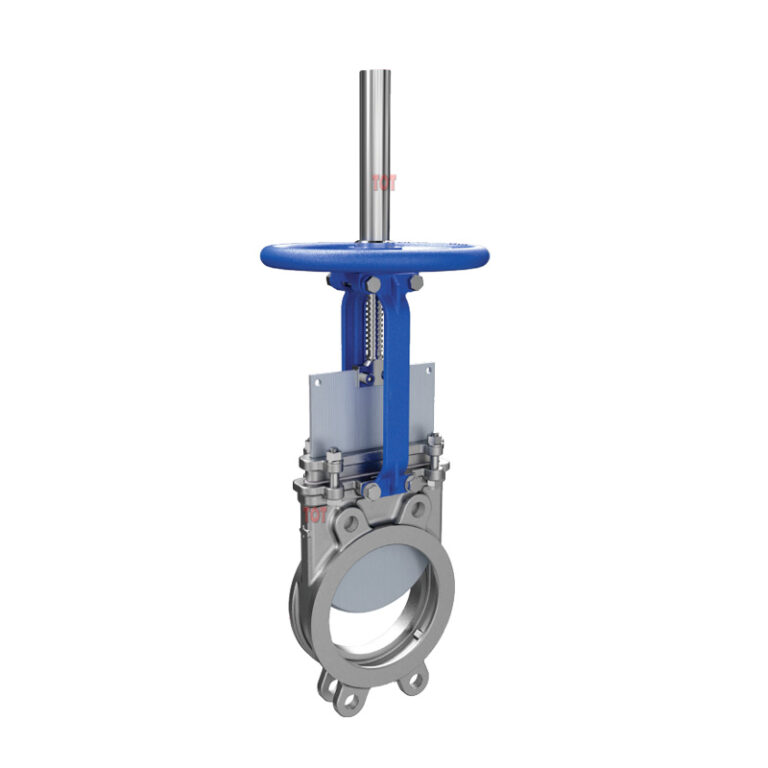

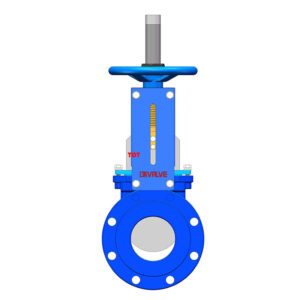

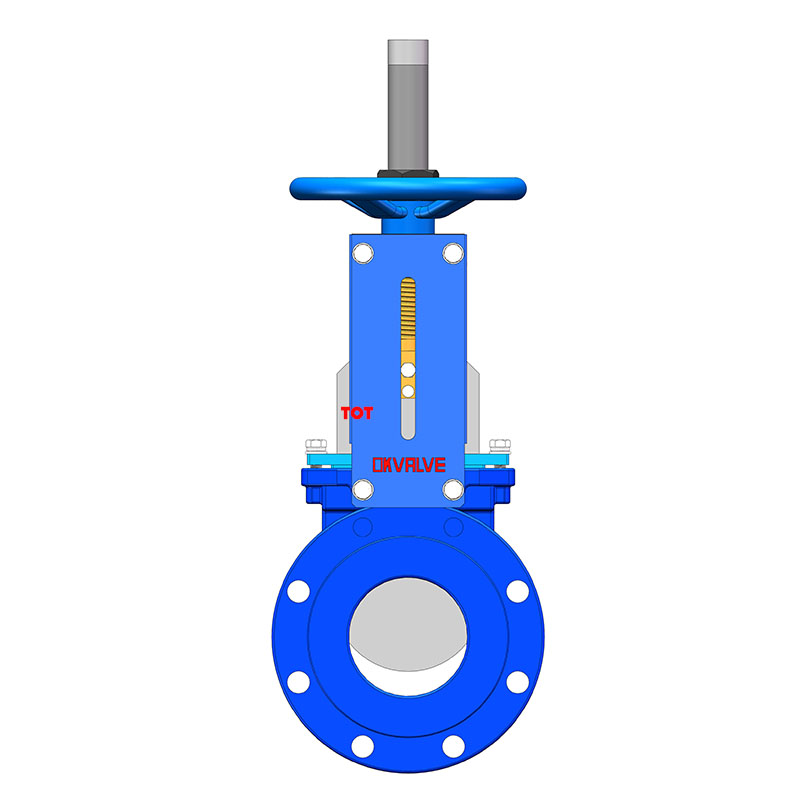

Flanged Type Knife Gate Valve

When you need maximum strength and reliability in high-pressure applications, a flanged type knife gate valve delivers uncompromising performance. This heavy-duty stainless steel flanged knife gate valve is engineered for the most demanding industrial applications — whether you’re handling high-pressure slurry, abrasive pulp, or corrosive chemicals. The integral flanged ends provide superior structural integrity and eliminate potential leak paths, making it ideal for critical processes where safety and reliability cannot be compromised. With robust construction and proven design, it ensures long-term performance in heavy industrial environments.

