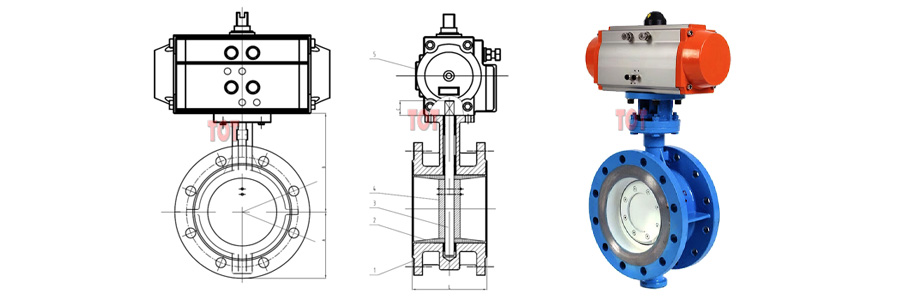

Pneumatic Ceramic Butterfly Valve

Pneumatic ceramic butterfly valve is a ceramic lined butterfly valve, and its sealing part is made of high-quality structural ceramic (alumina, zirconium oxide) material by precision machining. The pneumatic ceramic butterfly valve adopts an eccentric structure to reduce the friction of moving parts, so that its service life in your conveying system application will be extended.

If you need our pneumatic ceramic butterfly valve, please contact us immediately.

Description

TOT Valve body adopts electrostatic powder thermal spraying process, spraying thickness 250μm, valve body is heated at 200℃ for 3 hours, powder is cured at 180℃ for 2 hours, and surface adhesion is 2 times higher than ordinary powder after natural cooling, which is more environmentally friendly and more weather-resistant, ensuring that the valve body will not change color for 36 months.

The materials of the ceramic seal ring, O-ring and butterfly plate of the ceramic lined butterfly valve provided by TOT Valve can be replaced according to your needs and uses.

The pneumatic ceramic butterfly valve adopts a full-bore design, RF flange end and handwheel operation, which can provide reliable fluid regulation for your different industrial needs.

The ceramic we use is aluminum oxide (Al₂O₃) or zirconium oxide (ZrO₂) composition, which has a fracture toughness 2.5 times that of other nitride or carbide ceramics and a wear resistance 12 times that of stainless steel, ensuring your service life.

When you have multiple use environments, we can provide you with valve bodies of different materials according to your different applications, such as super duplex stainless steel, Hastelloy, stainless steel, cast steel, etc.

We are professional industrial valve manufacturers and exporters. We can not only provide you with a variety of ANSI, JIS and DIN flange standards, but also provide you with pneumatic ceramic butterfly valves of ANSI 150 and 300 grade standards.

Design Standard of Pneumatic Ceramic Butterfly Valve Implemented by TOT Valve

| Nominal Pressure | Design and Manufacture | Face-to-Face Dimension | Flange Dimension | Inspection and Test | Valve Testing |

|---|---|---|---|---|---|

| PN10/16, ANSI Class 150LB/300LB | GB/T 12224, ASME B16.34 | Manufacturers Standard, ASME B16.5 & B16.47 | JB/T 79.1, ANSI B16.5, DIN 2543, JIS B2020 | GB/T 9092, ASME B16.34 | API 598 |

Pneumatic Ceramic Butterfly Valve Features

- The pneumatic head adopts a double piston rack structure, with precise meshing, high efficiency and constant output torque

- Adopt eccentric structure to reduce the friction of moving parts

- Provide you with wafer type, lug type or flange type connection

- Light weight, short end face distance, small operating torque

- Can be used as a switch valve or regulating valve

- Ceramic valve seat and butterfly plate seal are wear-resistant

- Longer service life

- Market competitive price

Main Component Materials

| Number | Name | Material | Number | Name | Material |

|---|---|---|---|---|---|

| 1 | Valve Body | WCB | 9 | Filler | 304+ Flexible Graphite |

| 2 | Valve Seat Pressure Plate | 25# | 10 | Packing Bushing | 1Cr13 |

| 3 | Shaft Sleeve | PTFE | 11 | Hold-down Grid | WCB |

| 4 | Valve Seat | Engineering Ceramics | 12 | Support | Q235 |

| 5 | Sealing Ring Pressure Plate | 25# | 13 | Double Headed Studs | B7 |

| 6 | Sealing Ring | Engineering Ceramics | 14 | Nut | 2H |

| 7 | Disc | WCB | 15 | Cylinder Piston Rod | #45 Chrome Plating |

| 8 | Valve Stem | 2Cr13 | 16 | Cylinder | Assembly |

Main Appearance and Connection Dimensions

| DN | NPS(inch) | A | B | C | L |

|---|---|---|---|---|---|

| DN50 | 2″ | 69.5 | 126.5 | 32 | 108 |

| DN65 | 2.5″ | 72 | 136 | 32 | 112 |

| DN80 | 3″ | 88 | 146 | 32 | 114 |

| DN100 | 4″ | 96.5 | 158 | 32 | 127 |

| DN125 | 5″ | 115 | 179 | 32 | 140 |

| DN150 | 6″ | 126 | 197 | 32 | 140 |

| DN200 | 8″ | 161 | 230 | 45 | 152 |

| DN250 | 10″ | 199 | 271 | 45 | 165 |

| DN300 | 12″ | 215 | 305 | 45 | 178 |

| DN350 | 14″ | 261 | 350 | 45 | 190 |

| DN400 | 16″ | 290 | 381 | 51 | 216 |

| DN450 | 18″ | 307 | 392 | 51 | 222 |

| DN500 | 20″ | 340 | 441 | 57 | 229 |

| DN600 | 24″ | 396 | 500 | 70 | 267 |

| DN700 | 28″ | 496 | 567 | 66 | 292 |

| DN800 | 32″ | 543 | 641 | 66 | 318 |

| DN900 | 36″ | 584 | 692 | 118 | 330 |

| DN1000 | 40″ | 638 | 735 | 142 | 410 |

| DN1200 | 44″ | 763 | 917 | 150 | 470 |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.