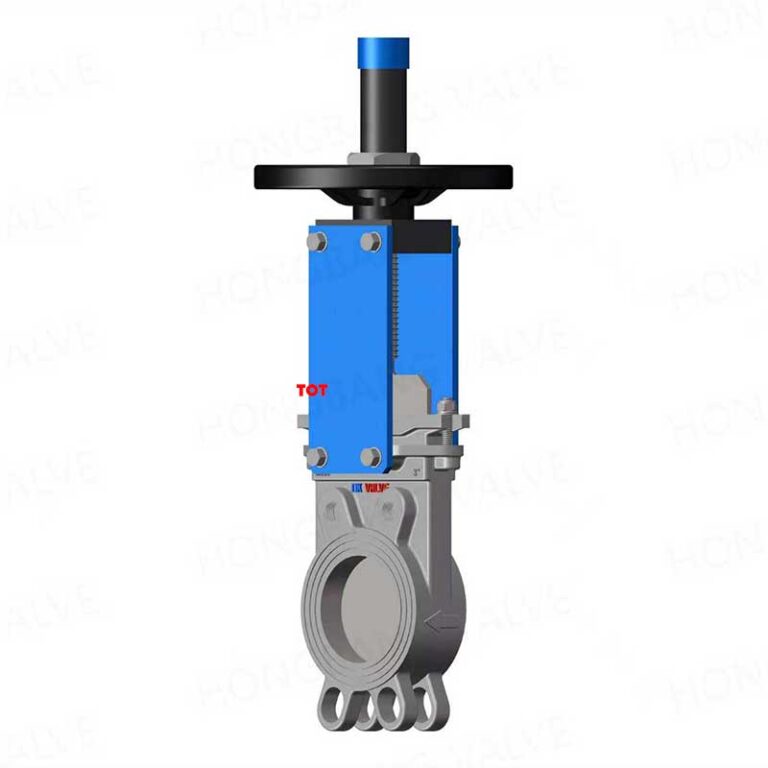

DN250 Knife Gate Valve (10 Inch)

The DN250 Knife Gate Valve stands as the flagship solution for 10-inch industrial pipeline applications, representing the apex of heavy-duty valve engineering. This premium valve features an ultra-precision knife-edge gate system designed to handle the most demanding service conditions in large-scale industrial operations. Built for continuous duty in major pulp mills, municipal treatment plants, mining complexes, and industrial process facilities, the DN250 delivers unmatched reliability, performance, and operational efficiency in challenging environments.

Technical Specifications

Core Parameters

- Nominal Diameter: DN250 (10 inches)

- Full Bore Diameter: 250mm (9.84″) unrestricted flow passage

- Connection Standards: ANSI/ASME B16.5/B16.47, DIN/EN 1092, API 6A Type 6BX

- Structural Options: Rising stem, Non-rising stem, Enclosed bonnet, Bellows seal

- Actuation Capability: Manual, Pneumatic, Electric, Electrohydraulic, Integrated smart systems

- Flow Configuration: Bidirectional service with equal upstream/downstream performance

Pressure Performance

- ANSI Pressure Class: 150, 300, 600, 900, 1500, 2500 (RTJ available)

- DIN/EN Pressure Rating: PN6, PN10, PN16, PN25, PN40, PN63, PN100

- Working Pressure Range: 1.0-16.0 MPa (145-2320 PSI)

- Hydrostatic Test Pressure: 1.5 × working pressure per API 598

- Maximum Design Pressure: Up to 25.0 MPa (3625 PSI) with special engineering

Thermal Performance

- Standard Temperature Range: -46°C to +260°C (-50°F to +500°F)

- Extended Temperature Service: -196°C to +650°C (-321°F to +1200°F)

- Cryogenic Applications: LNG, LN2, liquid oxygen compatible designs

- High Temperature Service: Molten sulfur, hot bitumen, thermal oil applications

- Thermal Shock Resistance: Rapid temperature cycling capability

Mechanical Specifications

- Face-to-Face Dimensions: ASME B16.10, EN 558-1, API 6D, AWWA C500

- Overall Height: 850-1400mm (varies by configuration and actuation)

