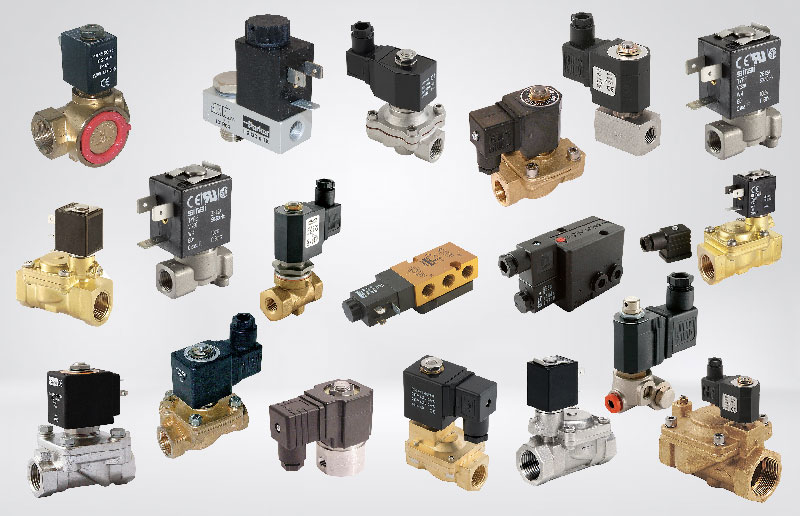

Solenoid valves represent one of the most versatile and widely deployed control elements in industrial automation, fluid power systems, and process control applications. These electromechanical devices convert electrical energy into mechanical motion to control the flow of liquids, gases, or steam through piping systems. Understanding the various types of solenoid valves and their operational characteristics is essential for engineers, maintenance personnel, and system designers seeking optimal performance in their specific applications.

Table of Contents

ToggleUnderstanding Solenoid Valve Fundamentals

At its core, a solenoid valve consists of two primary components: an electromagnetic solenoid coil and a valve body containing the flow control mechanism. When electrical current energizes the coil, it generates a magnetic field that actuates a plunger or armature, which in turn opens or closes the valve’s flow passage. This simple yet effective principle enables rapid response times, precise control, and reliable operation across countless industrial applications.

The beauty of solenoid valve technology lies in its adaptability. By varying the internal configuration, port arrangement, actuation method, and construction materials, manufacturers have developed numerous valve types optimized for specific operating conditions, fluid characteristics, and control requirements.

Classification by Number of Ports and Positions

One of the most fundamental ways to categorize solenoid valves is by their port configuration and operational positions. This classification directly determines how the valve can control fluid flow within a system.

Two-Way Solenoid Valves (2/2)

Two-way valves feature two ports—an inlet and an outlet—and operate in two positions: open or closed. These represent the simplest solenoid valve configuration and function essentially as on-off switches for fluid flow.

**Normally Closed (NC) Configuration:** In the de-energized state, the valve remains closed, blocking flow. When the solenoid energizes, it opens the passage, permitting flow. This configuration is ideal for applications requiring fail-safe closure, such as emergency shutdown systems or applications where maintaining flow cessation during power failures is critical.

**Normally Open (NO) Configuration:** The opposite arrangement keeps the valve open when de-energized and closes it upon energization. This design suits applications where maintaining flow during power interruptions is essential, or where energy conservation dictates minimizing the time the coil remains energized.

Two-way valves excel in simple start-stop control applications including water dispensing systems, irrigation control, chemical injection, and general-purpose fluid isolation. Their straightforward operation and cost-effectiveness make them the first choice when complex flow routing is unnecessary.

Three-Way Solenoid Valves (3/2)

Three-way valves incorporate three ports and two operational positions, enabling more sophisticated flow control strategies. The typical port arrangement includes a pressure port (inlet), a working port (outlet), and an exhaust or secondary outlet port.

These valves can divert flow between two different circuits or alternate between supplying and exhausting a downstream component. In pneumatic systems, three-way valves commonly control single-acting cylinders, where compressed air must both actuate the cylinder and then be exhausted to atmosphere for the return stroke.

The versatility of three-way valves makes them valuable in applications requiring flow diversion, such as mixing operations, alternating between two different supply sources, or controlling pneumatic actuators with spring return mechanisms.

Four-Way and Five-Way Solenoid Valves (4/2, 5/2, 5/3)

Four-way and five-way valves represent the most complex standard configurations, featuring multiple ports that enable sophisticated directional control. These valves predominate in pneumatic control systems, particularly for operating double-acting cylinders and rotary actuators.

**Four-Way Valves (4/2):** With four ports—typically designated as pressure, two working ports, and exhaust—these valves can reverse the direction of pneumatic actuators. When the solenoid energizes, pressurized air routes to one side of the cylinder while the opposite side exhausts. De-energizing reverses the flow paths.

