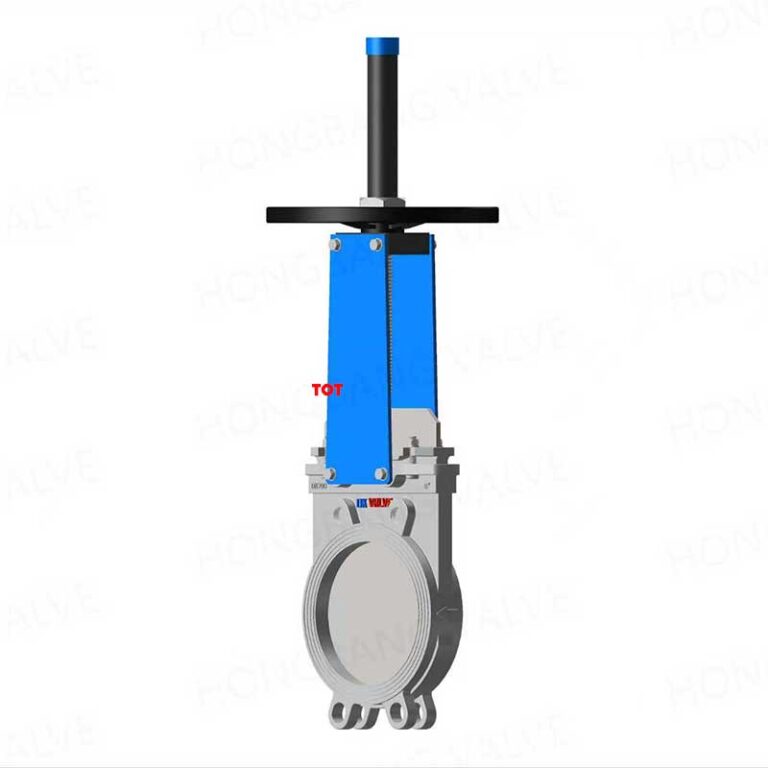

DN100 Knife Gate Valve (4 Inch)

The DN100 knife gate valve represents the perfect balance of performance, reliability, and versatility for critical 4-inch pipeline systems. Engineered as the industry standard for medium-bore applications, this valve excels in mining operations, water treatment facilities, pulp & paper mills, and chemical processing plants where reliable isolation and superior cutting performance are essential for operational success.

Key Applications: Mining & Metallurgy • Water Treatment • Pulp & Paper • Chemical Processing • Power Generation • Oil & Gas • Steel Industry • Cement Manufacturing

Why Choose DN100 Knife Gate Valve?

✓ Industry Standard Performance

- Proven 4-inch design optimized for medium-bore industrial applications

- Enhanced flow capacity (Cv 360) for maximum system efficiency

- Superior pressure handling capability up to 25 Bar

✓ Unmatched Reliability

- Field-proven performance in the harshest industrial environments

- Extended service life with reinforced components and advanced materials

- Zero-maintenance design reduces total cost of ownership

✓ Versatile Application Range

- Excellent performance in both clean and heavily contaminated media

- Handles fibrous materials, abrasive slurries, and corrosive chemicals

- Suitable for continuous operation and frequent cycling

✓ Premium Construction Options

- Wafer Type: 51mm face-to-face, cost-effective installation

- Lug Type: Independent mounting with superior maintenance access

- Flanged Type: 75mm face-to-face, maximum structural integrity and pressure capability

Technical Specifications

| Parameter | Specification |

|---|---|

| Nominal Size | DN100 (4 inches) |

| Pressure Rating | PN6/10/16/25/40, ANSI 150/300/600/900 |

| Working Pressure | Up to 40 Bar (580 PSI) |

| Temperature Range | -29°C to +500°C |

| Cv Value | 360 (full open) |

| Body Materials | WCB, WC6, WC9, CF8, CF8M, CF3M, Duplex 2205, Super Duplex 2507, Alloy 20, Hastelloy C276 |

