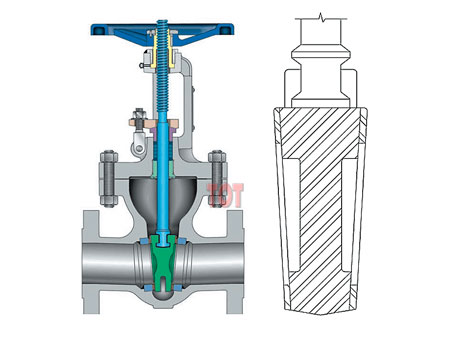

A wedge type gate valve is a common form of gate valve designed to regulate the flow of liquids or gases in pipelines by lifting or lowering a wedge-shaped gate. It is widely used in water supply, oil & gas, chemical, and power industries due to its reliable shut-off capabilities.

Table of Contents

Toggle🔧 What Is a Wedge Gate Valve?

A wedge gate valve operates by moving a solid or split wedge gate perpendicular to the flow of media. When the valve is closed, the wedge presses tightly against two seat rings to block flow. When opened, the gate lifts completely, allowing unobstructed flow.

Key characteristics:

Offers tight shutoff

Low pressure drop when fully open

Not suitable for throttling

🔍 Types of Wedge Gate Valves

There are three main types of wedge gate valves based on the wedge structure:

1. Solid Wedge Gate Valve

Most common type

One-piece solid wedge with a slight taper

Suitable for most fluids, including steam, gas, and oil

Simple and robust design

Limitation: can be prone to jamming in high-temperature fluctuations (thermal binding)

2. Flexible Wedge Gate Valve

One-piece wedge with a cut or groove to allow flexibility

Can adjust to minor seat misalignments and thermal expansion

Ideal for steam systems or systems with temperature variations

3. Split Wedge (Parallel Disk) Gate Valve

Two separate pieces held together with a spring or spacer

Each half seats independently for better alignment

Suitable for corrosive or high-temperature media

Less common but useful in demanding industrial applications

📌 Key Features of Wedge Type Gate Valves

Bidirectional flow – Can seal in both directions.

Full bore – No obstruction to the flow, minimizing pressure loss.

Metal-to-metal sealing – Reliable for high-pressure, high-temperature applications.

Rising or non-rising stem options – Depending on installation space and visibility needs.

🏭 Applications of Wedge Gate Valves

Widely used across many industries:

Water treatment plants – for isolating flow

Oil & gas pipelines – suitable for crude oil and gas systems

Power generation – especially in steam lines (use flexible wedge types)

Chemical plants – suitable for aggressive or high-pressure fluids

HVAC and plumbing systems

✅ Advantages

Strong sealing performance

Minimal pressure drop

Durable for high-pressure operations

Easy maintenance and parts replacement

⚠️ Limitations

Not recommended for throttling (can cause erosion and vibration)

Larger sizes may require significant force or motorized actuation

Thermal binding risk in solid wedge valves at high temperatures

🔩 Wedge Gate Valve vs Other Valves

| Feature | Wedge Gate Valve | Globe Valve | Ball Valve |

|---|---|---|---|

| Flow control | Poor (on/off only) | Excellent (throttling) | Limited |

| Pressure drop | Low | Medium to high | Very low |

| Sealing type | Metal-to-metal | Metal or soft seat | Usually soft seat |

| Maintenance | Moderate | Higher | Low |

📚 Conclusion

The wedge type gate valve remains a trusted choice for applications requiring tight shut-off, durability, and full-bore flow. Whether you’re specifying valves for an industrial pipeline or a municipal water system, understanding the **different wedge types—solid, flexible, or split—**will help ensure performance and longevity.