- Flange Drilling Patterns: ASME B16.5/47, EN 1092-1/2, API 6A, JIS B2220

- Operating Weight: 140-350 kg (depending on materials and actuator package)

- Maximum Operating Torque: 2000-8000 Nm (varies by size and pressure)

Revolutionary Design Engineering

Advanced Cutting Technology

- Ultra-Sharp Knife Edge: CNC-machined premium tool steel with 25° optimized bevel

- Self-Sharpening Action: Gate geometry maintains cutting efficiency over service life

- Debris Rejection System: Integrated wiper seals prevent contamination buildup

- Hydrodynamic Optimization: CFD-engineered body geometry minimizes turbulence

- Cavitation Resistance: Special trim design prevents cavitation damage

Superior Sealing Technology

- Triple Sealing System: Primary seat, secondary backup, and stem packing

- Adaptive Seat Technology: Self-compensating seats maintain seal integrity

- Zero Emission Design: Fugitive emission compliance per ISO 15848 Class A

- Pressure Energized Sealing: Upstream pressure enhances sealing force

- Emergency Sealing: Injection-moldable emergency seal capability

Intelligent Engineering Features

- Smart Diagnostics: Integrated sensors for real-time performance monitoring

- Predictive Analytics: AI-powered maintenance scheduling and fault prediction

- Digital Twin Ready: Full parametric modeling for virtual commissioning

- Cyber Security: Industrial IoT security per IEC 62443-4-2 standards

- Remote Monitoring: Wireless connectivity with cloud-based analytics

Extreme Service Adaptability

- Anti-Cavitation Trim: Staged pressure reduction for high ΔP applications

- Abrasion Protection: Replaceable wear plates and hardened surfaces

- Corrosion Barrier Systems: Advanced coating and lining technologies

- Thermal Isolation: Insulation and heat dissipation design features

- Vibration Dampening: Resonance frequency optimization and isolation

Premium Material Engineering

Advanced Body Construction

- High-Grade Cast Iron: ASTM A126 Class C, A48 Class 40, Ni-Resist Type 2

- Superior Ductile Iron: ASTM A395-18, EN-GJS-500-7, specialized nodular irons

- Carbon Steel Alloys: A216 WCB, A352 LCB/LCC, A217 WC1/WC6/WC9

- Stainless Steel Portfolio:

- CF8 (304): Standard corrosion resistance, cost-effective

- CF8M (316): Enhanced chemical resistance, marine applications

- CF3 (304L): Low-carbon welding grade, pharmaceutical applications

- CF3M (316L): Superior corrosion resistance, food-grade service

- CN7M (Alloy 20): Exceptional chemical resistance, sulfuric acid service

- CD4MCu (Super Duplex): Ultra-high strength and corrosion resistance

- CK3MCuN (Super Duplex 2507): Maximum performance in severe environments

Specialized Gate Materials

- Premium Stainless Grades: 304, 316, 316L, 17-4PH, 15-5PH, Custom 450

- Super Duplex Alloys: 2205, 2507, Zeron 100, SAF 2906

- Nickel-Based Superalloys:

- Hastelloy C-276: Universal chemical resistance

- Inconel 625/686: High-temperature strength and corrosion resistance

- Monel 400/K500: Seawater and hydrofluoric acid service

- Exotic Materials: Titanium Grade 2/7, Zirconium 702, Tantalum

Advanced Surface Technologies

- Hard Chrome Plating: 62-68 HRC surface hardness, 0.05-0.15mm thickness

- Ceramic Coatings: Al2O3, Cr2O3, TiN for extreme abrasion resistance

- Thermal Spray Applications: Tungsten carbide, chromium carbide overlays

- PVD/CVD Coatings: Diamond-like carbon, titanium nitride surface treatments

- Laser Cladding: Stellite 6/12, Inconel 625 hardfacing applications

Comprehensive Sealing Solutions

- High-Performance Elastomers:

- NBR (Nitrile): -40°C to +120°C, hydrocarbon compatibility

- HNBR: -30°C to +150°C, enhanced oil and heat resistance

- EPDM: -45°C to +150°C, steam, ozone, and weather resistance

- FKM (Viton): -15°C to +200°C, broad chemical compatibility

- FFKM (Kalrez): -15°C to +327°C, universal chemical resistance

- FEPM (Aflas): -10°C to +230°C, steam and amine resistance

- Perfluoroelastomer: -25°C to +250°C, extreme chemical inertness

- Metal Sealing Systems:

- 316/316L laminated construction for high-temperature service

- Stellite 6/12 hard-faced seats for maximum abrasion resistance

- Inconel X-750 spring-loaded designs for thermal cycling

- Custom alloy combinations for specialized chemical service

Comprehensive Industrial Applications

Pulp & Paper Manufacturing

- Fiber Line Operations:

- High-consistency pulp handling (up to 12% consistency)

- Brownstock washing and screening systems

- Oxygen delignification and bleaching sequences

- Reject and sludge handling systems

- Stock preparation and cleaning operations

- Chemical Recovery Systems:

- Black liquor concentration and recovery

- Green liquor clarification and filtration

- White liquor preparation and causticizing

- Lime mud washing and reburning systems

- Tall oil recovery and turpentine handling

- Paper Machine Applications:

- Headbox consistency regulation and dilution

- Wire pit and saveall operations

- Broke handling and repulping systems

- Coating kitchen and size press applications

- Water treatment and clarification systems

Municipal & Industrial Water Treatment

- Primary Treatment Systems:

- Raw water intake and screening operations

- Primary clarifier sludge withdrawal

- Grit removal and classification systems

- Scum handling and skimming operations

- Chemical coagulation and flocculation

- Secondary & Advanced Treatment:

- Activated sludge process control

- Secondary clarifier operations

- Biological nutrient removal systems

- Membrane bioreactor (MBR) applications

- Tertiary filtration and disinfection

- Sludge Processing Operations:

- Primary and secondary sludge thickening

- Anaerobic digestion feed and withdrawal

- Sludge dewatering and conditioning

- Biogas handling and processing systems

- Ash and residue management

Mining & Metallurgical Processing

- Mineral Processing Operations:

- Ore grinding and classification circuits

- Flotation cell feed and discharge systems

- Concentrate and tailing thickener operations

- Hydrometallurgical leaching circuits

- Solvent extraction and electrowinning

- Coal Processing Applications:

- Heavy media separation systems

- Coal flotation and dewatering operations

- Fine coal recovery and cleaning circuits

- Refuse and tailing management systems

- Coal preparation plant water circuits

- Tailings Management:

- Tailings pipeline transport systems

- Thickener underflow and overflow handling

- Paste and high-density tailings systems

- Water recovery and recycling operations

- Environmental compliance and monitoring

Chemical & Petrochemical Industries

- Process Applications:

- Reactor feed and discharge systems

- Catalyst slurry handling and regeneration

- Crystallization and precipitation operations

- Separation and purification processes

- Polymer and resin manufacturing

- Waste Treatment Systems:

- Chemical waste neutralization and treatment

- Hazardous material handling and processing

- Incineration and thermal treatment systems

- Scrubber and emission control systems

- Residue and byproduct management

Power Generation & Energy

- Fossil Fuel Plants:

- Coal handling and preparation systems

- Ash handling and removal operations

- Flue gas desulfurization (FGD) systems

- Cooling water treatment and conditioning

- Waste heat recovery systems

- Renewable Energy Applications:

- Biomass fuel handling and processing

- Biogas production and purification

- Geothermal brine and steam handling

- Solar thermal system operations

- Energy storage system applications

International Standards & Certifications

Primary Design Standards

- API Standards: API 6A (wellhead equipment), API 6D (pipeline valves)

- ASME Codes: ASME B16.34 (valve design), ASME B31.1/B31.3 (piping)

- European Standards: EN 19434 (industrial valves), EN 12266 (testing)

- ISO Standards: ISO 14313 (pipeline valves), ISO 5208 (pressure testing)

- Industry Specific: AWWA C500 (gate valves), MSS SP-81 (knife gate valves)