| Standards | MSS SP-81, API 6D, ASME B16.5, EN 1092, AWWA C515, ISO 14313 |

| End Connections | RF, FF, RTJ, Groove, Weld End, NPT Threaded |

Configuration Options & Dimensions

Wafer Type DN100

- Face-to-Face: 51mm

- Weight: 25-32 kg

- Best For: Retrofit applications, space-constrained installations

Lug Type DN100

- Face-to-Face: 51mm

- Weight: 30-38 kg

- Best For: Dead-end service, easy maintenance, modular systems

Flanged Type DN100

- Face-to-Face: 75mm

- Weight: 35-48 kg

- Best For: High pressure, critical applications, permanent installations

Performance Data

| Performance Parameter | Value |

|---|---|

| Maximum Flow Rate (Water) | 600 m³/h |

| Maximum Flow Rate (Slurry) | 480 m³/h |

| Pressure Drop (Full Open) | 0.05 Bar |

| Operating Torque | 60-120 Nm |

| Closing Time (Manual) | 25-35 seconds |

| Cycle Life | 25,000+ cycles |

| Leakage Rate | Zero (Class VI) |

| Noise Level | <60 dB(A) |

| Response Time (Actuated) | 15-60 seconds |

Critical Industrial Applications

Mining & Metallurgical Processing

- Concentrate and tailings transport

- Flotation circuit isolation and control

- Thickener underflow and overflow systems

- Process water and reclaim circuits

- Acid mine drainage treatment

Municipal & Industrial Water Treatment

- Primary and secondary clarification

- Activated sludge and biological treatment

- Chemical feed and polymer systems

- Backwash and cleaning circuits

- Effluent discharge and reuse systems

Pulp & Paper Manufacturing

- Stock preparation and screening

- Bleaching and brightening systems

- Paper machine water systems

- Waste treatment and recovery

- Chemical recovery processes

Chemical & Petrochemical Industries

- Reactor isolation and emergency shutdown

- Catalyst handling and regeneration

- Slurry and viscous media transfer

- Waste treatment and neutralization

- Process cooling and heating circuits

Power Generation

- Coal and ash handling systems

- Flue gas desulfurization (FGD)

- Cooling tower and condenser systems

- Boiler feedwater treatment

- Waste heat recovery systems

Advanced Actuation & Control

Manual Operation Systems

- Heavy-Duty Handwheel: Ergonomic design with mechanical advantage

- Precision Gear Drive: 4:1 to 6:1 reduction for high-pressure applications

- Chainwheel Operation: Up to 6 meters chain length for elevated installations

- Extended Stem Designs: Custom lengths for buried service applications

Pneumatic Actuation Systems

- Fail-Safe Spring Return: Emergency positioning for critical applications

- Double Acting Control: Precise positioning with variable air supply

- High-Output Torque: Up to 3000 Nm for demanding applications

- Smart Pneumatic Positioners: Digital control with diagnostic capabilities

Electric Actuation Systems

- Multi-Turn Electric Motors: Variable speed with precise torque control

- Explosion-Proof Certification: ATEX/IECEx/CSA approved for hazardous areas

- Advanced Position Control: Servo-quality positioning with feedback

- Network Integration: Profibus, Foundation Fieldbus, HART, Modbus compatibility

Hydraulic Actuation (Special Applications)

- High-Force Output: Up to 5000 Nm for extreme service conditions

- Fail-Safe Accumulator Systems: Emergency operation capability

- Proportional Control: Precise throttling and positioning

- Subsea and Offshore Rated: Special sealing and materials

Advanced Materials Engineering

Body Materials Portfolio

- WCB: Carbon steel for standard industrial service

- WC6 (1.25Cr-0.5Mo): Enhanced temperature and hydrogen service

- WC9 (2.25Cr-1Mo): High temperature and pressure applications

- CF8 (304 SS): General corrosion resistance

- CF8M (316 SS): Superior chemical compatibility

- CF3M (316L SS): Low carbon for welding and severe corrosion

- Duplex 2205: High strength with excellent corrosion resistance

- Super Duplex 2507: Extreme corrosion resistance for offshore/marine

- Alloy 20: Exceptional chemical resistance

- Hastelloy C276: Ultimate corrosion resistance for severe chemical service

Advanced Gate Technology

- Standard Stainless: 304/316/316L with precision machined surfaces

- Through-Hardened: Heat treated for maximum wear resistance

- Stellite 6 Overlay: Cobalt-based hardfacing for extreme abrasion

- Tungsten Carbide Coating: Advanced coating for ultimate wear resistance

- Ceramic Coating: Alumina or zirconia for chemical resistance

Engineered Seat Systems

- High-Performance Elastomers:

- EPDM: General service (-20°C to +120°C)

- NBR: Petroleum products (-40°C to +100°C)

- FKM (Viton): Chemical resistance (-26°C to +200°C)

- FFKM (Kalrez): Ultimate chemical resistance (-15°C to +250°C)

- HNBR: Enhanced oil and chemical resistance

- Metal Seat Technology:

