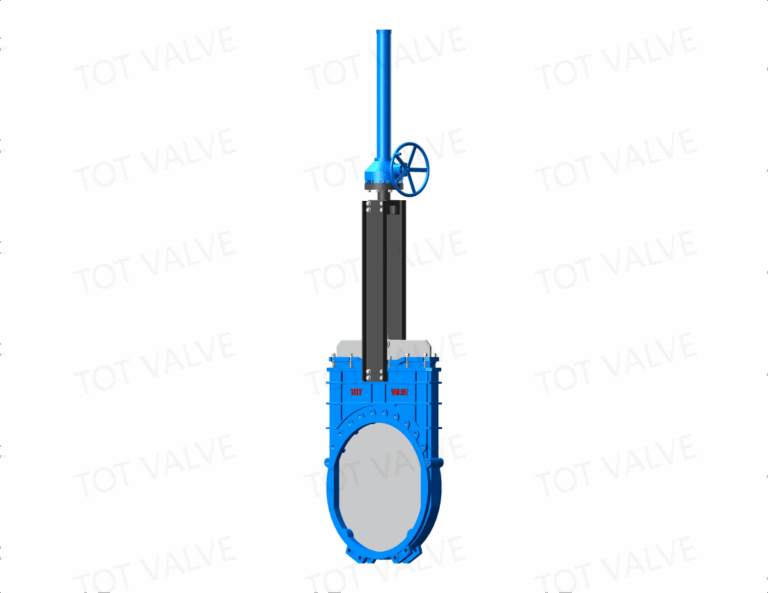

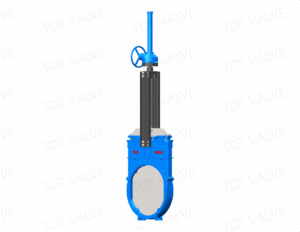

DN800 Bidirectional Knife Gate Valve

When your large-diameter pipeline requires reliable bidirectional sealing and flow control, the DN800 bidirectional knife gate valve delivers exceptional performance and versatile operation. This heavy-duty DN800 bidirectional knife gate valve is engineered for large-scale applications demanding reliable shutoff in both flow directions — whether you’re managing municipal water systems, industrial process pipelines, or mining slurry transport where flow reversal and tight sealing are critical. The robust bidirectional sealing design ensures positive shutoff regardless of flow direction, while maintaining the superior cutting action of our proven large-diameter knife gate technology. With dual sealing capability and heavy-duty construction, it provides dependable service in demanding large-pipeline applications where flow versatility is essential.

Ready to achieve reliable bidirectional control in your large-diameter pipeline systems? Contact us today for a DN800 bidirectional solution engineered for your specific flow requirements. Let TOT Valve secure your operations with proven large-valve reliability.

The TOT Valve You Can Depend On – DN800 Bidirectional Performance When Large-Scale Flow Control Matters

When your large-diameter process requires reliable sealing regardless of flow direction, pipeline flexibility, or emergency isolation capability, you need the superior versatility of our DN800 bidirectional knife gate valve. With advanced dual-direction sealing technology, this large knife gate valve provides reliable shutoff from either direction, exceptional flow characteristics, and outstanding durability — all while maintaining the reliable cutting action that makes knife gates ideal for challenging large-pipeline media.

The bidirectional design provides flexible flow control and consistent sealing performance throughout the valve’s service life, making it the preferred choice for large-scale municipal, industrial, and infrastructure applications.

Why DN800 Bidirectional Knife Gate Valve Works for You?

