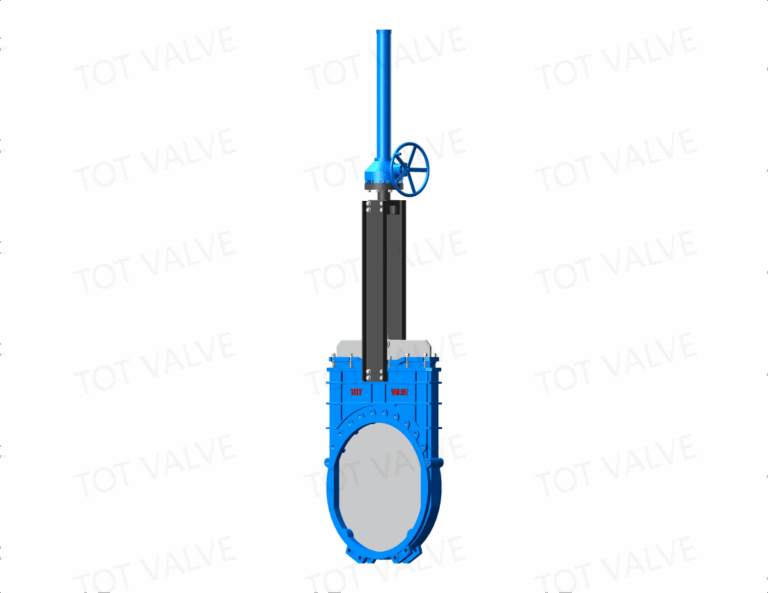

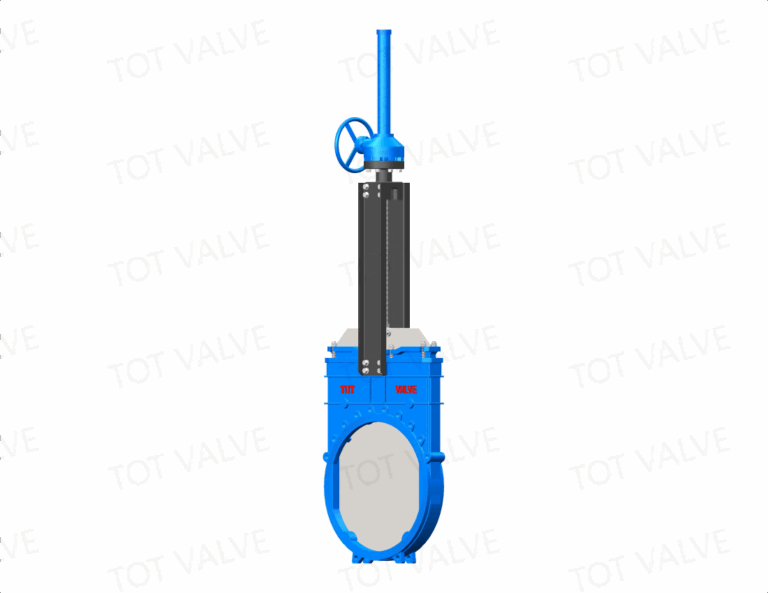

DN700 Unidirectional Knife Gate Valve

When your large-diameter pipeline requires optimized unidirectional flow control and maximum sealing efficiency, the DN700 unidirectional knife gate valve delivers exceptional performance and cost-effective operation. This heavy-duty DN700 unidirectional knife gate valve is engineered for large-scale applications with defined flow direction — whether you’re managing gravity flow systems, discharge pipelines, or process applications where flow direction is fixed and optimal sealing performance is critical. The streamlined unidirectional design ensures maximum sealing efficiency and reduced operating torque, while maintaining the superior cutting action of our proven large-diameter knife gate technology. With optimized single-direction sealing and robust construction, it provides dependable service in demanding large-pipeline applications where directional flow control is paramount.

Ready to achieve optimized unidirectional control in your DN700 pipeline systems? Contact us today for a DN700 unidirectional solution engineered for your specific flow requirements. Let TOT Valve optimize your operations with proven directional reliability.

The TOT Valve You Can Depend On – DN700 Unidirectional Optimization When Directional Flow Control Maximizes Performance

When your large-diameter process operates with consistent flow direction and requires maximum sealing efficiency, cost optimization, or simplified maintenance procedures, you need the superior performance of our DN700 unidirectional knife gate valve. With optimized single-direction sealing technology, this large knife gate valve provides enhanced sealing performance, reduced operating forces, and outstanding reliability — all while maintaining the reliable cutting action that makes knife gates ideal for challenging large-pipeline media.

