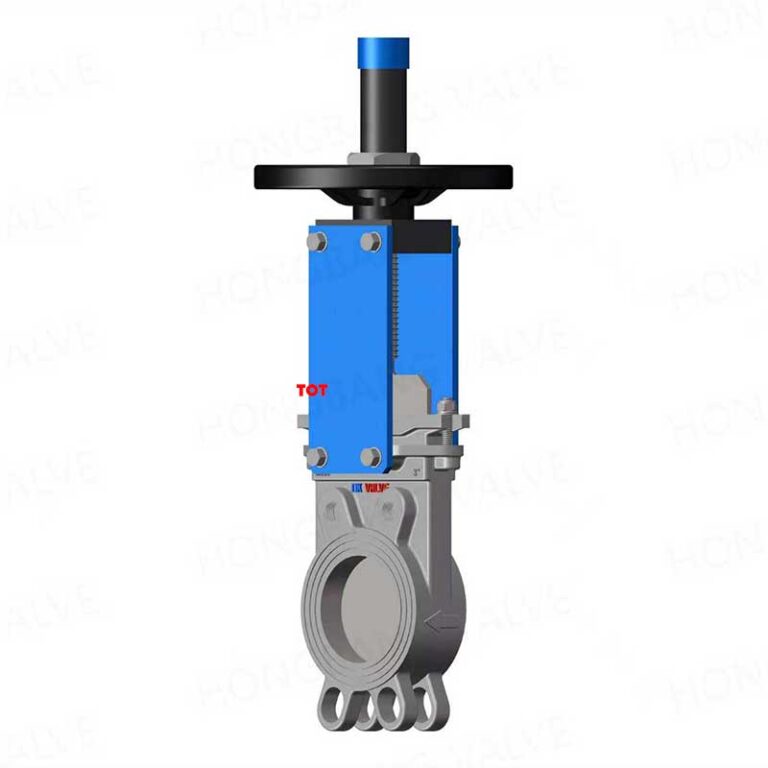

DN150 Knife Gate Valve (6 Inch)

The DN150 Knife Gate Valve is a robust industrial valve engineered with a sharp-edged gate design that efficiently cuts through challenging media including fibrous materials, slurries, and viscous fluids. This 6-inch valve delivers exceptional shut-off performance and reliable sealing, making it the preferred choice for demanding applications in pulp & paper mills, wastewater treatment plants, mining operations, and chemical processing facilities.

Technical Specifications

Basic Parameters

- Nominal Diameter: DN150 (6 inches)

- Connection Type: Flanged, Wafer, Lug style, Welded

- Structure: Rising stem, Non-rising stem

- Actuation: Manual, Pneumatic, Electric, Hydraulic

- Flow Direction: Bidirectional sealing capability

Pressure Ratings

- Nominal Pressure: PN6, PN10, PN16, PN25, PN40

- Working Pressure: 0.6-4.0 MPa (87-580 PSI)

- Test Pressure: Per API 598, ISO 5208, EN 12266 standards

Temperature Range

- Operating Temperature: -29°C to +232°C (-20°F to +450°F)

- Extended Temperature: Up to 400°C with special materials

- Media Temperature: Varies by seal and body material selection

Dimensional Data

- Face-to-Face: Per ASME B16.10, EN 558-1

- Flange Drilling: ASME B16.5, EN 1092-1, JIS B2220

- Weight: Approximately 45-85 kg (depending on materials and actuation)

Key Features

Advanced Design Benefits

- Precision Knife-Edge Gate: Hardened cutting edge shears through tough fibrous media

- Full Bore Design: Unobstructed flow passage ensures minimal pressure loss

- Bidirectional Service: Equal sealing performance in both flow directions

- Space-Efficient: Compact face-to-face dimensions for tight installations

- Self-Cleaning Action: Gate movement clears debris from sealing surfaces

Performance Advantages

- Superior Cutting Power: Handles paper pulp, textile fibers, and stringy materials

- Tight Shut-Off: Bubble-tight sealing per API 598 standards

- Low Operating Torque: Efficient design reduces actuator requirements

- Extended Service Life: Robust construction withstands abrasive conditions

- Easy Maintenance: Replaceable seats and packing for field serviceability

Material Specifications

Body Construction

- Cast Iron: ASTM A126 Class B, EN-GJL-250

- Ductile Iron: ASTM A395, EN-GJS-400-18-LT

- Carbon Steel: ASTM A216 WCB, A352 LCB (low temperature)

- Stainless Steel:

- CF8 (304): General corrosion resistance

- CF8M (316): Enhanced chemical resistance

- CF3M (316L): Low carbon for welding applications

- Duplex 2205: High strength and corrosion resistance

Gate Materials

- Stainless Steel: 304, 316, 316L, 17-4PH, Duplex 2205

- Tool Steel: Hardened for abrasive service

- Hastelloy: Extreme corrosion resistance

- Surface Treatments: Hard chrome plating, ceramic coating, stellite facing

Sealing Components

- Elastomeric Seals:

- NBR (Buna-N): -40°C to +120°C, oil/water service

- EPDM: -45°C to +150°C, steam/ozone resistance

- Viton (FKM): -15°C to +200°C, chemical resistance

- HNBR: Enhanced temperature and chemical resistance

- Metal Seats: Stainless steel, Stellite for high-temperature service

- PTFE: Chemical inertness, -200°C to +260°C

Applications & Industries

Primary Applications

- Pulp & Paper Industry:

- Stock preparation systems

- Bleaching plant operations

- White water and filtrate handling

- Broke and reject processing

- Water & Wastewater Treatment:

- Primary and secondary sludge handling

- Scum and grit removal systems

- Digester feed and withdrawal

- Polymer and chemical feed systems

- Mining & Minerals:

- Ore slurry transport

- Tailings pond operations

- Concentrate thickening

- Flotation cell isolation

- Food & Beverage:

- Fruit and vegetable processing

- Sugar refining operations

- Brewery and distillery applications

- Dairy processing systems

- Chemical & Petrochemical:

- Catalyst slurry handling

- Polymer and resin processing

- Crystallizer operations

- Reactor isolation

Service Media

- Paper pulp and stock (up to 6% consistency)

- Municipal and industrial sludge

- Mining slurries and tailings

- Food products and by-products

- Chemical slurries and suspensions

- Abrasive and erosive media

Design & Manufacturing Standards

International Standards Compliance

- Design Standards: API 6A, ASME B16.34, EN 19434

- Testing Standards: API 598, ISO 5208, EN 12266-1

- Face-to-Face Dimensions: ASME B16.10, EN 558-1, ISO 5752

- Flange Standards: ASME B16.5, EN 1092-1, JIS B2220

- Material Standards: ASTM, EN, JIS specifications

Quality Certifications

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management

- OHSAS 18001 Occupational Health & Safety

- CE Marking (PED 2014/68/EU where applicable)

- API 6A PSL 1-4 Certification

- SIL 2/3 Functional Safety (actuated versions)

Installation & Maintenance

Installation Guidelines

- Pre-Installation Inspection:

- Verify valve specification against P&ID requirements

- Check for shipping damage and foreign material

- Confirm proper storage and handling procedures

- Installation Best Practices:

- Install with valve in closed position

- Ensure pipeline is properly supported

- Verify flange bolt torque values

- Maintain minimum clearances for operation

- Consider thermal expansion effects

Maintenance Procedures

- Routine Maintenance:

- Monthly operation cycling (if feasible)

- Quarterly packing adjustment if needed

- Semi-annual complete functional testing

- Annual internal inspection (where possible)

- Preventive Maintenance:

- Seat and gate wear monitoring

- Actuator lubrication and calibration

- Stem packing replacement schedule

- Bolting torque verification

Actuator Options

Manual Operation

- Handwheel: Standard 20-24 inch diameter for DN150

- Chainwheel: For elevated installations

- Lever: Quick quarter-turn operation where applicable

- Gearbox: Reduction gearing for high-pressure applications

Automated Actuation

- Pneumatic Actuators:

- Spring return (fail-safe operation)

- Double acting (precise positioning)

- Scotch yoke or rack & pinion design

- Stainless steel construction available

- Electric Actuators:

- Multi-turn design for gate valves

- Integral or remote control options

- Position feedback and diagnostics

- Explosion-proof ratings available

- Hydraulic Actuators:

- High force capability

- Precise position control

- Fast operation speeds

- Suitable for remote locations

Ordering Information

Complete Model Designation

DN150-KGV-[Pressure]-[Body Material]-[Gate Material]-[Seat Material]-[Actuation]-[Connection]

Example: DN150-KGV-PN16-CF8M-316L-EPDM-PNEU-RF150

Required Specifications

- Service Conditions:

- Media type and concentration

- Operating temperature and pressure

- Flow rates and velocities

- Cycling frequency requirements

- Material Requirements:

- Body and bonnet materials

- Internal trim specifications

- Seat and seal materials

- Special coatings or treatments

- Actuation & Accessories:

- Manual or automated operation

- Control signal requirements (4-20mA, digital, etc.)

- Position indication needs

- Emergency operation requirements

Factory Options

- Pneumatic or electric actuation packages

- Position transmitters and limit switches

- Special testing and inspection

- Custom materials and coatings

- Extended warranties and service contracts

Quality Assurance & Testing

Standard Factory Testing

- Hydrostatic shell test: 1.5 × working pressure

- Seat leakage test per API 598 (Class IV-VI available)

- Operational torque verification

- Dimensional and visual inspection

- Material certification review

Enhanced Testing Options

- Witnessed testing by third-party inspectors

- Extended duration testing

- Special media compatibility testing

- Accelerated life cycle testing

- Custom test procedures per customer specifications

Documentation Package

- Material test certificates per EN 10204 3.1/3.2

- Dimensional inspection reports

- Test certificates and data sheets

- Operation and maintenance manuals

- Spare parts recommendations

- Warranty certificates

Engineering Support: Our technical team provides comprehensive application engineering, custom design solutions, and ongoing technical support throughout the valve lifecycle.

Global Service Network: Factory-trained service technicians, genuine spare parts inventory, and emergency support services available worldwide.

For technical consultation, detailed quotations, or application-specific information, contact our engineering sales team.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.