Testing & Quality Protocols

- Pressure Testing: API 598, ISO 5208, EN 12266-1, ASME B16.34

- Leakage Classification: API 598 Class II-VI, ISO 5208 Rate A-CC

- Fire Safety Testing: API 607, ISO 10497, BS 6755 Part 2

- Fugitive Emissions: ISO 15848, API 622/624, TA-Luft Class A/AH

- Functional Testing: MSS SP-81, AWWA C500, custom protocols

Quality Management & Certifications

- ISO 9001:2015: Comprehensive quality management system

- ISO 14001:2015: Environmental management system certification

- ISO 45001:2018: Occupational health and safety management

- API Q1 10th Edition: Quality management for petroleum industry

- ASME Section VIII: Pressure vessel design and NB stamp authorization

- Nuclear QA: ASME NQA-1, 10CFR50 Appendix B (where applicable)

Product Compliance Certifications

- CE Marking: PED 2014/68/EU compliance for European markets

- API 6A Monogram: PSL 1-4 product specification level certification

- CRN Registration: Canadian Registration Numbers for pressure service

- SIL Certification: IEC 61508/61511 functional safety up to SIL 3

- ATEX Certification: 2014/34/EU explosive atmosphere compliance

- Marine Classification: ABS, DNV-GL, Lloyd’s Register approvals

Advanced Automation & Control

Pneumatic Actuation Systems

- High-Performance Spring Return:

- Fail-safe close or open configurations available

- Compact scotch yoke design with 180° rotation capability

- Operating pressures from 3-10 bar (43-145 PSI)

- Response times: 3-8 seconds depending on configuration

- Corrosion-resistant construction with marine-grade coatings

- Precision Double-Acting Systems:

- Modulating control capability with 4-20mA positioning

- Rack and pinion or scotch yoke mechanisms available

- Stainless steel construction for harsh chemical environments

- Integrated limit switches and position transmitters

- Emergency pneumatic supply and manual override capability

- Advanced Pneumatic Packages:

- Integrated solenoid valve manifolds and filter regulators

- Pneumatic partial stroke testing (PST) capability

- Intelligent pneumatic positioners with HART communication

- Explosion-proof and weatherproof enclosure options

- Remote monitoring and diagnostic capabilities

Electric Actuation Technology

- High-Torque Multi-Turn Actuators:

- Output torques from 2,000 to 50,000 Nm available

- Voltage options: 120V, 240V, 480V, 600V AC or 24V/48V DC

- Integral or remote NEMA 4X/IP67 control enclosures

- Manual handwheel override with declutching mechanism

- Motor protection: overload, overheat, phase loss protection

- Intelligent Electric Systems:

- Digital positioning with sub-degree accuracy

- Multiple communication protocols: 4-20mA, HART, Modbus, Profibus

- Integrated valve controller with PID control capability

- Asset management features and predictive maintenance

- Cybersecurity features per IEC 62443 standards

- Smart Actuator Technology:

- Wireless communication capability (WirelessHART, LoRaWAN)

- Edge computing and local analytics processing

- Machine learning algorithms for performance optimization

- Digital twin integration for virtual commissioning

- Blockchain-based security and traceability features

Hydraulic & Electrohydraulic Systems

- Custom Hydraulic Cylinders:

- Force capabilities up to 500,000 N (112,000 lbf)

- Operating pressures up to 350 bar (5,000 PSI)

- Stroke lengths customized to application requirements

- Cushioning and flow control for smooth operation

- Corrosion-resistant construction with hard chrome plating

- Electrohydraulic Control Systems:

- Servo valve control for precise positioning (±0.1% accuracy)