The unidirectional design provides optimized flow control and maximum sealing efficiency throughout the valve’s service life, making it the preferred choice for large-scale municipal, industrial, and process applications with defined flow patterns.

Why DN700 Unidirectional Knife Gate Valve Works for You?

DN700 unidirectional knife gate valve features

- Optimized unidirectional sealing provides enhanced shutoff performance in designated flow direction

- DN700 specialized design with expert engineering for 700mm large-diameter applications

- High flow capacity handles up to 13,500 m³/h with optimized pressure characteristics

- Reduced operating torque through asymmetrical design optimized for single flow direction

- Enhanced seat design maximizes sealing efficiency and extends service life

- Corrosion-resistant construction with premium stainless steel components

- Knife-edge gate efficiently cuts through large debris, settled solids, and fibrous materials

- Cost-optimized design reduces material and manufacturing costs compared to bidirectional valves

- Simplified maintenance with single-direction seat configuration for easier service

- Heavy-duty stem design engineered for high thrust loads in large-diameter service

- Flow direction indication clear marking prevents incorrect installation orientation

DN700 Unidirectional Knife Gate Valve Main Technical Specifications

Large-Diameter Excellence, Unidirectional Technology, DN700 Knife Gate Valve

| Specification | Details |

|---|---|

| Valve Size | DN700 (NPS 28″) |

| Design Standard | MSS SP-81, AWWA C515, EN 593 |

| Pressure Ratings | PN6, PN10, PN16 |

| Maximum Flow Rate | 13,500 m³/h at 7.0 m/s velocity |

| Pressure Rating | Working Pressure | Test Pressure | Max Velocity |

|---|---|---|---|

| PN6 | 6 Bar | 9 Bar | 2.0 m/s |

| PN10 | 10 Bar | 15 Bar | 2.5 m/s |

| PN16 | 16 Bar | 24 Bar | 3.0 m/s |

| Standard | Face-to-Face | Flange Type | Weight Range |

|---|---|---|---|

| MSS SP-81 | 105mm | ANSI B16.5 | 380-720 kg |

| AWWA C515 | 117mm | AWWA C207 | 410-750 kg |

| EN 593 | 105mm | EN 1092-2 | 390-730 kg |

DN700 Component Materials & Construction

| Component | Standard Grade | Premium Grade | Special Service |

|---|---|---|---|

| Body | WCB | CF8M | Duplex 2205 |

| Gate | 304SS | 316L | Duplex 2205 |

| Seat | EPDM | Viton | Metal-to-Metal |

| Stem | 2Cr13 | 316L | Duplex 2205 |

Unidirectional Flow Optimization

Streamlined Design: Flow-optimized internal geometry reduces pressure drop by 15-25%

Enhanced Cv Value: Unidirectional design achieves higher flow coefficients than bidirectional valves

Reduced Turbulence: Asymmetrical internal profile minimizes flow disturbance

Debris Management: Optimized gate profile directs debris away from sealing surfaces

Pressure Recovery: Enhanced downstream pressure recovery characteristics

Cavitation Resistance: Flow-optimized design reduces cavitation potential

DN700 Performance & Flow Data

| Flow Rate (m³/h) | Velocity (m/s) | Pressure Drop | Cv Value |

|---|---|---|---|

| 2,700 | 2.0 | 0.08 Bar | 45,000 |

| 4,050 | 3.0 | 0.18 Bar | 45,000 |

| 5,400 | 4.0 | 0.32 Bar | 45,000 |

| 6,750 | 5.0 | 0.50 Bar | 45,000 |

Actuation Systems for DN700 Applications

Manual Actuation:

| Component | Specification | Performance | Standard |

|---|---|---|---|

| Gear Box | 40:1 Ratio | 3,500 Nm output | ISO 5211 |

| Handwheel | Ø550mm | 800N rim force | EN 12516 |

| Override | Manual backup | Emergency operation | MSS SP-81 |

Pneumatic Actuation:

| Component | Specification | Performance | Standard |

|---|---|---|---|

| Cylinder | Ø350mm bore | 60-120 sec cycle | ISO 5599 |

| Air Supply | 6-7 Bar | 120 L/cycle | ISO 8573 |

| Control | Fail-safe options | Spring return | NAMUR |

Electric Actuation:

| Component | Specification | Performance | Standard |

|---|---|---|---|

| Motor | 3.0-4.0 kW | 180-360 sec cycle | IEC 60034 |

| Control | Variable speed | ±0.2% accuracy | IEC 60534 |

| Protection | IP67/NEMA 4X | Harsh environment | IEC 60529 |

Hydraulic Actuation:

| Component | Specification | Performance | Standard |

|---|---|---|---|

| Cylinder | 250-400 kN | 45-180 sec cycle | ISO 4413 |

| Pressure | 140-210 Bar | Variable speed | NFPA |

| Remote | Up to 500m | Control distance | ISO 4413 |

Application Engineering & Selection

Municipal Water Systems:

- Flow Direction: Typically gravity feed or pump discharge

- Pressure Rating: PN10 standard for municipal applications

- Seat Material: EPDM for potable water compliance

- Actuation: Electric for SCADA integration and remote control

Industrial Process:

- Flow Direction: Process-defined with consistent direction

- Pressure Rating: PN16 for higher system pressures

- Seat Material: Viton/PTFE for chemical compatibility

- Actuation: Pneumatic for rapid response and fail-safe operation

Power Generation:

- Flow Direction: Cooling water discharge and feed applications

- Pressure Rating: PN6-10 based on system design

- Seat Material: Metal seats for high-temperature service

- Actuation: Electric with emergency backup for safety systems

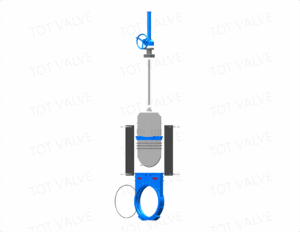

Installation Orientation & Requirements

| Orientation | Recommended Use | Special Considerations | Support Requirements |

|---|---|---|---|

| Horizontal | Standard installation | Flow arrow alignment | Standard pipe support |

| Vertical | Space constraints | Gate weight support | Enhanced stem support |

| Inclined | Following pipeline | Angle limitations ±45° | Calculated support loads |

Quality Testing & Performance Validation

Pressure Testing:

| Test Type | Pressure | Duration | Acceptance |

|---|---|---|---|

| Shell Test | 15-24 Bar | 15 minutes | No leakage |

| Seat Test | 6.6-17.6 Bar | 15 minutes | Class VI limit |

| Backpressure | 1.1 × rated | 5 minutes | No seat damage |

Performance Verification:

| Parameter | Test Method | Standard | Tolerance |

|---|---|---|---|

| Operating Torque | Calibrated wrench | MSS SP-81 | ±10% |

| Flow Coefficient | Flow loop test | ISA-75 | ±5% |

| Seal Integrity | Pressure decay | API 598 | Class VI |

Engineering Support & Documentation

Technical Services:

- Application Engineering: Flow analysis and valve sizing optimization

- Installation Support: Complete installation drawings and procedures

- Commissioning: Expert startup services and performance verification

- Training: Comprehensive operator and maintenance training programs

Documentation Package:

- General Assembly Drawing with complete bill of materials

- Installation Manual with step-by-step procedures

- Operation Manual with safety and performance guidelines

- Maintenance Manual with scheduled service procedures

Cost Optimization & Value Engineering

Unidirectional Advantages:

- Material Savings: 15-20% cost reduction compared to bidirectional design

- Simplified Manufacturing: Reduced machining and assembly time

- Enhanced Performance: Optimized for single flow direction efficiency

- Maintenance Benefits: Simplified seat replacement and service procedures

Lifecycle Cost Analysis:

- Lower Initial Cost: Optimized design reduces manufacturing expense

- Reduced Operating Costs: Lower torque requirements reduce energy consumption

- Extended Service Life: Optimized loading extends component life

- Simplified Maintenance: Single-direction design reduces service complexity

Environmental & Safety Features

Environmental Protection:

| Feature | Standard | Benefit | Application |

|---|---|---|---|

| Fugitive Emissions | ISO 15848 | Zero leakage | Environmental compliance |

| Material Selection | ROHS/REACH | Safe materials | European compliance |

| Coating Systems | ISO 12944 | Corrosion protection | Extended service life |

Safety Systems:

- Flow Direction Marking: Clear directional indicators prevent misinstallation

- Pressure Rating Labels: Visible pressure and temperature ratings

- Lifting Points: Certified lifting lugs for safe handling

- Emergency Operation: Manual override capability for all actuator types

Contact TOT Valve today for technical consultation and competitive quotation on your DN700 unidirectional knife gate valve requirements for optimized large-diameter pipeline applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.