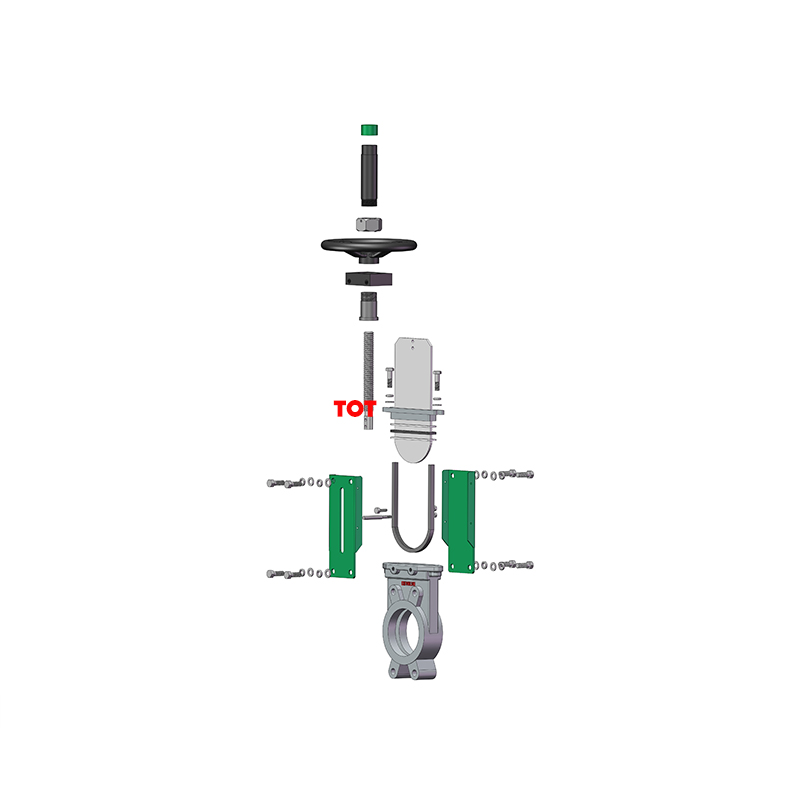

Manual Knife Gate Valve

When your application requires reliable manual control and cost-effective operation, a manual knife gate valve delivers exceptional performance and operator convenience. This robust manual knife gate valve is engineered for applications demanding precise flow control — whether you’re managing wastewater treatment systems, pulp and paper processes, or mining operations where hands-on control is essential. The ergonomic handwheel design ensures smooth operation even under high differential pressures, while maintaining the superior cutting action of our proven knife gate technology. With intuitive manual operation and rugged construction, it provides dependable service in demanding industrial environments where automated systems are unnecessary or impractical.

Ready to achieve reliable manual control in your critical flow applications? Contact us today for a manual solution engineered for your specific operational requirements. Let TOT Valve empower your operations with proven manual reliability.

The TOT Valve You Can Depend On – Manual Operation When Simplicity Meets Performance

When your process requires hands-on control, cost-effective operation, or backup capability during power outages, you need the reliable performance of our manual knife gate valve. With precision-engineered handwheel operation, this knife gate valve provides smooth manual control, exceptional operator feedback, and outstanding durability — all while maintaining the reliable cutting action that makes knife gates ideal for challenging media.

The manual operation design provides immediate response and precise positioning throughout the valve’s service life, making it the preferred choice for applications requiring operator control and system simplicity.

Why Manual Knife Gate Valve Works for You?

- Ergonomic handwheel design ensures smooth operation with minimal operator effort

- High-efficiency ACME thread provides optimal mechanical advantage for easy operation

- Position indication offers clear visual feedback of valve position

- Non-rising stem design saves valuable installation space and protects threads

- Self-adjusting packing maintains stem sealing without frequent maintenance

- Corrosion-resistant construction ensures long-term reliability in harsh environments

- Knife-edge gate cuts through fibrous materials, settled solids, and viscous media efficiently

- No external power required provides operation during power outages or remote locations

- Low maintenance design minimizes operational costs and downtime

- Multiple mounting orientations accommodates various installation requirements

- Robust thrust bearing system handles high operating loads with smooth operation

Manual Knife Gate Valve Main Technical Specifications & Performance

Reliable Manual Operation, Precision Engineering, Knife Gate Valve

| Specification | Details |

|---|---|

| Design & Manufacturing Standard | MSS SP-81, AWWA C515 |

| Size Range | DN50 to DN1200 mm; NPS 2″-48″ (Customized to Your Request) |

| Pressure Ratings | PN6, PN10, PN16, ANSI 150Psi, 5K/10K, etc. |

| Working Pressure Classification | DN50–DN300: 16Bar; DN350–DN500: 10Bar; DN600–DN800: 6Bar; DN900–DN1200: 4Bar |

| Operating Torque | Optimized for manual operation (detailed torque charts available) |

| Face-to-Face Standard | MSS SP-81, AWWA C515 |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Testing Standard | MSS SP-81, API 598, EN 12266-1 |

| Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature Range | -29°C to +200°C (depending on material selection) |

| Handwheel Materials | Ductile Iron (GGG30), Cast Iron (GG25), Stainless Steel |

| Thread Standards | ACME, Metric Trapezoidal, Square Thread |

| Applications | Water Treatment, Mining, Pulp & Paper, Food Processing, Chemical, Municipal |

| Operation Type | Manual Handwheel, Chain Wheel (for elevated installations) |

Manual Knife Gate Valve Main Components and Materials

| Part Name | Material Options | ||

|---|---|---|---|

| WCB | CF8 | CF8M | |

| Body | WCB | CF8 | CF8M |

| Gate | 304SS | 316SS | 316L |

| Seat | EPDM/Metal | EPDM/Metal | EPDM/Metal |

| Bonnet | WCB | CF8 | CF8M |

| Handwheel | GGG30 | GGG30 | 316SS |

| Stem | 2Cr13 | 316SS | 316L |

| Stem Nut | Bronze | Bronze | Bronze |

| Thrust Bearing | Bronze/PTFE | Bronze/PTFE | Bronze/PTFE |

| Packing | PTFE/Graphite | PTFE/Graphite | PTFE/Graphite |

| Packing Gland | WCB | CF8 | CF8M |

| Yoke | Q235 | 304SS | 316SS |

| Position Indicator | Aluminum | Aluminum | 316SS |

| Stem Protector | 304SS | 304SS | 316SS |

| O-rings | NBR/EPDM | NBR/EPDM | EPDM/Viton |

| Fasteners | A193-B7 | A4-70 | A4-80 |

| Handwheel Nut | Steel | 304SS | 316SS |

Advanced Manual Operation Technology

ACME Thread Design: Precision ACME threads provide optimal mechanical advantage and smooth operation

Self-Locking Feature: Thread design prevents valve drift under system pressure

Ergonomic Handwheel: Designed for comfortable operation with proper rim speed and diameter

Thrust Bearing System: High-quality bearings ensure smooth operation throughout service life

Position Indication: Clear visual indication of valve position and travel limits

Stem Protection: Protective covers prevent contamination and operator contact with moving parts

TOT Valve Tailored for Your Manual Operation Applications – Versatile Control Options

You can customize this manual knife gate valve for your exact operational requirements:

Handwheel Options:

- Standard Handwheel: Cast iron construction for general service applications

- Stainless Steel Handwheel: Corrosion-resistant for harsh environments

- Extended Handwheel: Larger diameter for reduced operating effort

- Chain Wheel: For elevated or hard-to-reach installations

Operating Configurations:

- Direct Mount: Standard handwheel directly mounted to stem

- Gear Drive: Reduction gearing for high-torque applications

- Chain Operation: Extended chain wheel for remote operation

- Portable Handwheel: Removable handwheel for security applications

Special Features:

- Position indicators: Mechanical position indication with limit stops

- Locking devices: Padlock capability for security applications

- Weather protection: Handwheel covers for outdoor installations

- Stem extensions: For buried valve applications

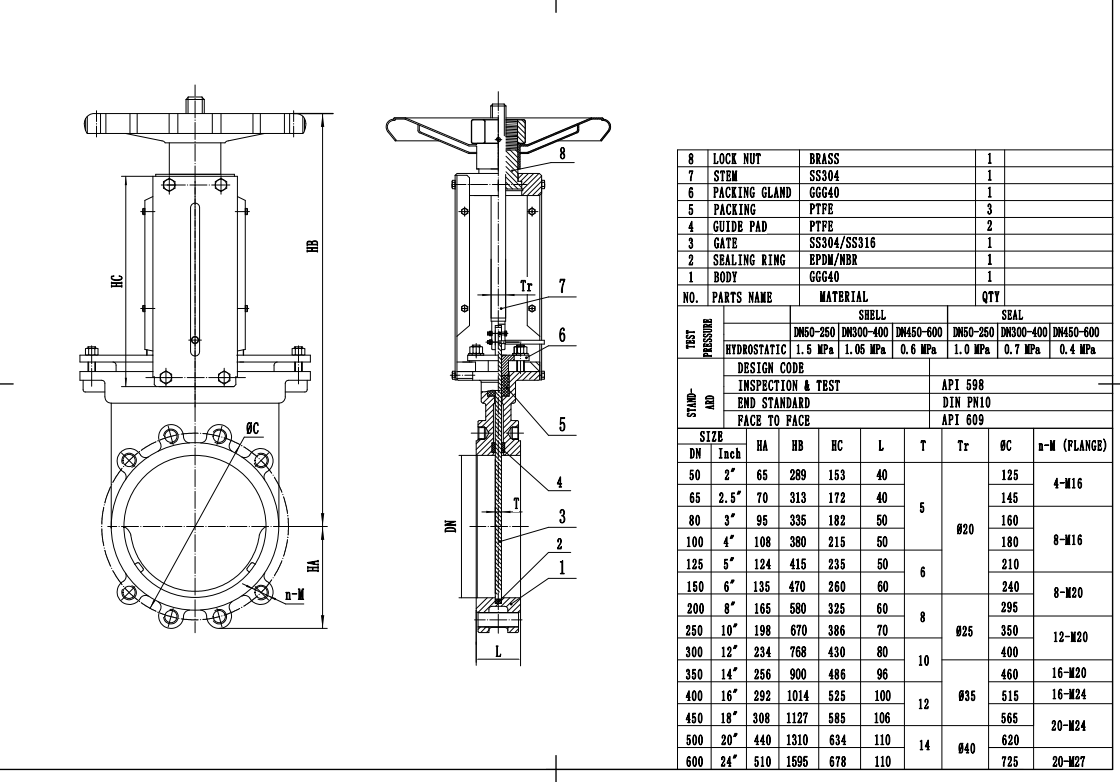

Manual Knife Gate Valve Dimensions

TOT valve can provide you with various sizes of manual knife gate valve. We have listed some manual knife gate valve sizes for PN16 for your reference.

If you don’t have the manual knife gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | Handwheel Ø | Operating Torque (Nm) |

|---|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | NPS(in) | |||||||||

| 50 | 2″ | 48 | 135 | 106 | 100 | 129 | 85 | 180 | 395 | 200mm |

| 65 | 2-1/2″ | 48 | 155 | 106 | 115 | 147 | 85 | 180 | 436 | 200mm |

| 80 | 3″ | 51 | 175 | 106 | 121 | 168 | 85 | 200 | 478 | 200mm |

| 100 | 4″ | 51 | 163 | 106 | 138 | 192 | 85 | 200 | 545 | 250mm |

| 125 | 5″ | 57 | 192 | 120 | 160 | 215 | 87 | 250 | 630 | 250mm |

| 150 | 6″ | 57 | 216 | 130 | 185 | 245 | 87 | 280 | 705 | 300mm |

| 200 | 8″ | 70 | 271 | 130 | 235 | 302 | 105 | 300 | 850 | 300mm |

| 250 | 10″ | 70 | 335 | 140 | 300 | 355 | 105 | 350 | 1065 | 350mm |

| 300 | 12″ | 76 | 381 | 160 | 350 | 401 | 105 | 400 | 1200 | 400mm |

| 350 | 14″ | 76 | 436 | 180 | 400 | 465 | 117 | 450 | 1375 | 450mm |

| 400 | 16″ | 89 | 505 | 180 | 455 | 511 | 117 | 450 | 1525 | 500mm |

Operating Torque Guide

| Application | Pressure (Bar) | Torque Factor | Recommended Features |

|---|---|---|---|

| Clean Water | Up to 10 | Standard | Standard handwheel |

| Wastewater/Sludge | Up to 6 | 1.2x Standard | Extended handwheel |

| Abrasive Media | Up to 4 | 1.5x Standard | Gear operator recommended |

| High Pressure | Up to 16 | 1.8x Standard | Gear operator required |

| Viscous Media | Variable | 1.3x Standard | Chain wheel option |

| Emergency Service | Variable | Standard | Portable handwheel |

Performance Advantages & Features

Smooth Operation: Precision-engineered components ensure consistent operation throughout service life

Minimal Operating Effort: Optimized thread design reduces required operating force

Immediate Response: Direct mechanical connection provides instant valve response

Position Feedback: Clear visual indication of valve position prevents misoperation

No Power Dependency: Reliable operation during power outages or in remote locations

Low Maintenance: Simple mechanical design minimizes maintenance requirements

Quality Assurance & Certification

Every TOT manual knife gate valve undergoes rigorous testing:

- Hydrostatic shell testing at 1.5x working pressure

- Seat leakage testing per applicable standards

- Operating torque verification under rated pressure conditions

- Thread pitch and surface finish inspection

- Handwheel torque and fatigue testing

- Material certification with full traceability documentation

Installation & Maintenance Benefits

Simple Installation: Standard flange connections with no external power requirements

Ergonomic Design: Handwheel positioned for comfortable operator access

Easy Maintenance: Accessible packing adjustment without valve removal

Predictive Maintenance: Operating torque monitoring indicates component condition

Field Service: All wearing parts accessible for field replacement

Training Support: Operator training programs for safe and efficient operation

Safety & Operational Guidelines

Operating Safety: Clear position indication prevents accidental operation

Torque Limits: Specified maximum torques prevent component damage

Environmental Protection: Weather-resistant construction for outdoor service

Security Options: Locking devices available for restricted access applications

Ergonomic Standards: Handwheel design meets occupational safety requirements

Emergency Operation: Manual override capability for automated valve backup

Cost Benefits & Economics

No Operating Costs: Zero energy consumption for valve operation

Minimal Maintenance: Simple mechanical design reduces service requirements

Long Service Life: Robust construction ensures extended operational life

No Control System: Eliminates need for expensive automation equipment

Operator Training: Simple operation requires minimal training investment

Spare Parts: Common mechanical components readily available

Contact TOT Valve today for technical consultation and competitive quotation on your manual knife gate valve requirements for reliable manual operation applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.