Ready to enhance your critical flow control systems? Contact us today for a flanged valve solution engineered to your exact pressure and performance requirements. Let TOT Valve secure your operations.

The TOT Valve You Can Depend On – Maximum Strength for Critical Applications

When your process involves high-pressure slurry, abrasive fluids, or corrosive chemicals in mission-critical applications, you need the ultimate reliability of our flanged type knife gate valve. With its integral flanged construction, this knife gate valve provides exceptional structural strength, zero-leakage flanged connections, and superior pressure containment — engineered to handle your most demanding operating conditions.

The flanged design provides maximum mechanical strength and eliminates body-to-flange joint potential failure points, making it the preferred choice for high-pressure, high-temperature, and critical service applications.

Why Flanged Type Knife Gate Valve Works for You?

- Corrosion-resistant stainless steel (SS304/316/316L) withstands the harshest industrial environments.

- Integral flanged construction eliminates body-flange joints for maximum structural integrity.

- Heavy-duty design handles high pressure and temperature applications with confidence.

- Knife-edge gate cuts through the toughest media including fibrous pulp, thick slurry, and crystallized materials.

- Zero-leakage flanged connections ensure environmental compliance and worker safety.

- Multiple seat options deliver bubble-tight shut-off for your specific application needs.

- Full range of actuators – manual, pneumatic, electric, or gear operated for precise control.

- Robust construction designed for continuous operation in demanding industrial environments.

- Enhanced safety margins exceed standard pressure ratings for critical applications.

- Full bore design maintains maximum flow capacity and minimizes pressure drop.

- Field-proven reliability with extensive track record in heavy industry applications.

Flanged Knife Gate Valve Main Technical Specifications & Performance

Uni-directional/Bi-directional Sealing, Heavy-Duty Flanged Body, Knife Gate Valve

| Specification | Details |

|---|---|

| Design & Manufacturing Standard | MSS SP-81, API 6D, AWWA C515 |

| Size Range | DN50 to DN1500 mm; NPS 2″-60″ (Customized to Your Request) |

| Pressure Ratings | PN10, PN16, PN25, ANSI 150/300/600, 5K/10K/16K, etc. |

| Working Pressure Classification | DN50–DN200: 16Bar; DN250–DN400: 10Bar; DN450–DN600: 6Bar; DN700–DN1500: 4Bar |

| Face-to-Face Standard | MSS SP-81, AWWA C515, API 6D |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Inspection & Testing Standard | MSS SP-81, API 598, EN 12266 |

| Body Materials | WCB, WC6, WC9, CF8, CF3, CF8M, CF3M, 4A, 5A, 6A, 904L, Duplex 2205 |

| Temperature Range | -29°C to +425°C (-20°F to +800°F) depending on materials |

| Temperature–Pressure Rating Standards | GB/T12224–2007, ASME B16.34–2009, ISO7005–1 |

| Applications | Power Plants, Pulp & Paper, Mining, Heavy Chemical, Petrochemical, Steel Mills, Cement Plants, Municipal Water Treatment, Industrial Wastewater |

| Actuation Methods | Manual, Pneumatic, Electric, Hydraulic, Gear Drive, Chain Drive, Lever |

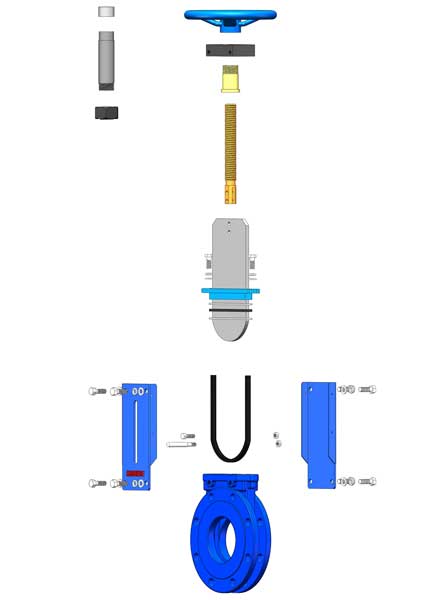

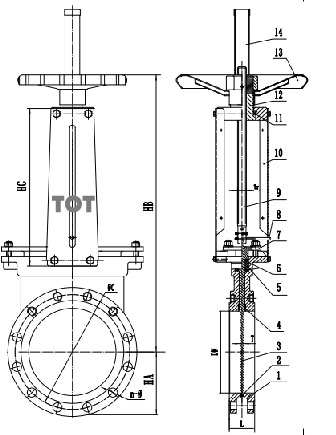

Flanged Knife Gate Valve Main Components and Materials

| Part Name | Material Options | |||

|---|---|---|---|---|

| WCB | CF8 | CF8M | Duplex 2205 | |

| Body | WCB | CF8 | CF8M | Duplex 2205 |

| Flanged Ends | WCB | CF8 | CF8M | Duplex 2205 |

| Gate | 304 | 316 | 316L | 2205 |

| Seat | STL, EPDM, or PTFE | STL, EPDM, or PTFE | STL, EPDM, or PTFE | Metal Seated |