**Five-Way Valves (5/2 and 5/3):** The addition of a fifth port provides separate exhaust paths for each working port, improving control precision and enabling faster actuator response. The 5/2 configuration offers two positions, while the 5/3 variant includes a neutral center position with various flow characteristics—ports may be closed, exhausted, or pressurized depending on the specific center condition design.

These multi-port valves are indispensable in automated manufacturing, robotics, material handling equipment, and any application requiring precise bidirectional control of pneumatic actuators.

Classification by Operating Principle

Beyond port configuration, solenoid valves differ fundamentally in how they achieve flow control, with operating principle significantly affecting performance characteristics, pressure requirements, and application suitability.

Direct-Acting Solenoid Valves

Direct-acting valves employ the electromagnetic force generated by the solenoid to directly lift the valve seal from its seat, opening the flow passage. The solenoid plunger mechanically connects to the sealing element, and coil energization immediately opens the valve.

This straightforward design offers several advantages. Direct-acting valves operate independently of system pressure—they function equally well from zero pressure upward. Response times are exceptionally fast, often measured in milliseconds. The simple mechanical arrangement enhances reliability and reduces maintenance requirements.

However, direct-acting operation imposes practical limitations. The electromagnetic force must overcome both the sealing force and any differential pressure across the valve. This requirement limits direct-acting valves to relatively small orifice sizes and moderate pressure ratings. Larger valves would require impractically large solenoids consuming excessive electrical power.

Direct-acting solenoid valves excel in applications with small flow requirements, where zero-pressure operation is necessary, or where ultra-fast response times are critical. Common applications include analytical instrumentation, medical devices, laboratory equipment, and precision dispensing systems.

Pilot-Operated Solenoid Valves

Pilot-operated valves leverage system pressure to assist in opening the main valve orifice, dramatically reducing the electromagnetic force requirements. These valves incorporate a small direct-acting pilot valve that controls pressure in a chamber above the main seal. When the pilot opens, it releases pressure from this chamber, allowing system pressure acting on the underside of the main seal to lift it and open the valve.

This pressure-assisted operation enables pilot-operated valves to control much larger flow passages with relatively small solenoids. They efficiently handle high flow rates and can operate at elevated pressures while consuming modest electrical power.

The trade-off comes in the form of minimum pressure requirements. Pilot-operated valves typically require a minimum differential pressure—often 0.5 bar or more—to function properly. Below this threshold, insufficient force exists to open the main valve. Additionally, response times are slightly slower than direct-acting valves due to the two-stage operation.

Pilot-operated solenoid valves dominate applications involving substantial flow rates, elevated pressures, or larger pipe sizes. They’re prevalent in industrial compressed air systems, steam control, water treatment plants, HVAC systems, and general industrial process control.

Semi-Direct Acting Solenoid Valves

Semi-direct acting valves represent a hybrid design that combines attributes of both direct and pilot-operated principles. Also called assisted-lift valves, these incorporate a pilot mechanism that reduces the force required to open the valve, while the solenoid still provides significant direct lifting force.

This configuration enables operation from zero pressure while handling somewhat larger orifices than pure direct-acting designs. Semi-direct acting valves bridge the performance gap, offering a compromise solution for medium flow applications that may occasionally encounter low-pressure conditions.

Classification by Valve Configuration

The internal mechanical arrangement of the sealing elements and flow passages represents another critical classification dimension, affecting performance characteristics, maintenance requirements, and application suitability.

Poppet Valves

Poppet-style solenoid valves employ a disc or conical sealing element that lifts perpendicular to the valve seat to permit flow. The poppet design achieves excellent sealing characteristics, with the sealing force increasing as differential pressure rises—a self-sealing effect that enhances reliability.

Poppet valves deliver bubble-tight shutoff even with contaminated fluids, as the sealing occurs along a relatively small circular line. This design tolerates reasonable amounts of particulate contamination without leakage. The robust sealing mechanism and simple construction contribute to long service life with minimal maintenance.

The perpendicular flow path through poppet valves creates higher pressure drops compared to some alternatives, but this rarely proves problematic in most applications. Poppet-style solenoid valves predominate in general industrial service where reliable shutoff and contamination tolerance are priorities.

Spool Valves

Spool-type solenoid valves utilize a cylindrical element that slides within a precision-machined bore, covering and uncovering ports as it moves. This configuration enables very low pressure drops and high flow capacities relative to valve size, making spool valves ideal for pneumatic systems and applications prioritizing flow efficiency.

The sliding action and straight-through flow paths minimize flow restriction, enabling compact valve designs with impressive flow coefficients. Spool valves typically offer very fast response times and handle high cycling frequencies without performance degradation.

