Resilient Seated Knife Gate Valve

When you need bubble-tight sealing performance in demanding flow applications, a resilient seated knife gate valve delivers uncompromising shut-off reliability. This advanced stainless steel resilient seated knife gate valve is engineered for applications requiring zero leakage — whether you’re handling clean water systems, slurry pipelines, or chemical processes where environmental compliance is critical. The premium resilient seat technology ensures positive sealing even with slight gate imperfections or thermal cycling, while maintaining the superior cutting action of our proven knife gate design. With flexible seat materials and robust construction, it provides leak-proof performance in the most demanding industrial environments.

Ready to achieve zero-leakage performance in your critical systems? Contact us today for a resilient seated solution engineered for your specific sealing requirements. Let TOT Valve secure your operations with guaranteed tight shut-off.

The TOT Valve You Can Depend On – Bubble-Tight Sealing When Zero Leakage Matters

When your process demands absolute sealing integrity for environmental protection, process control, or regulatory compliance, you need the superior sealing performance of our resilient seated knife gate valve. With advanced elastomeric seat technology, this knife gate valve provides guaranteed bubble-tight shut-off, superior flexibility for thermal cycling, and exceptional sealing even with gate wear — all while maintaining the reliable cutting action that makes knife gates ideal for challenging media.

The resilient seat design compensates for gate surface irregularities and provides consistent sealing performance throughout the valve’s service life, making it the preferred choice for critical sealing applications.

Why Resilient Seated Knife Gate Valve Works for You?

- Advanced resilient seat technology guarantees bubble-tight shut-off per MSS SP-81 Class VI standards.

- Multiple elastomer options (EPDM, NBR, Viton, PTFE) for specific chemical compatibility.

- Self-energizing seat design maintains sealing force as system pressure increases.

- Thermal cycling resistance maintains seal integrity through temperature variations.

- Corrosion-resistant stainless steel (SS304/316L) ensures long-term performance in aggressive media.

- Knife-edge gate cuts through fibrous materials, settled solids, and viscous media without compromising seal.

- Replaceable seat cartridge allows field maintenance without valve removal from line.

- Bi-directional sealing provides tight shut-off regardless of flow direction.

- Low operating torque due to reduced friction between gate and resilient seat.

- Extended service life with seat material optimized for specific applications.

- Fire-safe backup sealing with optional metal seat behind resilient seat.

Resilient Seated Knife Gate Valve Main Technical Specifications & Performance

Bubble-Tight Sealing, Advanced Resilient Seat Technology, Knife Gate Valve

| Specification | Details |

|---|---|

| Design & Manufacturing Standard | MSS SP-81, AWWA C515 |

| Size Range | DN50 to DN1200 mm; NPS 2″-48″ (Customized to Your Request) |

| Pressure Ratings | PN6, PN10, PN16, ANSI 150Psi, 5K/10K, etc. |

| Working Pressure Classification | DN50–DN300: 16Bar; DN350–DN500: 10Bar; DN600–DN800: 6Bar; DN900–DN1200: 4Bar |

| Leakage Performance | Zero leakage per MSS SP-81 Class VI (≤0.1 ml/min/inch diameter) |

| Face-to-Face Standard | MSS SP-81, AWWA C515 |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Seat Testing Standard | MSS SP-81, API 598, EN 12266-1 |

| Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature Range | -20°C to +120°C (EPDM), -40°C to +200°C (Viton), depending on seat material |

| Seat Materials | EPDM, NBR, FKM (Viton), PTFE, HNBR |

| Temperature–Pressure Rating Standards | GB/T12224–2007, ASME B16.34–2009, ISO7005–1 |

| Applications | Water Treatment, Chemical Processing, Food & Beverage, Pharmaceutical, Pulp & Paper, Mining, Power Generation, HVAC Systems |

