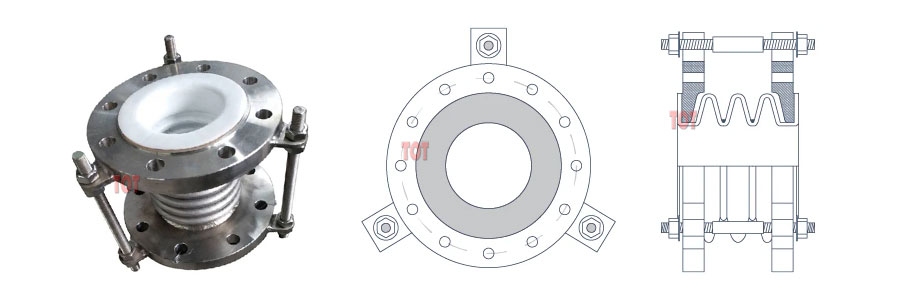

PTFE Lined Metal Expansion Joint

Built for Corrosion. Backed by Strength. Engineered for Movement.

When your pipeline transports aggressive chemicals under pressure and heat, standard expansion joints simply won’t last. You need a solution that combines the structural integrity of stainless steel with the chemical inertness of PTFE. Our PTFE lined metal expansion joints are purpose-built for this task, delivering uncompromising durability, flexibility, and chemical resistance in one compact unit.

Request a Quote Today! Let’s build the perfect expansion joint for your system.

Description

A PTFE lined metal expansion joint is a flexible connector that absorbs pipe system movement while resisting extreme corrosion.

The PTFE metal expansion joints provided by TOT are all made of high-quality raw materials. The metal bellows body is usually made of high-quality stainless steel or alloy steel, and the lined sleeve is made of extruded seamless pure PTFE.

This design allows the joint to flex under thermal expansion, mechanical vibration, or misalignment—while keeping aggressive chemicals, acids, and solvents away from the metal components.

Our PTFE-lined metal expansion joints will be your preferred solution in chemical plants, pharmaceutical processing plants, pulp and paper mills, and water treatment plants, avoiding downtime and reducing maintenance costs due to corrosive fluids in these facilities.

TOT As a professional expansion joint manufacturer and supplier, can provide you with a variety of different types and sizes of PTFE lined expansion joints, and can also provide customized services according to your special needs.

Contact us now, our PTFE lined metal expansion joints are your ideal solution for long-term corrosion protection and pipeline flexibility.

PTFE Lined Metal Expansion Joint Features

- 100% Virgin PTFE Lining: Chemically inert and non-stick

- Flexible Metal Bellows: Absorbs axial, lateral, and angular movement

- Corrosion-Resistant Design: Prevents media contact with metal

- High Pressure & Temperature Ratings: Suitable for demanding environments

- Vacuum Capable: Handles both pressure and negative pressure conditions

- Available in ANSI, DIN, JIS Flanges: Fully customizable to your system

- Optional External Covers or Limit Rods: For safety and enhanced performance

- Available designs include: Universal joints, hinged, hingedpinned and slotted, and gimbal types.

Main Components & Materials

| Component | Material Options |

|---|---|

| Bellows Body | Stainless Steel 304 / 316L / Inconel / Hastelloy |

| PTFE Liner | Virgin PTFE / Modified PTFE (Anti-static option) |

| Flanges | SS304 / SS316 / Galvanized Steel |

| Pull Rods / Covers | Galvanized / Painted Carbon Steel / Stainless |

| Vacuum Support Rings | SS304 / SS316 (optional for full vacuum service) |

PTFE Lined Metal Expansion Joint Specifications & Dimensions

| Nominal Diameter | Bellows Inside Diameter (in) | Metal Bellows Wall (in) | PTFE Liner Thickness (in) | Flare Face (in) | Flange Outside Diameter (in) | Flange Thickness (in) |

|---|---|---|---|---|---|---|

| 1-1/2 | 1.812 | 0.016 | 0.090 | 2875 | 5 | 11⁄16 |

| 2 | 2.312 | 0.018 | 0.095 | 3.625 | 6 | 3/4 |

| 3 | 3.312 | 0.024 | 0.100 | 5 | 7.5 | 15⁄16 |

| 4 | 4.25 | 0.024 | 0.110 | 6.187 | 9 | 15⁄16 |

| 6 | 6.062 | 0.036 | 0.120 | 8.5 | 11 | 1 |

| 8 | 8 | 0.042 | 0.131 | 10.0.625 | 13.5 | 1-1⁄8 |

| 10 | 10 | 0.048 | 0.141 | 12.75 | 16 | 1-3⁄16 |

| 12 | 11.937 | 0.060 | 0.152 | 15 | 19 | 1-1/4 |

| 14 | 13.125 | 0.072 | 0.160 | 16.25 | 21 | 1-3⁄8 |

| 16 | 15 | 0.072 | 0.175 | 18.5 | 23.5 | 1-7⁄16 |

| 18 | 16.875 | 0.072 | 0.191 | 21 | 25 | 1-9⁄16 |

| 20 | 18.812 | 0.072 | 0.198 | 23 | 27 | 1-11⁄16 |

| 24 | 22.625 | 0.072 | 0.222 | 27.25 | 32 | 1-7⁄8 |

*Note: Dimensions shown are for 150 Class Flanges per ASME B16.5

Where You’ll Need It Most?

PTFE lined metal expansion joints are ideal for high-risk, high-value, or high-corrosion environments. You’ll benefit most from these in:

- Chemical Processing Plants: Handles sulfuric acid, HCl, HF, caustic soda, chlorine, nitric acid, etc.

- Pharmaceutical Manufacturing: Ideal for clean-in-place (CIP), steam-in-place (SIP), and high-purity lines

- Desalination and Water Treatment: Resists scale inhibitors, brine, chlorine, and ozone

- Oil & Gas Refining (Amine Systems, Sulfur Recovery): Prevents failure in acidic gas or solvent-rich streams

- Pulp & Paper Mills: Withstands bleach, acid, and hot water media

- Mining and Smelting: For leaching and chemical slurry pipelines

FAQ

What’s the difference between PTFE lined metal joints and rubber-lined ones?

Rubber-lined joints are cost-effective but degrade under harsh chemicals. PTFE-lined metal joints resist nearly all corrosive fluids and maintain structural integrity under pressure and temperature.

Can it handle both vacuum and pressure?

Yes, vacuum-resistant designs with internal support rings are available. These joints are often used in vacuum scrubbers and solvent recovery systems.

Is the PTFE liner seamless?

Yes, our PTFE liners are seamless and extruded for maximum strength, with options for welded constructions in large diameters.

Can get FDA or anti-static versions?

Yes, we offer FDA-compliant PTFE and conductive (carbon-filled) PTFE liners for static-sensitive or hygienic applications.

What flange options do you offer?

ANSI, DIN, and JIS flange standards are available. We also offer PTFE-coated flanges for full corrosion isolation.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.