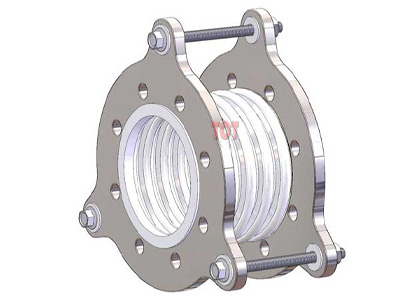

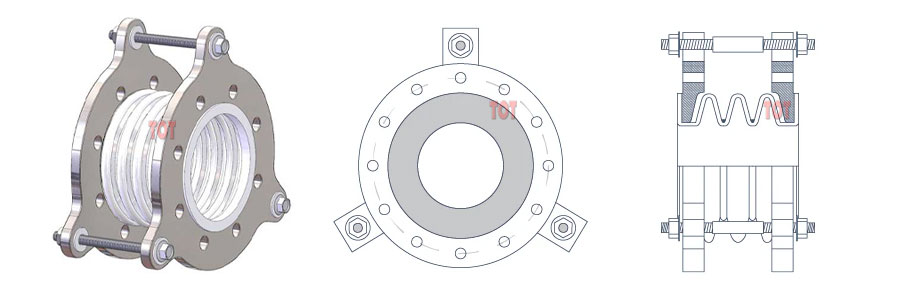

PTFE Expansion Joints

100% Corrosion-Proof Flexibility for Critical Process Piping

When your pipeline transports aggressive chemicals or ultra-pure media, you can’t afford leaks, corrosion, or performance loss. Our PTFE expansion joints give you uncompromising chemical resistance, reliable flexibility, and leak-free operation—engineered specifically for the world’s most demanding industries.

Our 100% PTFE expansion joints are worldwide trusted in the most critical and corrosive applications.

Description

PTFE expansion joints also known as PTFE bellows or Teflon compensators, are fully fabricated from virgin PTFE and designed to compensate for thermal expansion, vibration, and misalignment in corrosive fluid systems.

Unlike rubber-lined or metal joints, this all-PTFE solution offers complete immunity to nearly all chemicals, from concentrated acids and alkalis to solvents and ultra-pure water. Whether you’re operating in a chemical plant, pharmaceutical cleanroom, or semiconductor facility, this is your go-to solution for corrosion-proof reliability.

TOT Valve As a professional expansion joint manufacturer and supplier, can provide you with a variety of different types and sizes of PTFE expansion joints, and can also provide customized services according to your special needs.

Ready to protect your high-purity or chemical pipeline from stress and corrosion? Contact us now, our PTFE expansion joints are your ideal solution for long-term corrosion protection and pipeline flexibility.

PTFE Expansion Joint Features

100% PTFE Construction – No metal or rubber contact with media

Universal Chemical Resistance – Handles nearly all acids, bases, solvents

Low Permeability & High Purity – Suitable for food-grade, pharma, and ultrapure systems

High Flexibility – Compensates for axial, lateral, and angular movements

Thermal & Mechanical Stability – Withstands temperatures up to 200°C

Non-stick Surface – Prevents media buildup and reduces cleaning frequency

Vacuum Resistant Options – For sensitive or high-suction pipelines

PTFE Expansion Joint Materials & Construction

| Component | Material |

|---|---|

| Bellows | Virgin PTFE (Teflon) |

| Flanges (if applicable) | SS304, SS316 |

| Reinforcement (optional) | PTFE with embedded stainless rings or fiber |

*Note: All wetted parts are made from PTFE. Optional static grounding or vacuum support rings available.

Technical Parameters & Performance

Standard Types: Molded PTFE Bellows

Size Range (DN): DN25 to DN600

Temperature Range: –50°C to +200°C

Axial Compression/Extension: ±10 to ±30 mm

Lateral Movement: ±5 to ±20 mm

Angular Deflection: Up to 10°

Multi-standard designs: Flanged or fixed ends (DIN / ANSI / JIS)

