Through Conduit Knife Gate Valve

You are looking for a heavy-duty, bi-directional knife gate valve designed for demanding applications such as pulp discharge, silo outlets and chemical loading. Our through conduit knife gate valve features a two-piece body, no stagnant area and a gate movement similar to a “cigar cutter” to provide clean shutoff, zero product accumulation and full bore flow even in processes with high impurity content such as recycled pulp.

TOT Valve complies with international standards and is tested to EN and ISO standards to ensure safety, performance and reliability in your real-world application.

Whether you need 1 or 100 pieces, we can deliver tested and qualified performance products on time.

Description

If you are handling pulp, recycled paper or slurries with solid contaminants such as short fibers or fibers, then the through conduit knife gate valve is a solution you can trust. The valve has a no stagnation zone design to ensure bi-directional sealing and zero product accumulation even in harsh, high-impact environments.

You’ll benefit from a two-piece bolted body, longer gate and dual packing system, and a through-hole design that allows full flow when open and full shutoff when closed. Ideal for pulp outlets, silo unloading, and chemical loading and unloading systems, this valve delivers clean operation, very low maintenance, and tight shutoff under pressure – exactly what your process demands.

Core Advantages at a Glance

| Feature | Your Advantage |

| Full Bore Flow Path | No pressure drop, no turbulence, ideal for slurry and fibers |

| Gate with O-ported or V-notch | Precise shut-off even in partially open conditions |

| Dual Resilient or Metal Seats | Tight shut-off in both directions, even under fluctuating pressure |

| Self-cleaning Design | Flush ports eliminate accumulation of solids in seat area |

| Replaceable Wear Components | Seats, gate, and packing can be easily maintained or replaced onsite |

| Custom Automation Options | Pneumatic, electric, or hydraulic actuators with smart position feedback |

| Heavy-duty Bonnet Options | For high pressure, sub-zero, or vacuum conditions |

Main Technical Parameters & Performance

| Bi-directional sealing, floating seat, flow guiding hole, dual packing design, integral wafer type ultra-thin structure knife gate valve. | |

| Design Standard | MSS SP-81 |

| Size Range | DN50–DN600 |

| Pressure Rating | PN10, PN16, ANSI 150Psi, 5K/10K |

| Rated Working Pressure | DN50~DN250: 10Bar DN300~DN450: 7Bar, DN500~DN600: 4Bar |

| Structure Length Standard | MSS SP-81 |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Valve Test Standard | MSS SP–81 |

| Valve Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature & Pressure Testing Standards | GB/T12224–2005, GB/T 21634–2009, ISO7005–1 |

| Applicable Industries | Pulp and paper, mining, metallurgy, pharmaceuticals, food, wastewater treatment, municipal sewage, water conservancy, etc. |

| Actuation Modes | Manual, pneumatic, electric, gear, chain wheel drive |

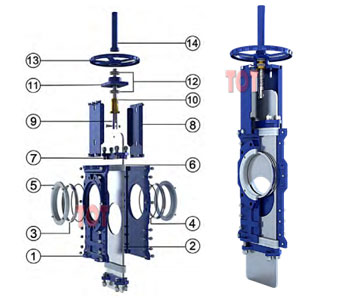

Through Conduit Knife Gate Valve Main Components and Materials

| Material Configuration | |||

|---|---|---|---|

| Part | WCB | CF8 | CE8M |

| Body | WCB | CF8 | CF8M |

| Disc | 20Cr13+Cr | 20Cr13+Cr | 2205+Cr |

| Seat | STL or EPDM | ||

| O-Ring | NBR | ||

| Seat Cover | WCB | CF8 | CF8M |

| Packing | PTFE | ||

| Gland | WCB | CF8 | CF8M |

| Bracket | Q235 | 304 | 304 |

| Stem | 2Cr13 | 2Cr13 | 2Cr13 |

| Stem Nut | Brass | Brass | Brass |

| Bearing | 65Mn | 65Mn | 65Mn |

| Support Base | WCB | WCB | WCB |

| Handwheel | GGG30 (Epoxy Coated) | ||

| Stem Protector | 304 | 304 | 304 |

| Fasteners | A2-70 | A2-70 | A4-70 |

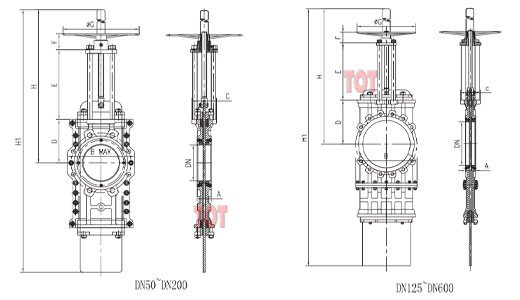

Through Conduit Knife Gate Valve Dimensions

TOT valve can provide you with various sizes of through conduit knife gate valve. We have listed some through conduit type knife gate valve sizes for PN16 for your reference.