| O-ring | NBR | NBR | EPDM | FKM |

| Bonnet | WCB | CF8 | CF8M | Duplex 2205 |

| Packing | PTFE | PTFE | PTFE | PTFE/Grafoil |

| Yoke | Q235 | 304 | 316 | 2205 |

| Stem | 2Cr13 | 316 | 316L | 2205 |

| Stem Nut | Brass | Brass | Brass | Duplex Steel |

| Guide Pin | 65Mn | 304 | 316 | 2205 |

| Support Bracket | WCB | CF8 | CF8M | Duplex 2205 |

| Handwheel | GGG30 | GGG30 | GGG30 | Steel |

| Stem Protector | 304 | 304 | 316 | 2205 |

| Fasteners | A193-B7/A194-2H | A4-70 | A4-80 | Super Duplex |

TOT Valve Tailored for Your Critical Systems – Premium Custom Options

You can customize this flanged valve for your most demanding system requirements:

Gate Finish: Mirror polish, plasma spray coating, hardened edge treatment, or duplex stainless

Seat Type: EPDM, PTFE, Viton, PEEK, or metal seated with Stellite/Inconel overlay

Actuation Options: Pneumatic actuator with fail-safe springs, electric motor with variable speed drives, hydraulic actuator for high-torque applications

Body Coating: High-performance epoxy, ceramic lining, Hastelloy overlay, PFA/PTFE lining for maximum chemical resistance

Automation Package: Full automation with positioners, limit switches, solenoid valves, and SCADA integration

Special Features: Heating jackets, cryogenic service modifications, fire-safe design, fugitive emission compliance

Extended Warranties: Performance guarantees for critical service applications

Flanged Knife Gate Valve Dimensions

TOT valve can provide you with various sizes of flanged knife gate valve. We have listed some flanged type knife gate valve sizes for PN16 for your reference.

If you don’t have the flanged type knife gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | NPS(in) | ||||||||

| 50 | 2″ | 65 | 135 | 106 | 100 | 129 | 85 | 200 | 420 |

| 65 | 2-1/2″ | 68 | 155 | 106 | 115 | 147 | 85 | 200 | 465 |

| 80 | 3″ | 70 | 175 | 106 | 121 | 168 | 85 | 220 | 510 |

| 100 | 4″ | 75 | 163 | 106 | 138 | 192 | 85 | 220 | 580 |

| 125 | 5″ | 82 | 192 | 120 | 160 | 215 | 87 | 270 | 675 |

| 150 | 6″ | 85 | 216 | 130 | 185 | 245 | 87 | 300 | 755 |

| 200 | 8″ | 95 | 271 | 130 | 235 | 302 | 105 | 330 | 910 |

| 250 | 10″ | 105 | 335 | 140 | 300 | 355 | 105 | 380 | 1140 |

| 300 | 12″ | 115 | 381 | 160 | 350 | 401 | 105 | 430 | 1285 |

| 350 | 14″ | 125 | 436 | 180 | 400 | 465 | 117 | 480 | 1475 |

| 400 | 16″ | 135 | 505 | 180 | 455 | 511 | 117 | 480 | 1635 |

| 450 | 18″ | 145 | 568 | 200 | 510 | 578 | 130 | 530 | 1820 |

| 500 | 20″ | 155 | 632 | 220 | 565 | 645 | 130 | 580 | 2005 |

Critical Service Applications

Power Generation: Ash handling, FGD systems, cooling water intake

Pulp & Paper: Stock preparation, bleaching systems, waste treatment

Mining: Tailings handling, concentrate pipelines, process water

Chemical Processing: Reactor isolation, catalyst handling, waste neutralization

Steel Industry: Blast furnace gas cleaning, water treatment, slag handling

Municipal: Raw water intake, sludge handling, chemical feed systems

Enhanced Safety & Compliance Features

Pressure Safety: Design margins exceed ASME standards for critical applications

Environmental Protection: Fugitive emission testing per ISO 15848

Fire Safety: API 607/API 6FA fire testing available

Quality Assurance: Full material traceability and 3.1 certification

Performance Verification: Factory acceptance testing with customer witness points

Extended Testing: Cycle testing, endurance testing, and accelerated life testing available

Installation & Maintenance Advantages

Structural Integrity: Integral flanged construction eliminates weak points

Alignment: Precision-machined flanges ensure perfect pipeline alignment

Accessibility: Extended bonnets and rising stems for easy maintenance access

Serviceability: Replaceable seats and packing without removing valve from line

Documentation: Complete installation, operation, and maintenance manuals provided

Support: Global service network for on-site maintenance and emergency response

Contact TOT Valve today for engineering consultation and competitive quotation on your flanged knife gate valve requirements for critical service applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.