A proportional valve adjusts its valve opening continuously based on an input signal (usually a voltage or current, such as 0–10 V or 4–20 mA).

The higher the input signal, the more the valve opens; the lower the signal, the more it closes.

In simple terms:

Electrical signal → proportional valve movement → controlled flow or pressure

This makes proportional valves ideal for applications that require smooth, accurate, and variable control.

Table of Contents

ToggleHow Does a Proportional Valve Work?

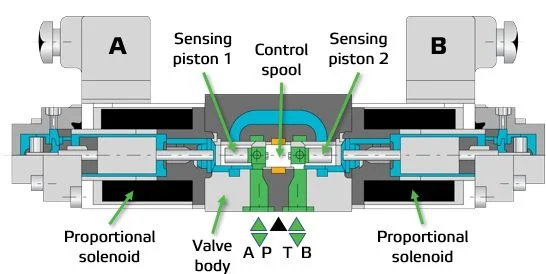

A proportional valve typically consists of:

Solenoid or proportional actuator

Valve spool or poppet

Electronic driver (amplifier)

Working principle:

A controller sends an electrical signal

The proportional solenoid converts the signal into magnetic force

The valve spool moves partially, not just on/off

Fluid flow or pressure changes proportionally

Unlike standard solenoid valves, the spool position is continuously adjustable.

Proportional Valve vs On/Off Valve

| Feature | Proportional Valve | On/Off Valve |

|---|---|---|

| Control type | Variable / continuous | Binary (open or closed) |

| Precision | High | Low |

| Motion | Smooth | Sudden |

| Energy efficiency | Better in many systems | Lower |

| Typical signal | Analog (0–10V, 4–20mA) | Digital (0 or 1) |

Types of Proportional Valves

1. Proportional Flow Control Valve

Regulates flow rate

Used to control speed of actuators

2. Proportional Pressure Control Valve

Controls system pressure

Includes pressure-reducing and relief variants

3. Proportional Directional Control Valve

Controls direction and speed

Common in hydraulic machinery

Applications of Proportional Valves

Proportional valves are widely used in industries that require precise motion and force control, such as:

Hydraulic machinery

Injection molding machines

Construction equipment

Industrial automation

Wind power systems

Robotics

Marine and offshore equipment

Advantages of Proportional Valves

Precise control of flow and pressure

Smooth system operation

Reduced mechanical shock

Improved energy efficiency

Easy integration with PLCs and controllers

Limitations to Consider

More expensive than on/off valves

Sensitive to fluid contamination

Requires proper electronic control and tuning

Proportional Valve vs Servo Valve

| Aspect | Proportional Valve | Servo Valve |

|---|---|---|

| Accuracy | High | Very high |

| Cost | Moderate | Expensive |

| Contamination tolerance | Better | Poor |

| Complexity | Lower | Higher |

Proportional valves are often chosen as a cost-effective alternative to servo valves.

Conclusion

A proportional valve is a key component in modern hydraulic and pneumatic systems, enabling precise, smooth, and efficient control of fluid flow or pressure based on electrical signals.

If your application needs variable control instead of simple on/off operation, a proportional valve is usually the right choice.