However, spool valves demand cleaner operating environments. The tight clearances between spool and bore—necessary for adequate sealing—make these valves sensitive to particulate contamination. Suspended particles can cause scoring or jamming, necessitating proper filtration in critical applications. Regular maintenance including occasional lubrication may be required to ensure smooth operation.

Spool-type solenoid valves excel in pneumatic control applications, clean hydraulic systems, and situations where minimizing pressure drop is paramount.

Diaphragm Valves

Diaphragm solenoid valves employ a flexible diaphragm as the sealing element, which flexes to open or close the flow passage. The diaphragm isolates the solenoid mechanism from the process fluid, offering unique advantages in challenging applications.

This isolation protects the electrical components from corrosive, abrasive, or contaminated fluids, dramatically expanding material compatibility options. Diaphragm valves can handle highly corrosive chemicals, slurries, and fluids containing suspended solids that would damage other valve types. The flexible diaphragm accommodates particulates without permanent damage.

The diaphragm construction also eliminates sliding seals and minimizes crevices where fluid can stagnate, making these valves suitable for sanitary applications in food processing, pharmaceutical manufacturing, and biotechnology. Many diaphragm valves are designed for clean-in-place (CIP) sterilization procedures.

Limitations include moderate flow capacities due to the flexible nature of the sealing element and potential diaphragm fatigue with extremely high cycle frequencies. Regular diaphragm inspection and replacement constitutes a maintenance consideration.

Classification by Power Type and Control Method

The electrical characteristics of the solenoid coil and the control strategy represent important selection criteria affecting system design, energy consumption, and functional capabilities.

AC vs. DC Solenoids

**AC-powered solenoid valves** operate directly from standard line voltage (typically 110V, 120V, or 230V depending on region). They’re simple to integrate into systems, requiring no additional power supplies. AC solenoids deliver strong initial pull-in force due to the higher peak voltage, enabling rapid actuation.

However, AC solenoids consume more power and generate more heat during continuous operation. The alternating current creates mechanical vibration and audible humming, which may be undesirable in noise-sensitive environments. AC solenoids also require special coil designs to prevent excessive current draw after the plunger seats.

**DC-powered solenoid valves** operate on direct current, typically at voltages ranging from 12V to 48V. DC solenoids run cooler and more quietly than AC equivalents, with no vibration or hum. They consume less power during continuous operation, making them ideal for battery-powered applications or energy-conscious designs.

DC systems require appropriate power supplies to convert AC line voltage, adding component cost and complexity. DC solenoids may exhibit somewhat slower initial actuation due to lower available voltage, though proper coil design minimizes this difference.

Latching (Bistable) Solenoid Valves

Conventional solenoid valves require continuous coil energization to maintain the actuated position, consuming power and generating heat throughout operation. Latching solenoid valves overcome this limitation through mechanical or magnetic latching mechanisms that maintain position without continuous power consumption.

**Mechanical latching valves** employ spring-loaded detents or over-center mechanisms that lock the valve in position once actuated. A brief pulse of electrical energy triggers actuation, but no further power is required until the valve must change state.

**Magnetic latching valves** use permanent magnets to hold the plunger in position after actuation. A momentary electrical pulse of one polarity actuates the valve to one position, while a pulse of opposite polarity returns it to the alternate state.

Latching valves dramatically reduce energy consumption, eliminate heat generation during steady-state operation, and maintain valve position during power failures. These advantages make them invaluable in battery-powered systems, energy-harvesting applications, remote installations with limited power, and safety-critical applications requiring predictable fail-position behavior.

The trade-off involves slightly more complex control circuitry to generate the bipolar pulses and potential position uncertainty if feedback isn’t provided. Additionally, latching mechanisms add mechanical complexity that may affect reliability in extremely high-cycle applications.

Material Selection and Construction Considerations

The construction materials for valve bodies, seals, and wetted components represent critical selection factors, particularly when handling aggressive chemicals, extreme temperatures, or demanding sanitary requirements.

Body Materials

**Brass:** The most economical option for general water and air service, brass offers good corrosion resistance and machinability. Suitable for most common industrial fluids at moderate temperatures and pressures.

**Stainless Steel:** Provides superior corrosion resistance for aggressive chemicals, high-purity applications, and elevated temperatures. Grade 316 stainless steel offers enhanced resistance to chlorides and acids compared to 304, making it preferred for marine environments and chemical processing.

**Plastic (PVC, PVDF, PTFE-lined):** Engineered plastics deliver excellent chemical resistance at lower cost and weight compared to stainless steel. PVDF (polyvinylidene fluoride) handles particularly aggressive acids and solvents. Plastic valves suit corrosive chemical service but have temperature and pressure limitations.