PTFE Expansion Joint Dimensions

| Size | Quantity of Ripple | Pressure Grade(Mpa) | Available Area of Corugated Tube | Maximum Extemal Diameter(mm) | Length | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.6 | 1 | 1.6 | 2.5 | |||||||

| DN | Inch | Axial Compensation Length mm/ Toungness N/mm | Flange JZ/F | Connection JZ/J | ||||||

| 32 | 1-1/4″ | 8 | 22/26 | 20/26 | 18/63 | 15/90 | 16 | 225 | 160/250 | 264/280 |

| 40 | 1-1/2″ | 8 | 22/44 | 20/44 | 18/89 | 15/98 | 23 | 244 | 164/259 | 269/289 |

| 50 | 2″ | 8 | 22/51 | 20/70 | 18/70 | 15/106 | 37 | 259 | 172/276 | 282/306 |

| 65 | 2-1/2″ | 8 | 30/35 | 26/44 | 22/55 | 15/138 | 55 | 270 | 215/294 | 300/322 |

| 80 | 3″ | 8 | 36/26 | 34/33 | 28/41 | 19/68 | 81 | 284 | 240/338 | 344/366 |

| 100 | 4″ | 6 | 45/60 | 40/75 | 35/93 | 25/54 | 121 | 304 | 235/317 | 323/345 |

| 125 | 5″ | 5 | 42/47 | 38/59 | 34/74 | 29/117 | 180 | 334 | 282/314 | 316/342 |

| 150 | 6″ | 8 | 71/43 | 64/51 | 54/59 | 50/56 | 257 | 364 | 356/399 | 402/427 |

| 200 | 8″ | 6 | 65/44 | 59/52 | 53/58 | 48/78 | 479 | 442 | 340/402 | 402/426 |

| 250 | 10″ | 4 | 65/34 | 59/42 | 52/45 | 47/55 | 769 | 507 | 315/379 | 415/379 |

| 6 | 97/21 | 87/35 | 79/39 | 71/47 | 393/459 | 493/399 | ||||

| 300 | 12″ | 4 | 65/55 | 59/59 | 52/65 | 47/55 | 1105 | 562 | 366/427 | 466/467 |

| 6 | 97/35 | 87/37 | 79/41 | 71/457 | 464/525 | 564/565 | ||||

| 350 | 14″ | 4 | 65/62 | 59/67 | 52/74 | 47/81 | 1307 | 622 | 397/452 | 497/492 |

| 6 | 97/41 | 87/44 | 79/48 | 71/47 | 509/564 | 609/604 | ||||

| 400 | 16″ | 6 | 65/58 | 59/62 | 52/68 | 47/75 | 1611 | 340 | 412/478 | 512/518 |

| 8 | 97/39 | 87/43 | 79/47 | 71/52 | 420 | 522/588 | 622/628 | |||

| 450 | 18″ | 6 | 97/35 | 87/37 | 79/41 | 71/45 | 1972 | 340 | 403/498 | 503/523 |

| 8 | 145/22 | 131/23 | 118/35 | 108/28 | 450 | 503/658 | 603/648 | |||

| 500 | 20″ | 6 | 97/64 | 87/68 | 79/75 | 71/82 | 2445 | 340 | 431/523 | 531/554 |

| 8 | 145/37 | 131/39 | 118/43 | 106/48 | 450 | 531/665 | 631/742 | |||

| 600 | 24″ | 6 | 97/80 | 87/85 | 79/94 | 71/103 | 3534 | 380 | 478/548 | 578/588 |

| 8 | 145/45 | 131/49 | 118/53 | 106/60 | 500 | 658/679 | 758/781 | |||

*Custom sizes and movement ranges are available upon request.

Where PTFE Expansion Joints Are Used?

You should choose PTFE expansion joints whenever your application involves high corrosion risk, ultra-pure fluids, or extreme operating conditions. They are widely used in:

- Chemical Processing – Chlorine, HCl, H₂SO₄, HF, and nitric acid lines

- Pharmaceutical Manufacturing – Cleanroom fluid handling and CIP/SIP loops

- Semiconductor Plants – Ultrapure water, acids, solvents

- Food & Beverage – FDA-compliant, non-contaminating joints

- Laboratory Systems – Pure reagent and gas handling

- Pulp & Paper – Chlorine dioxide and bleaching media

- Water Treatment – High-concentration chemical dosing lines

FAQ

Is this different from a PTFE-lined rubber joint?

Yes. PTFE-lined rubber joints have a rubber body with a PTFE inner layer, while PTFE expansion joints are made entirely of PTFE, offering full chemical resistance and no risk of delamination or permeation.

Can PTFE expansion joints handle vacuum or suction?

Yes. We offer vacuum-resistant models with internal support rings or special convolutions to handle negative pressure.

Are they safe for pharmaceutical or food applications?

Absolutely. We use FDA-approved virgin PTFE, and options are available with USP Class VI certification.

What kind of flange connections can I choose?

ANSI, DIN, and JIS flange standards are all available. We can also provide PTFE-coated or fully encapsulated flanges depending on your requirements.

Can I get custom sizes or lengths?

Yes, we offer custom face-to-face lengths and non-standard geometries for special installations.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.