Valve trim refers to all the internal components of a valve that come into direct contact with the flowing fluid and control the movement, direction, or shutoff of that flow. Trim determines how a valve performs—its sealing ability, durability, resistance to corrosion/erosion, and overall service life.

Because valve trim directly affects performance, it is one of the most important considerations when selecting industrial valves.

Table of Contents

ToggleWhat Is Included in Valve Trim? (Full Definition)

While different valve standards define trim slightly differently, valve trim generally includes:

Disc / Plug / Ball / Gate (primary closure element)

Seat (or seat rings)

Stem

Backseat

Cage (in control valves)

Guides and bushings

Retainers or discs in multi-stage trims

In simple terms: Trim = all moving, sealing, or wear-prone parts of a valve.

These components experience pressure, temperature extremes, corrosion, erosion, and mechanical wear—so trim material selection is critical.

Why Valve Trim Matters

Choosing the correct trim determines:

✔ Shutoff performance

A poor trim-seat combination leads to internal leakage.

✔ Flow control accuracy

Control valves depend heavily on trim geometry.

✔ Resistance to corrosion & erosion

Wrong trim = rapid failure, especially in abrasive or corrosive fluids.

✔ Safety

Incorrect trim may fail under high pressure or temperature.

✔ Service life & maintenance cost

Trim is usually the first part to wear out.

Common Valve Trim Components Explained

1. Disc / Gate / Plug / Ball

The main closure element that blocks or regulates flow.

2. Seat (Seat Ring)

The sealing surface that the disc or plug contacts to stop flow.

3. Stem

Transfers actuator or handwheel motion to the closure element.

4. Backseat

Provides a secondary seal when the valve is fully open.

5. Cage (Control Valves)

Controls flow pattern, reduces noise, keeps plug aligned.

6. Guides & Bushings

Ensure smooth movement and reduce vibration.

Valve Trim Types (Functional)

Valve trim can be categorized based on the valve’s function:

• On/Off Trim

Used in gate, ball, and plug valves for tight shutoff.

• Throttling Trim

Used in globe and control valves; includes:

Linear trim

Equal percentage trim

Quick-opening trim

Multi-stage anti-cavitation trim

• Balanced Trim

Reduces force needed for operation (e.g., double-seated globe valves).

Valve Trim Materials (API Trim Numbers Overview)

Valve manufacturers often refer to trim using API trim numbers (from API 600, 602, 603).

Common examples:

| Trim Number | Material | Usage |

|---|---|---|

| Trim 1 | 410 SS | General service |

| Trim 5 | HF (hard-faced) Stellite seat & disc | High temperature, abrasion |

| Trim 8 | 304 SS | Corrosion-resistant |

| Trim 12 | 316 SS | More corrosion-resistant |

| Trim 13 | Monel | Chlorides, seawater |

| Trim 20 | Alloy 20 | Sulfuric acid |

| Trim 21 | Hastelloy | Highly corrosive environments |

If fluid is corrosive, erosive, acidic, or high-temperature: the trim material must be selected carefully.

How to Choose the Right Valve Trim

When selecting trim, consider:

1. Fluid Type

Corrosive fluids → stainless steel, Monel, Hastelloy

Abrasive fluids → hard-faced trims (Stellite)

2. Pressure & Temperature

High pressure → hardened trim

High temperature → Stellite, hard-faced seats

3. Valve Function

Control valves need characterized trim (linear, equal %).

On/off valves need durable seat materials.

4. Leakage Class

Class IV, V, VI for control valves

Metal vs soft seats

5. Expected lifespan & maintenance

Harder materials = longer service but higher cost.