DN800 bidirectional knife gate valve features

- Dual-direction sealing provides reliable shutoff regardless of upstream/downstream pressure

- Large-diameter expertise with specialized engineering for 800mm applications

- Heavy-duty construction handles high flow rates up to 18,000 m³/h

- Flow reversibility accommodates changing process directions without valve modification

- Symmetrical seat design ensures equal sealing performance in both directions

- Corrosion-resistant stainless steel construction for long-term reliability

- Knife-edge gate efficiently cuts through large debris, settled solids, and fibrous materials

- Multiple actuation options including manual, pneumatic, electric, and hydraulic

- Pressure equalization design prevents pressure lock and ensures smooth operation

- Heavy-duty stem design withstands high thrust loads in large-diameter service

- Emergency isolation capability for rapid pipeline shutoff in both directions

DN800 Bidirectional Knife Gate Valve Main Technical Specifications & Performance

Large-Diameter Excellence, Bidirectional Sealing Technology, DN800 Knife Gate Valve

| Specification | Details |

|---|---|

| Valve Size | DN800 (NPS 32″) |

| Design Standard | MSS SP-81, AWWA C515, EN 593 |

| Pressure Rating | PN6, PN10, PN16 (6Bar, 10Bar, 16Bar) |

| Maximum Flow Capacity | 18,000 m³/h at 2 m/s velocity |

| Bidirectional Pressure | Full pressure rating in both flow directions |

| Face-to-Face Dimension | 105mm (MSS SP-81), 117mm (AWWA C515) |

| Flange Standards | EN1092-2, ASME B16.5, GB/T9113, JIS B2220 |

| Body Materials | WCB, CF8, CF8M, Duplex 2205 |

| Gate Materials | 304SS, 316SS, 316L, Duplex 2205 |

