Table of Contents

Toggle📌 What is a Slide Gate Valve?

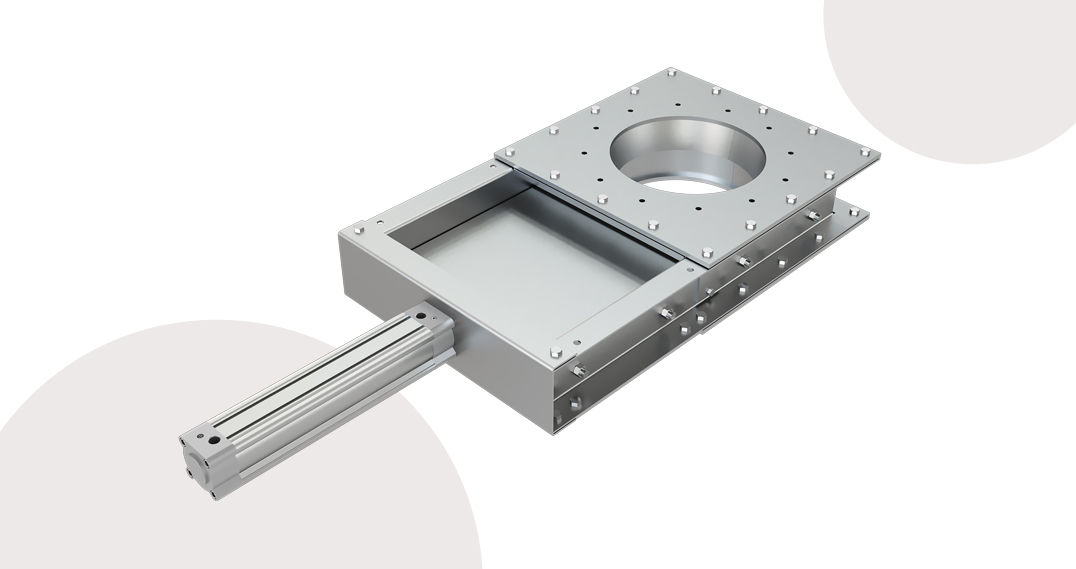

A slide gate valve is a type of shut-off valve used to control or isolate the flow of dry bulk materials, powders, granules, and sometimes liquids in industrial systems. The valve uses a sliding plate (or “gate”) that moves across the flow opening to start, stop, or throttle the material flow.

Unlike knife gate valves (used mostly for slurries and fluids), slide gate valves are commonly applied in gravity-fed systems, bins, silos, and conveyors.

⚙️ Key Features & Benefits

Simple Design – Sliding plate allows quick shut-off.

Durability – Made from carbon steel, stainless steel, or alloy materials for long service life.

Versatility – Suitable for powders, granules, pellets, and bulk solids.

Low Maintenance – Minimal moving parts reduce wear and downtime.

Customization – Available with manual, pneumatic, or electric actuation.

Space-Saving – Compact structure ideal for integration into bulk handling systems.

🏭 Common Applications

Slide gate valves are widely used in industries handling dry bulk materials and process flow:

Cement Plants – For clinker, limestone, fly ash.

Mining & Minerals – Handling ores, coal, and concentrates.

Agriculture & Feed Mills – Grain, soy, animal feed.

Food & Beverage – Sugar, flour, salt, coffee beans.

Chemical & Plastics – Powders, resins, plastic pellets.

Waste & Recycling – Ash, biomass, alternative fuels.

🔧 Types of Slide Gate Valves

Manual Slide Gate Valves – Handwheel or lever operated, best for small systems or occasional operation.

Pneumatic Slide Gate Valves – Air cylinders automate the opening/closing, ideal for fast process lines.

Electric Slide Gate Valves – Motorized operation for precise control and integration with PLCs.

Heavy-Duty Slide Gate Valves – Reinforced designs for abrasive bulk solids and high-cycle use.

📊 Technical Specifications (Typical)

| Parameter | Range / Options |

|---|---|

| Size Range | DN50 – DN1000 (2″ – 40″) |

| Materials | Cast Iron, Carbon Steel, Stainless Steel |

| Gate Material | Stainless Steel, Hardened Steel |

| Seal Options | Metal-to-Metal, EPDM, NBR, PTFE |

| Operation | Manual, Pneumatic, Electric |

| Applications | Bulk solids, powders, light slurry |

✅ Slide Gate Valve vs. Knife Gate Valve

Slide Gate Valve – Optimized for powders and bulk solids (gravity flow systems).

Knife Gate Valve – Designed for slurries, wastewater, pulp, and viscous fluids.

👉 Choosing the right valve depends on whether you’re handling solids or liquid/slurry media.

📩 Request a Quote

Looking for high-performance slide gate valves for your plant or material handling system?

We supply a wide range of manual, pneumatic, and electric slide gate valves tailored to your industry. Contact us today for datasheets, pricing, and technical support.