If you don’t have the through conduit type knife gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A | B | C | D | E | F | G | H | H1 | Cylinder Size | Air Inlet Size | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | |||||||||||

| 50 | 2″ | 48 | 140 | 106 | 100 | 129 | 230 | 100 | 475 | 665 | C100/60 | F1/4 |

| 65 | 2-1/2″ | 48 | 175 | 106 | 135 | 147 | 245 | 100 | 540 | 895 | C100/75 | F1/4 |

| 80 | 3″ | 51 | 185 | 106 | 145 | 168 | 270 | 120 | 570 | 915 | C125/85 | F1/4 |

| 100 | 4″ | 51 | 220 | 106 | 150 | 192 | 300 | 120 | 605 | 925 | C125/110 | F1/4 |

| 125 | 5″ | 57 | 195 | 120 | 170 | 215 | 330 | 150 | 620 | 940 | C160/135 | F3/8 |

| 150 | 6″ | 57 | 225 | 130 | 175 | 245 | 350 | 150 | 775 | 1220 | C160/160 | F3/8 |

| 200 | 8″ | 70 | 280 | 130 | 215 | 302 | 440 | 195 | 950 | 1510 | C200/210 | F3/8 |

| 250 | 10″ | 70 | 356 | 140 | 270 | 355 | 505 | 240 | 1165 | 1875 | C250/260 | F3/8 |

| 300 | 12″ | 76 | 405 | 160 | 310 | 401 | 550 | 280 | 1285 | 2110 | C300/310 | F3/8 |

| 350 | 14″ | 76 | 480 | 180 | 330 | 465 | 620 | 380 | 1385 | 2330 | C300/360 | F3/8 |

| 400 | 16″ | 89 | 530 | 180 | 375 | 511 | 670 | 395 | 1530 | 2600 | C320/410 | F3/8 |

| 450 | 18″ | 89 | 610 | 240 | 420 | 580 | 710 | 395 | 1780 | 2965 | C320/460 | F3/8 |

| 500 | 20″ | 114 | 650 | 270 | 465 | 640 | 800 | 425 | 1915 | 3265 | C350/510 | F3/8 |

| 600 | 24″ | 114 | 805 | 270 | 500 | 740 | 910 | 425 | 2190 | 3860 | C350/610 | F3/8 |

Applications That Require High Reliability

This valve is ideal for isolation in your demanding applications where downtime is costly:

Pulp and Paper: Bleaching lines, stock preparation, black liquor isolation for high consistency pulp (≥ 12%), through conduit knife gate valve design effectively prevents fiber plugging and scaling

Mining and Mineral Processing: Full bore design eliminates attack from tailings, slurries containing sand, gravel or metal fines, acidic leachate, lime slurry or abrasive concentrate

Wastewater and Sludge Systems: Thickening sludge, grit chambers, backwash circuits, prevent horizontal pipe plugging

Power Generation (Thermoelectric/Biomass): Metal-to-metal seats withstand extreme temperatures for fly ash handling, gypsum slurries and bottom ash

Chemical and Petrochemical: Corrosive or high pH fluids, optional alloy construction for HCl, H₂SO₄ or NaOH applications

FAQ

How does through conduit knife gate valve avoid seat clogging in fiber media?

A: The dual-seat design plus purge ports keeps the gate area clean. The O-port or rectangular blade prevents fiber wrapping or pressure jams.

What’s the lifespan of the valve in abrasive slurry?

A: With proper hard-facing and periodic maintenance, typical service life exceeds 3–5 years in mineral slurry.

Can through conduit knife gate valve be fully automated for remote control?

A: Yes, we offer pneumatic, electric, and hydraulic actuators with feedback signals (open/close/position) ready for DCS/PLC integration.

Is there a version for vacuum or backpressure?

A: Yes, bonneted and pressure-balanced versions are available for vacuum service or reverse pressure handling.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.