| Seat Options | EPDM, NBR, Viton, Metal-to-Metal |

| Temperature Range | -20°C to +120°C (EPDM), up to +200°C (Metal seats) |

| Testing Standards | EN 12266-1, API 598, MSS SP-81 |

| Applications | Municipal Water, Industrial Process, Mining, Power Generation |

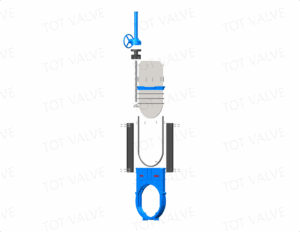

| Installation Orientation | Horizontal, Vertical, Inclined (any angle) |

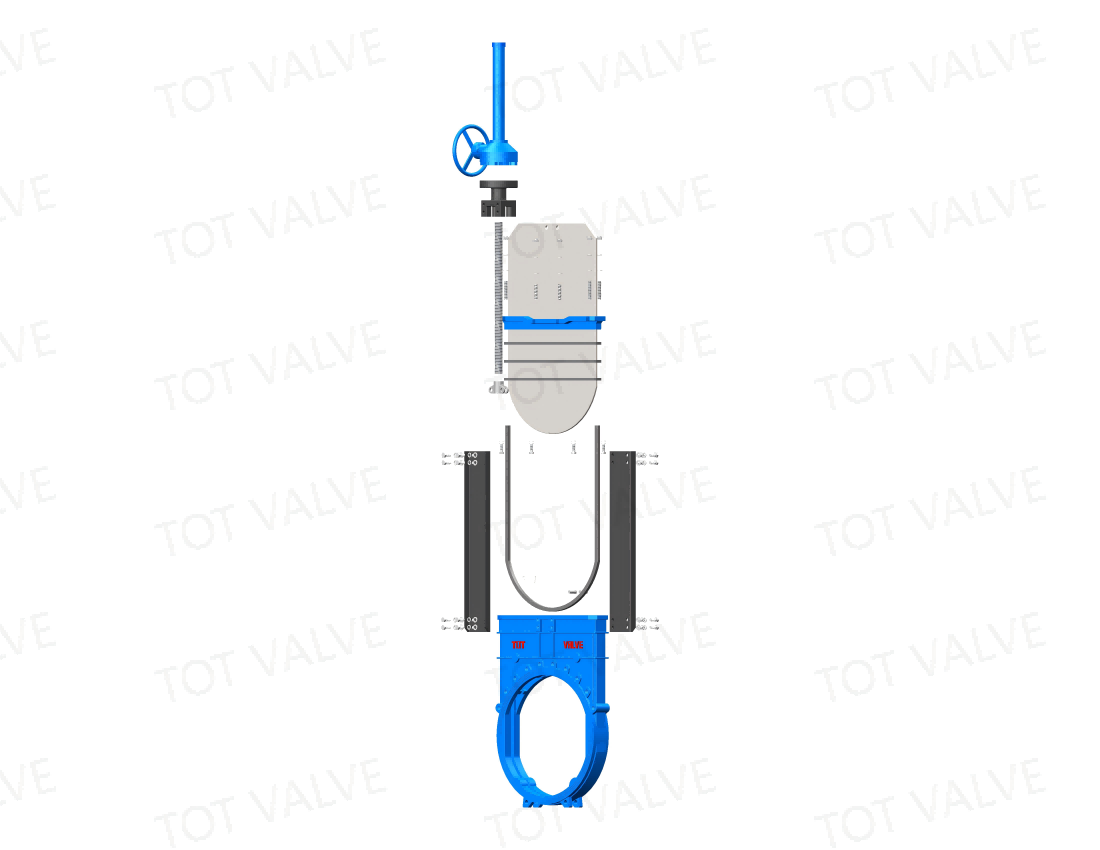

DN800 Bidirectional Sealing Technology

Symmetrical Seat Design: Identical sealing performance regardless of flow direction

Pressure-Balanced Operation: Gate design minimizes operating torque under pressure

Dual Seal Configuration: Primary and backup sealing for critical applications

Flow-Through Design: Unobstructed bore maintains maximum flow capacity

Debris Handling: Large gate opening accommodates oversized debris passage

Thermal Expansion: Compensated design handles thermal cycling in large pipelines

DN800 Valve Dimensional Data & Installation Requirements

| Parameter | Metric (mm) | Imperial (inch) | Notes |

|---|---|---|---|

| Nominal Diameter | DN800 | 32″ | Pipeline bore size |

| Face-to-Face (FF) | 105-117 | 4.1-4.6″ | Per MSS SP-81/AWWA |

| Flange Diameter | 1000-1168 | 39.4-46.0″ | Depends on standard |

| Bolt Circle | 962-1092 | 37.9-43.0″ | Per flange rating |

| Gate Thickness | 8-12 | 0.31-0.47″ | Based on pressure rating |

| Overall Height | 1450-2200 | 57-87″ | Depends on actuator |

| Valve Weight | 450-850 kg | 990-1875 lbs | Varies with materials |

| Actuator Weight | 50-500 kg | 110-1100 lbs | Depends on type |

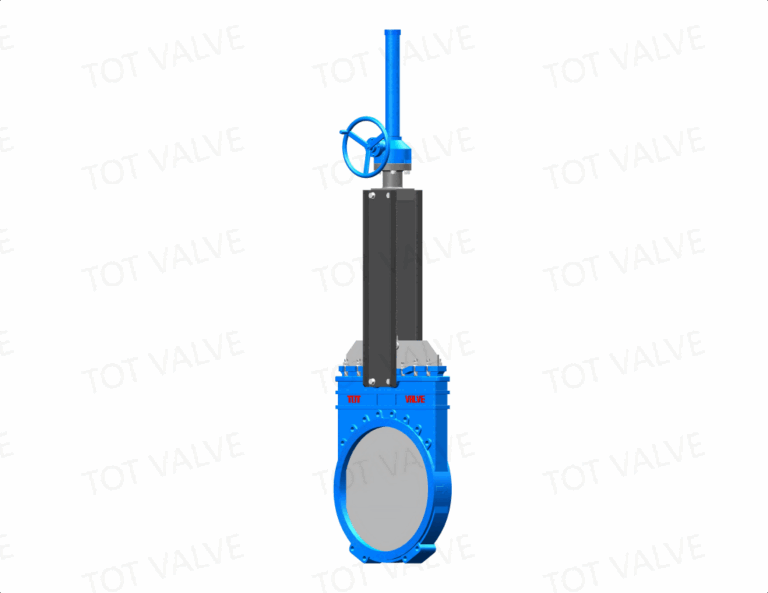

Actuation Options for DN800 Applications

Manual Operation:

- Gear Box Ratio: 25:1 to 50:1 reduction for manageable operating force

- Operating Torque: 2,500-5,000 Nm depending on pressure and media

- Handwheel Diameter: 500-600mm for optimal mechanical advantage

- Chain Wheel Option: Available for elevated or remote installations

Pneumatic Actuation:

- Actuator Size: Ø320-400mm cylinder for reliable operation

- Air Pressure: 6-7 Bar supply pressure for full force capability

- Operating Time: 45-120 seconds full stroke depending on configuration

- Fail-Safe Options: Spring return or stored energy for emergency closure

Electric Actuation:

- Motor Power: 2.2-5.5 kW for consistent operation under load

- Operating Time: 120-300 seconds programmable stroke time

- Position Accuracy: ±0.2% with encoder feedback systems

- Control Integration: Full DCS/SCADA compatibility with digital protocols

Hydraulic Actuation:

- Cylinder Force: 150-400 kN output force for maximum differential pressure

- Operating Pressure: 140-210 Bar hydraulic system pressure

- Operating Time: 30-180 seconds variable speed control

- Remote Distance: Up to 500m from hydraulic power unit

Application-Specific Configurations

Municipal Water Systems:

- Seat Material: EPDM for potable water compliance

- Body Material: CF8/CF8M stainless steel for corrosion resistance

- Actuation: Electric with position feedback for SCADA integration

- Special Features: NSF-61 certification, epoxy coating options

Industrial Process:

- Seat Material: Viton/PTFE for chemical compatibility

- Body Material: CF8M/Duplex for aggressive media resistance

- Actuation: Pneumatic with fail-safe configuration

- Special Features: Steam tracing, insulation jackets available

Mining & Slurry Service:

- Seat Material: Metal-to-metal for abrasion resistance

- Body Material: WCB with hard-facing options

- Actuation: Hydraulic for maximum force capability

- Special Features: Replaceable seat rings, debris deflectors

Power Generation:

- Seat Material: High-temperature Viton or metal seats

- Body Material: CF8M with thermal stress analysis

- Actuation: Electric with SIL-rated control systems

- Special Features: Fire-safe design, emergency quick-close capability

Quality Assurance & Testing Protocol

Every DN800 TOT bidirectional knife gate valve undergoes comprehensive testing:

- Hydrostatic shell testing at 1.5x rated pressure from both directions

- Bidirectional seat testing per MSS SP-81 standards

- Flow coefficient verification through computational and physical testing

- Actuator performance testing under simulated operating conditions

- Thermal cycling testing for large-diameter thermal stress analysis

- Material certification with full Mill Test Certificate documentation

Installation & Engineering Support

Installation Planning: Complete installation drawings and lifting procedures

Foundation Design: Structural analysis and foundation recommendations

Pipeline Integration: Thermal expansion analysis and support design

Commissioning Support: Expert startup services and performance verification

Operator Training: Comprehensive training programs for safe operation

Maintenance Planning: Predictive maintenance programs and spare parts recommendations

Large-Valve Expertise & Manufacturing

Specialized Manufacturing: Dedicated large-valve production facilities

Quality Control: Enhanced inspection procedures for large-diameter components

Transportation: Specialized handling and shipping for oversized valves

Project Management: Dedicated project teams for large-valve installations

Technical Support: Expert engineering support throughout valve lifecycle

Global Capability: Manufacturing and service locations worldwide

Performance Guarantees & Warranties

Sealing Performance: Guaranteed bidirectional sealing per specification

Flow Performance: Verified Cv values and pressure drop characteristics

Operating Performance: Guaranteed actuator force and speed requirements

Service Life: Extended warranty programs for critical applications

Performance Testing: Factory acceptance testing with customer witness

Ongoing Support: Comprehensive aftermarket support and service programs

Contact TOT Valve today for technical consultation and competitive quotation on your DN800 bidirectional knife gate valve requirements for large-diameter pipeline applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.