| Actuation Methods | Manual, Pneumatic, Electric, Gear Drive, Chain Drive |

Resilient Seated Knife Gate Valve Main Components and Materials

| Part Name | Material Options | ||

|---|---|---|---|

| WCB | CF8 | CF8M | |

| Body | WCB | CF8 | CF8M |

| Gate | 304 | 316 | 316L |

| Resilient Seat | EPDM/NBR/Viton | EPDM/NBR/Viton | EPDM/Viton/PTFE |

| Seat Retainer | 304 SS | 316 SS | 316L SS |

| Backup Ring | PTFE | PTFE | PTFE |

| O-ring | NBR | NBR/EPDM | EPDM/Viton |

| Bonnet | WCB | CF8 | CF8M |

| Packing | PTFE | PTFE | PTFE |

| Packing Gland | WCB | CF8 | CF8M |

| Yoke | Q235 | 304 | 316 |

| Stem | 2Cr13 | 316 | 316L |

| Stem Nut | Bronze | Bronze | Bronze |

| Thrust Bearing | PTFE/SS | PTFE/SS | PTFE/SS |

| Handwheel | GGG30 | GGG30 | GGG30 |

| Stem Protector | 304 | 304 | 316 |

| Seat Spring | 301 SS | 316 SS | 316 SS |

| Fasteners | A193-B7 | A4-70 | A4-80 |

Advanced Resilient Seat Technology

Self-Energizing Design: System pressure assists seat sealing force for improved performance

Multiple Durometer Options: Shore A 70-90 hardness range for specific application requirements

Chemical Resistance Matrix: Comprehensive compatibility charts for seat material selection

Temperature Compensation: Seat design maintains sealing force across operating temperature range

Wear Resistance: Advanced compounds resist abrasion and extend service life

FDA Compliance: Food-grade seat materials available for sanitary applications

TOT Valve Tailored for Your Critical Sealing Applications – Premium Seat Options

You can customize this resilient seated valve for your exact sealing requirements:

Seat Materials:

- EPDM: General service, water applications, -20°C to +120°C

- NBR (Nitrile): Oil resistance, fuel systems, -40°C to +100°C

- FKM (Viton): Chemical resistance, high temperature, -26°C to +200°C

- PTFE: Universal chemical resistance, -200°C to +260°C

- HNBR: Enhanced oil/chemical resistance, -40°C to +150°C

Seat Configurations:

- Single resilient seat: Standard configuration for most applications

- Dual seat system: Resilient primary + metal backup for fire-safe service

- Cartridge seat: Field-replaceable seat assembly for easy maintenance

- Energized seat: Spring-loaded for enhanced sealing force

Special Features:

- Position indicators: Visual/electrical feedback for valve position

- Seat leak detection: Pressure taps for monitoring seat integrity

- Fire-safe design: Metal backup sealing per API 607

- Cryogenic service: Special seat materials for low-temperature applications

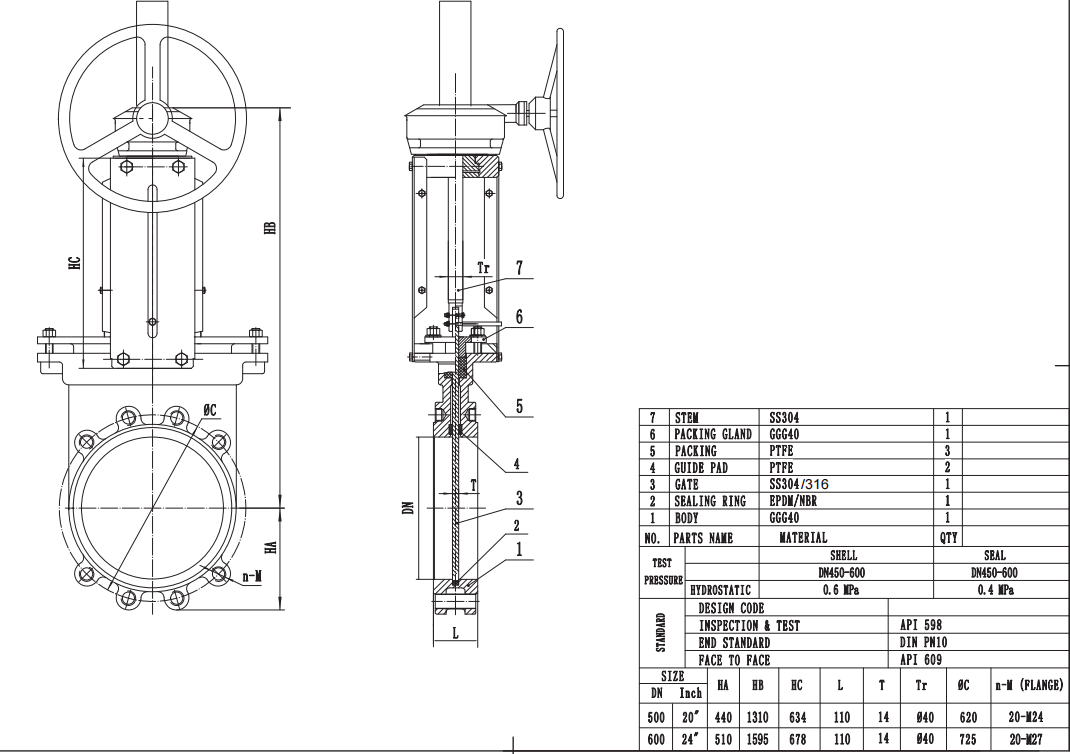

Resilient Seated Knife Gate Valve Dimensions

TOT valve can provide you with various sizes of resilient seated knife gate valve. We have listed some resilient seated knife gate valve sizes for PN16 for your reference.