Examples of Valve Trim in Different Valve Types

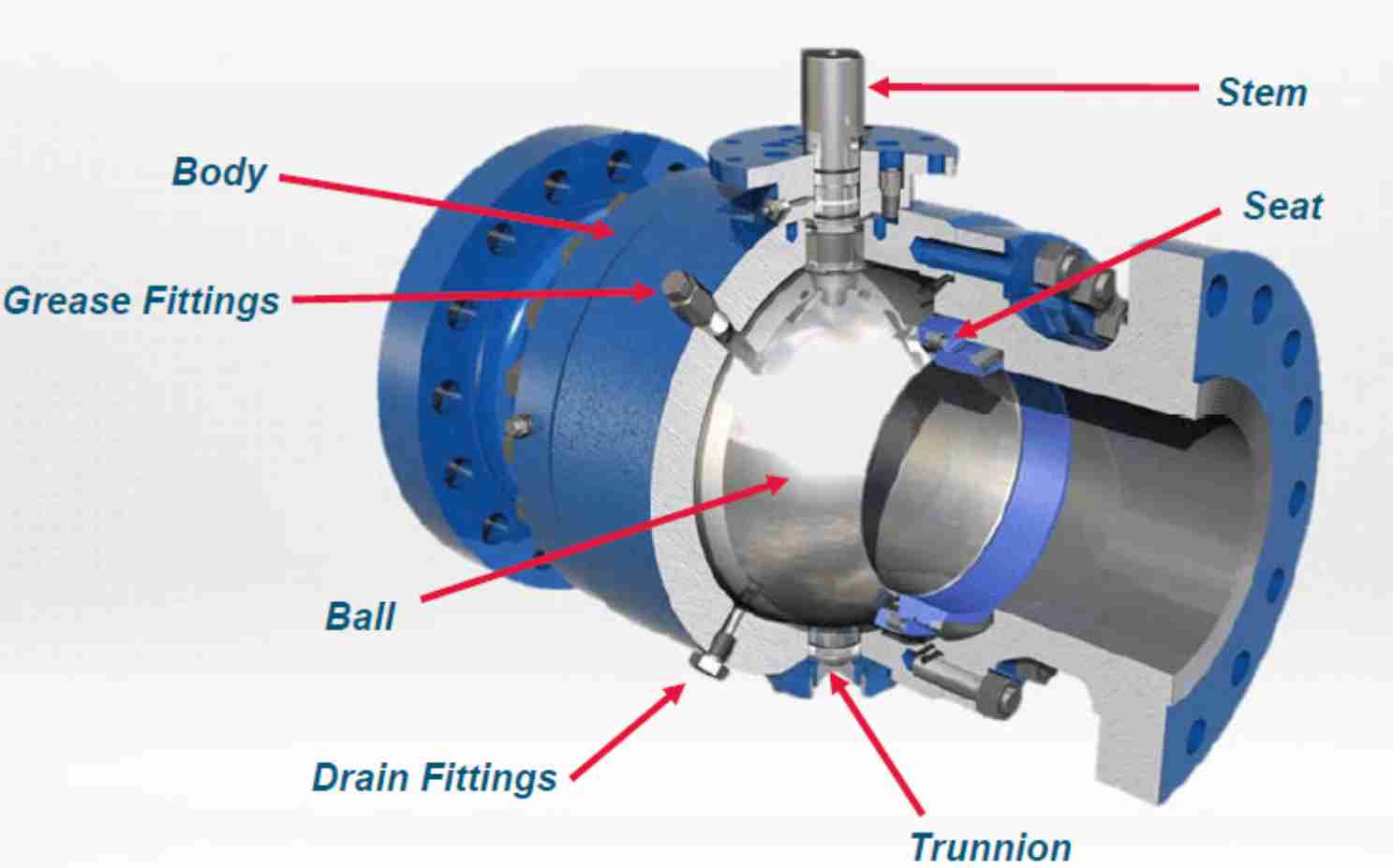

Ball Valve Trim

Ball

Seats (PTFE, RPTFE, metal)

Stem

Body seals

Gate Valve Trim

Gate/disc

Seat rings

Stem

Backseat

Globe Valve Trim

Plug

Seat ring

Stem

Cage

Guides

Butterfly Valve Trim

Disc

Seat (elastomer or metal)

Stem

Valve Trim vs. Valve Body Material

| Component | Purpose |

|---|---|

| Body material | Handles pressure containment |

| Trim material | Handles fluid exposure and sealing |

They are selected independently.

For example, a carbon-steel valve body may have 316 stainless steel trim for corrosion resistance.

Valve Trim FAQ

What is the function of valve trim?

To regulate, shut off, or throttle flow and provide sealing.

What is the difference between trim and valve body?

Trim contacts the fluid; the body only contains pressure.

Is trim the same for all valve types?

No—ball, gate, globe, and control valves use different trim designs.

Why do valves have trim numbers (e.g., API Trim 8)?

Trim numbers identify material combinations for consistent specification.

Conclusion

Valve trim includes all internal, fluid-contacting components that control or shut off flow. It is the heart of the valve, determining performance, sealing capability, corrosion resistance, and service life.

Choosing the correct trim is essential to ensuring:

Proper operation

Long-term durability

Safety

Low maintenance costs