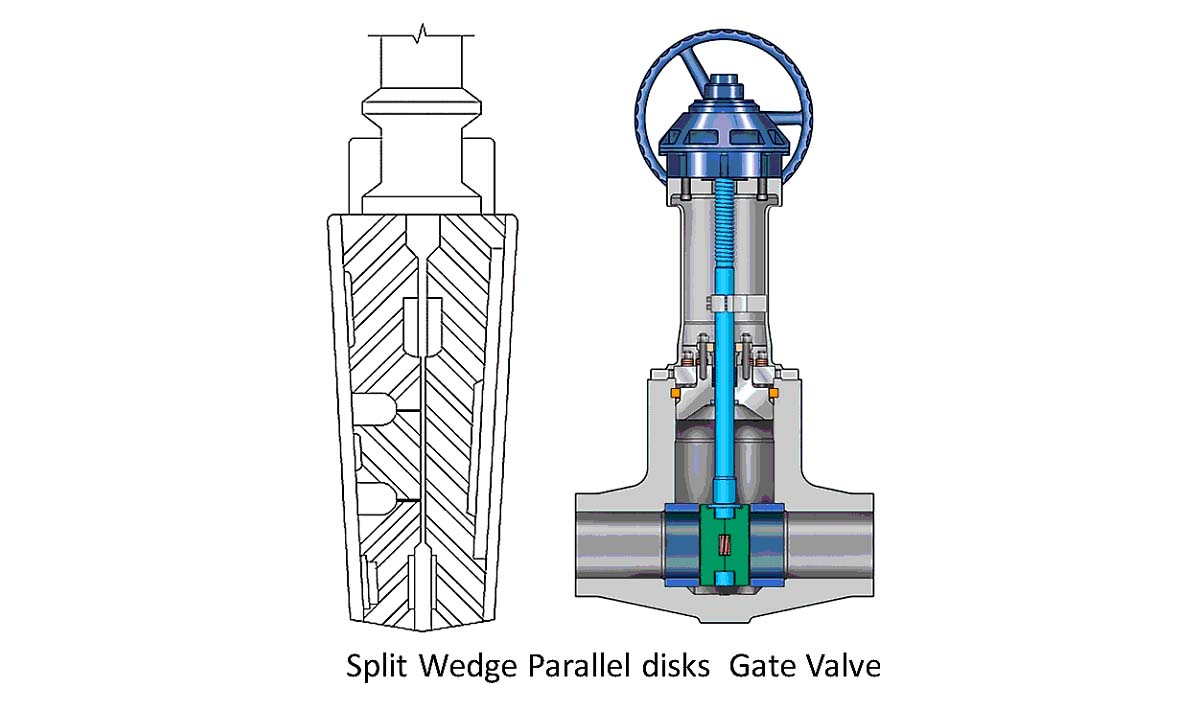

A split wedge gate valve, also known as a split disc gate valve, is a type of gate valve that uses a two-piece wedge assembly to provide improved sealing and flexibility in pipelines with temperature variations and alignment issues. Its ability to self-adjust under pressure makes it ideal for a wide range of medium- to high-pressure applications.

Table of Contents

Toggle🔧 What Is a Split Wedge Gate Valve?

Unlike the solid wedge, which consists of a single disc, a split wedge gate valve uses two separate discs that are held together by a hinge or spacer. This design allows the discs to move slightly and self-align with the seat surfaces, improving sealing even when the pipeline experiences thermal expansion, contraction, or slight seat misalignment.

🛠️ Key Features

Two-piece wedge disc connected by a hinge pin or spacer

Self-adjusting to seat misalignments and pressure fluctuations

Tight shutoff in both directions

Reduced seat wear compared to solid wedge designs

Reliable performance under high-temperature and high-pressure conditions

📌 Common Applications

Split wedge gate valves are used across a variety of demanding industries, especially where temperature fluctuations or slight piping misalignments are present:

Power plants (especially steam and high-temperature systems)

Petrochemical and oil & gas

Refineries

Pulp and paper industries

High-pressure steam systems

Process industries requiring tight shutoff and reduced seat wear

🧱 Materials of Construction

| Component | Common Materials |

|---|---|

| Body/Bonnet | Carbon steel, alloy steel, stainless steel |

| Wedge Discs | Forged steel, stainless steel, hard-faced alloys |

| Seats | Stainless steel, Monel, Stellite |

| Stem | Stainless steel, Cr-Mo alloy |

✅ Advantages of Split Wedge Gate Valves

Excellent seat alignment: Each half of the disc can conform to the seat independently

Less seat damage: Reduced risk of binding or galling

Ideal for high-temperature applications: Handles thermal expansion better than solid wedges

Improved tightness over time due to self-seating action

Better sealing in older or slightly worn valve bodies

⚠️ Limitations

More complex design than solid wedge valves, potentially higher maintenance

Hinge/spacer mechanism is a potential wear point

Not suitable for slurries or fluids with solids, as particles can get trapped between the discs

More expensive compared to solid wedge types

🔍 Split Wedge vs Solid Wedge vs Flexible Wedge

| Feature | Solid Wedge | Flexible Wedge | Split Wedge |

|---|---|---|---|

| Sealing Adjustment | Rigid | Some flexibility | High flexibility |

| Thermal Expansion | Poor | Good | Excellent |

| Misalignment Tolerance | Low | Moderate | High |

| Complexity | Low | Medium | High |

| Cost | Low | Moderate | Higher |

| Recommended Use | Clean, stable systems | Moderate conditions | High-temp/pressure systems |

🔚 Conclusion

The split wedge gate valve is a high-performance solution for industrial applications where tight shutoff, self-alignment, and temperature variability are critical concerns. Though more complex than solid or flexible wedges, it offers superior longevity, sealing performance, and operational reliability in challenging conditions.

When choosing the right gate valve, understanding the fluid type, pressure, temperature, and installation environment is essential. For dynamic systems with thermal changes or misalignment potential, the split wedge gate valve is often the best fit.