**Aluminum:** Lightweight and economical, aluminum works well for pneumatic applications and clean, dry air service but lacks corrosion resistance for many liquids.

Seal Materials

Seal material selection critically affects chemical compatibility, temperature range, and service life:

**NBR (Nitrile/Buna-N):** General-purpose seal material for petroleum oils, air, and water service. Good temperature range (-20°C to +90°C) and economical.

**EPDM (Ethylene Propylene):** Excellent for hot water, steam, and many acids and alkalis. Resists ozone and weathering. Temperature range: -40°C to +150°C.

**FKM (Viton/Fluorocarbon):** Superior chemical resistance and high-temperature capability (-20°C to +200°C). Handles most acids, solvents, and fuels. More expensive but essential for demanding chemical service.

**PTFE (Teflon):** Exceptional chemical inertness and temperature range (-200°C to +260°C). Suitable for virtually all chemicals but requires special valve designs to accommodate PTFE’s mechanical properties.

**Silicone:** Food-grade certifications and excellent temperature range (-60°C to +200°C). Used in sanitary applications and where odor/taste neutrality is critical.

Application-Specific Valve Types

Certain industries and applications have driven the development of specialized solenoid valve variants optimized for unique requirements.

Steam Service Valves

Steam applications impose severe demands—high temperature, pressure fluctuations, and potential water hammer. Steam-rated solenoid valves incorporate bronze or stainless steel bodies, high-temperature seals (typically PTFE or metal seals), and pilot-operated designs to handle the pressure forces involved. They often feature condensate drainage provisions and insulation to protect the solenoid from excessive heat.

Cryogenic Service Valves

Handling liquefied gases like nitrogen, oxygen, or LNG requires valves engineered for extreme cold. Extended solenoid bonnets thermally isolate the coil from cryogenic temperatures, while body materials are selected for low-temperature toughness. Special seals maintain flexibility at cryogenic temperatures without becoming brittle.

Sanitary and Hygienic Valves

Food, beverage, pharmaceutical, and biotechnology applications demand valves with smooth, crevice-free flow paths that resist bacterial growth and facilitate cleaning. Sanitary solenoid valves feature polished stainless steel bodies, diaphragm seals, and designs compliant with FDA, 3-A, and EHEDG standards. They accommodate clean-in-place (CIP) and steam-in-place (SIP) sterilization procedures.

Explosion-Proof and Intrinsically Safe Valves

Hazardous location applications require solenoid valves with appropriate certifications (ATEX, IECEx, Class I Division 1, etc.). Explosion-proof enclosures contain any spark or flame within the solenoid housing, while intrinsically safe designs limit electrical energy to levels incapable of igniting flammable atmospheres.

Selecting the Right Solenoid Valve

Choosing the optimal solenoid valve requires systematic evaluation of numerous application parameters:

**Fluid Characteristics:** Liquid, gas, or steam? Viscosity, cleanliness, and chemical composition drive material selection and valve style choices.

**Pressure and Temperature:** Operating and maximum values determine body rating, seal materials, and whether direct or pilot operation is appropriate.

**Flow Requirements:** Desired flow rate, acceptable pressure drop, and pipe size influence orifice sizing and valve configuration.

**Electrical Supply:** Available voltage (AC or DC), frequency, and power constraints guide coil selection.

**Response Time:** Critical applications may require the fastest possible actuation, favoring direct-acting designs.

**Duty Cycle:** Continuous vs. intermittent operation affects coil temperature rise and may suggest latching designs for energy conservation.

**Environmental Conditions:** Ambient temperature, humidity, vibration, and hazardous area classification impact housing and certification requirements.

**Control Strategy:** Simple on-off vs. proportional control, failsafe position requirements, and integration with control systems affect valve selection and accessories.

Conclusion: Matching Valve Technology to Application Needs

The diverse family of solenoid valve types reflects the breadth of industrial automation challenges these devices address. From simple two-way valves controlling water dispensers to sophisticated five-way valves orchestrating complex pneumatic sequences, solenoid technology provides reliable, precise, and cost-effective flow control across virtually every industrial sector.

Success in solenoid valve selection lies in understanding the fundamental operating principles, recognizing how different configurations address specific application requirements, and carefully matching valve capabilities to system demands. Whether prioritizing response speed, flow capacity, chemical compatibility, energy efficiency, or sanitary compliance, an appropriate solenoid valve type exists to meet the need.

As automation technology continues advancing and industries push into more demanding applications, solenoid valve designs will continue evolving. Enhanced materials, smarter control electronics, improved diagnostics, and innovative actuation mechanisms will expand the already impressive capabilities of these essential flow control devices. For engineers and technicians seeking to optimize system performance, comprehensive knowledge of solenoid valve types and their application remains an invaluable asset.