- Integrated HPU (hydraulic power unit) packages available

- Emergency accumulator systems for fail-safe operation

- Remote control capability with fiber optic communication

- Condition monitoring with oil analysis and filtration systems

Engineering & Installation Services

Advanced Engineering Support

- Computational Fluid Dynamics (CFD): Flow analysis and optimization studies

- Finite Element Analysis (FEA): Stress analysis and structural optimization

- Vibration Analysis: Modal analysis and resonance frequency studies

- Thermal Analysis: Heat transfer and thermal stress calculations

- Fatigue Analysis: Cycle life prediction and failure mode analysis

Custom Design Capabilities

- Application-Specific Engineering: Tailored solutions for unique requirements

- Pilot Testing: Laboratory and field testing of critical applications

- Prototype Development: Rapid prototyping and proof-of-concept validation

- Reverse Engineering: Replacement of obsolete valve designs

- Upgrade Engineering: Modernization of existing valve installations

Project Management Services

- Turnkey Project Delivery: Complete responsibility from design to commissioning

- Schedule Optimization: Critical path analysis and timeline management

- Quality Assurance: Third-party inspection and witness testing

- Logistics Coordination: Global shipping and customs clearance

- Installation Supervision: Factory technician oversight and training

Commissioning & Startup Support

- Pre-Commissioning Services: System checkout and functional verification

- Performance Testing: Comprehensive acceptance testing protocols

- Operator Training: Hands-on training programs for plant personnel

- Documentation Package: Complete O&M manuals and spare parts lists

- Warranty Activation: Performance guarantee validation and documentation

Comprehensive Maintenance Solutions

Predictive Maintenance Technologies

- Vibration Monitoring: Accelerometer and velocity sensors for bearing analysis

- Acoustic Emission: Ultrasonic monitoring for seat and packing leakage

- Thermographic Analysis: Infrared imaging for electrical and mechanical issues

- Motor Current Signature Analysis: Electric actuator performance trending

- Oil Analysis Programs: Hydraulic system condition monitoring

- Wireless Sensor Networks: IoT-based continuous monitoring systems

Preventive Maintenance Programs

- Customized PM Schedules: Based on service conditions and criticality

- Condition-Based Maintenance: Maintenance triggered by actual equipment condition

- Reliability-Centered Maintenance: Optimized maintenance strategies

- Spare Parts Management: Inventory optimization and availability guarantees

- Training Programs: Comprehensive maintenance technician certification

Advanced Repair Services

- Factory Authorized Repair Centers: Global network of certified service facilities

- Mobile Repair Services: On-site repair capabilities for large valves

- Remanufacturing Programs: Complete valve restoration to OEM specifications

- Upgrade Services: Technology upgrades and performance improvements

- Emergency Response: 24/7/365 emergency repair and support services

Digital Maintenance Solutions

- CMMS Integration: Computerized maintenance management system connectivity

- Augmented Reality (AR): AR-guided maintenance and repair procedures

- Digital Work Instructions: Interactive step-by-step maintenance guides

- Remote Diagnostics: Real-time troubleshooting and technical support

- Asset Performance Management: Comprehensive asset lifecycle optimization

Global Supply Chain & Support

Manufacturing Excellence

- ISO 13485: Medical device quality management (food/pharma applications)

- AS9100: Aerospace quality management system certification

- NADCAP: Special process certifications for advanced materials

- Lean Manufacturing: Continuous improvement and waste elimination

- Six Sigma: Statistical process control and quality optimization

Global Service Network

- Regional Service Centers: Strategically located for rapid response

- Local Parts Inventory: Critical spares stocked near customer locations

- Factory-Trained Technicians: Comprehensive certification programs

- Mobile Service Vehicles: Fully equipped for on-site service work

- Remote Support Capability: Video conferencing and AR-assisted troubleshooting

Supply Chain Reliability

- Dual Sourcing Strategy: Multiple qualified suppliers for critical components

- Strategic Inventory: Buffer stock for long-lead-time items

- Supply Chain Visibility: Real-time tracking of orders and deliveries

- Quality Supplier Network: Rigorous supplier qualification and auditing

- Risk Management: Proactive identification and mitigation of supply risks

Customer Support Excellence

- 24/7 Technical Hotline: Immediate access to engineering expertise

- Customer Portal: Online access to documentation, orders, and service history

- Training Academy: Comprehensive educational programs and certifications

- Application Laboratory: Testing facilities for customer-specific requirements

- Performance Guarantees: Comprehensive warranties and performance assurance

Global Headquarters: Contact our DN250 engineering specialists for detailed technical consultation, custom specifications, and comprehensive project support.

Innovation Center: Visit our advanced R&D facilities to experience the latest in knife gate valve technology and participate in collaborative development programs.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.