If you don’t have the resilient seated knife gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | Seat Type | Max ΔP (Bar) |

|---|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | NPS(in) | |||||||||

| 50 | 2″ | 48 | 135 | 106 | 100 | 129 | 85 | 180 | 395 | EPDM |

| 65 | 2-1/2″ | 48 | 155 | 106 | 115 | 147 | 85 | 180 | 436 | EPDM |

| 80 | 3″ | 51 | 175 | 106 | 121 | 168 | 85 | 200 | 478 | EPDM |

| 100 | 4″ | 51 | 163 | 106 | 138 | 192 | 85 | 200 | 545 | EPDM |

| 125 | 5″ | 57 | 192 | 120 | 160 | 215 | 87 | 250 | 630 | EPDM/NBR |

| 150 | 6″ | 57 | 216 | 130 | 185 | 245 | 87 | 280 | 705 | EPDM/NBR |

| 200 | 8″ | 70 | 271 | 130 | 235 | 302 | 105 | 300 | 850 | EPDM/Viton |

| 250 | 10″ | 70 | 335 | 140 | 300 | 355 | 105 | 350 | 1065 | EPDM/Viton |

| 300 | 12″ | 76 | 381 | 160 | 350 | 401 | 105 | 400 | 1200 | EPDM/Viton |

| 350 | 14″ | 76 | 436 | 180 | 400 | 465 | 117 | 450 | 1375 | EPDM/Viton |

| 400 | 16″ | 89 | 505 | 180 | 455 | 511 | 117 | 450 | 1525 | Viton/PTFE |

Seat Material Selection Guide

| Application | Recommended Seat | Temperature Range | Key Benefits |

|---|---|---|---|

| Potable Water | EPDM | -20°C to +80°C | FDA approved, taste/odor free |

| Wastewater | EPDM/NBR | -20°C to +80°C | Excellent abrasion resistance |

| Chemical Process | Viton/PTFE | -26°C to +200°C | Broad chemical compatibility |

| Food & Beverage | EPDM (FDA) | -10°C to +100°C | Sanitary design, easy cleaning |

| Petroleum Products | NBR/Viton | -40°C to +120°C | Hydrocarbon resistance |

| High Temperature | Viton/PTFE | Up to +200°C | Thermal stability |

| Cryogenic Service | PTFE | -200°C to +260°C | Low temperature flexibility |

Performance Advantages & Testing

Zero Leakage Guarantee: Meets or exceeds MSS SP-81 Class VI leakage requirements

Extended Cycling Life: Tested to 10,000+ cycles while maintaining seal integrity

Pressure Cycling Resistance: Maintains sealing through repeated pressure variations

Thermal Shock Testing: Validated performance through rapid temperature changes

Chemical Compatibility: Comprehensive testing with process media

Abrasion Resistance: Specialized testing for slurry and particle-laden media

Quality Assurance & Certification

Every TOT resilient seated knife gate valve undergoes rigorous testing:

- Hydrostatic shell testing at 1.5x working pressure

- Seat leakage testing per MSS SP-81 Class VI standards

- Resilient seat durability testing including cycling and aging tests

- Chemical compatibility verification for seat material applications

- Temperature cycling tests to verify thermal performance

- Material certification with full traceability documentation

Installation & Maintenance Benefits

Easy Installation: No special tools required for seat replacement

Field Serviceability: Seat cartridge replacement without valve removal

Predictive Maintenance: Seat wear indicators for planned replacement

Reduced Inventory: Common seat designs across valve sizes

Training Support: Comprehensive maintenance training programs available

Technical Documentation: Detailed seat selection and maintenance guides provided

Environmental & Regulatory Compliance

Zero Fugitive Emissions: Meets EPA and international environmental standards

Drinking Water Safe: NSF/ANSI 61 certified seat materials available

Food Contact Safe: FDA-compliant elastomers for food processing

Fire Safety: Optional fire-safe backup sealing systems

Pressure Equipment Directive: CE marked for European compliance

Quality Standards: ISO 9001 certified manufacturing processes

Contact TOT Valve today for technical consultation and competitive quotation on your resilient seated knife gate valve requirements for critical sealing applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.