Table of Contents

ToggleWhat is a Plug Valve?

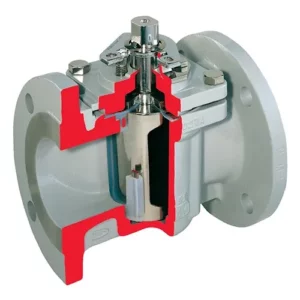

A plug valve is a type of quarter-turn valve that uses a cylindrical or tapered plug to control the flow of a fluid. By rotating the plug 90 degrees, the valve can be quickly opened or closed. Known for their simple design, minimal pressure drop, and swift operation, plug valves are widely used across various industries, including oil and gas, chemical processing, and water treatment.

How a Plug Valve Works

The principle behind a plug valve is straightforward. The core component is the plug, which has a passage drilled through it.

- Open Position: When the handle or actuator is turned, the passage in the plug aligns with the flow path of the body, allowing fluid to pass unimpeded. The valve is fully open, creating a straight flow path that minimizes pressure drop.

- Closed Position: When the plug is rotated 90 degrees, its solid side blocks the flow path, shutting off the fluid completely.

This simple quarter-turn mechanism allows for very fast operation, making it far superior to rising-stem valves like gate valves for applications that require quick on/off control.

Common Types of Plug Valves

Based on their design features, plug valves are primarily categorized as follows:

- By Sealing Method:

- Lubricated Plug Valves: These valves use a sealant or lubricant injected between the plug and the body to reduce friction, prevent corrosion, and enhance sealing. They are ideal for high-pressure applications or when handling dirty or abrasive fluids.

- Non-Lubricated Plug Valves: The plug in this type is typically coated with a non-metallic material like PTFE, providing a self-lubricating seal. They require less maintenance and are often used with clean or less-corrosive media.

- By Plug Shape:

- Tapered Plug Valves: The tapered plug provides a wedging action that improves sealing performance as the plug is seated.

- Cylindrical Plug Valves: This type has a cylindrical plug and is simpler in design.

- By Number of Ports:

- Two-Way Plug Valves: The most common type, used for basic on/off control.

- Multi-Port Plug Valves: These valves, such as three-way or four-way designs, can divert or mix fluid flow, making them useful in more complex piping systems.

Advantages and Disadvantages of Plug Valves

Understanding the pros and cons is crucial for selecting the right valve for a job.

- Advantages:

- Fast Operation: A 90-degree turn is all that’s needed to open or close the valve.

- Low Pressure Drop: The full-port design in the open position allows for an uninterrupted flow path.

- Simple Structure: With few moving parts, they are reliable and easy to maintain.

- Good for Slurries: The plug’s wiping action helps prevent solids from accumulating.

- Disadvantages:

- High Torque: Large or high-pressure valves can require significant force to operate.

- Poor Throttling: They are not well-suited for fine flow regulation and are primarily used for on/off service.

- Leakage Risk: Some types may develop leaks over time due to wear, especially if not properly maintained.

Plug Valve vs. Other Common Valves

- Plug Valve vs. Ball Valve: Both are quarter-turn valves. However, ball valves generally offer better sealing and easier operation. Plug valves are often preferred in applications with solid-containing media, as the plug can scrape away debris.

- Plug Valve vs. Gate Valve: Gate valves require linear motion, making them slower to operate and prone to higher pressure drop. The plug valve’s quarter-turn action and full-port design offer clear advantages in efficiency.

- Plug Valve vs. Butterfly Valve: While butterfly valves are lightweight and cost-effective, the plug valve provides a completely unobstructed flow path, leading to lower pressure loss.

Conclusion

The plug valve, with its simple yet robust design, is a highly effective tool for fluid control. While it’s not ideal for all applications, its fast operation, low pressure drop, and ability to handle challenging media make it a reliable choice for critical on/off services in many industries.