- Stellite 6: Standard metal seating

- Stellite 21: Enhanced corrosion resistance

- Inconel 625: High temperature applications

- Custom alloys for specific applications

Quality Excellence & Compliance

Manufacturing Standards

- ISO 9001:2015 – Quality Management System

- ISO 14001:2015 – Environmental Management

- API Q1 9th Edition – Quality management for petroleum industry

- PED 2014/68/EU – Pressure Equipment Directive

- ASME Section VIII – Pressure vessel code compliance

Testing & Validation Protocols

- Pressure Testing: Shell test at 1.5× working pressure, seat test at 1.1× working pressure

- Advanced Leakage Testing: Helium mass spectrometer testing available

- Torque Validation: Operating, seating, and break torque verification

- Extended Cycle Testing: 50,000+ cycle endurance validation

- Material Verification: PMI, mechanical properties, corrosion testing

Global Certifications

🔥 API 607/6FA – Fire testing and emergency sealing

⚡ ATEX 2014/34/EU – European explosive atmosphere directive

🇺🇸 CSA/UL – North American electrical and safety standards

🌊 NSF/ANSI 61 – Drinking water system components

🏭 NACE MR0175/ISO 15156 – Sour service environments

📋 ISO 15848-1 – Fugitive emissions testing

🍎 FDA 21 CFR 177 – Food contact applications

⚓ DNV GL – Marine and offshore applications

Installation & Service Excellence

Installation Requirements

- Pipeline Configuration: 8D upstream, 4D downstream straight pipe recommended

- Support Requirements: Independent structural support for flanged configurations

- Orientation Capability: 360° installation orientation capability

- Access Requirements: 500mm minimum clearance for maintenance access

Predictive Maintenance Program

- Condition Monitoring: Vibration, temperature, and torque trending

- Smart Diagnostics: Actuator health monitoring and fault prediction

- Scheduled Inspections: Customized maintenance intervals based on service conditions

- Component Life Tracking: Predictive replacement scheduling

Global Service Network

- Service Centers: 65+ authorized centers across 6 continents

- Emergency Response: 24/7/365 technical support and rapid deployment

- Field Service Teams: Factory-trained technicians for on-site service

- Training Academy: Comprehensive programs for operators and maintenance personnel

Digital Service Platform

- Remote Monitoring: IoT-enabled condition monitoring

- Digital Twin Technology: Virtual valve modeling for optimization

- Augmented Reality: AR-assisted maintenance and troubleshooting

- Blockchain Documentation: Immutable service and certification records

Technical Dimensions & Standards

Standard Dimensions (Multiple Pressure Classes)

| Type | PN16 | PN25 | ANSI 150 | ANSI 300 | Weight Range (kg) |

|---|---|---|---|---|---|

| Wafer | 51mm | 51mm | 51mm | 51mm | 28-35 |

| Lug | 51mm | 51mm | 51mm | 51mm | 33-42 |

| Flanged | 75mm | 78mm | 76mm | 89mm | 38-55 |

International Flange Standards Compatibility

| Standard | Bolt Circle | Holes | Bolt Size | Flange OD | RF Height |

|---|---|---|---|---|---|

| ANSI B16.5 150# | 157.2 mm | 8 × M16 | 5/8″ | 228.6 mm | 2.0 mm |

| ANSI B16.5 300# | 157.2 mm | 8 × M20 | 5/8″ | 254.0 mm | 2.0 mm |

| EN 1092-1 PN16 | 160 mm | 8 × M16 | M16 | 235 mm | 2.0 mm |

| EN 1092-1 PN25 | 160 mm | 8 × M16 | M16 | 235 mm | 2.0 mm |

| JIS B2220 10K | 160 mm | 8 × M16 | M16 | 220 mm | 1.5 mm |

| AS 2129 Table D | 160 mm | 8 × M16 | M16 | 235 mm | 2.0 mm |

Performance Validation & Case Studies

Independent Testing Results

- Cycle Life Testing: >50,000 cycles in mining tailings service

- Seat Integrity: Zero leakage maintained after 25,000 cycles

- Torque Stability: <3% variation over 10,000 cycle test

- Corrosion Testing: 316L SS validated for >25 years in seawater service

Real-World Performance Data

- Copper Mine (Chile): 8 years continuous operation, zero unscheduled maintenance

- Paper Mill (Finland): 50,000+ cycles/year, original components still in service

- Wastewater Plant (USA): 15+ years operation with only scheduled maintenance

- Chemical Plant (Germany): Severe chemical service with custom Hastelloy construction

Third-Party Validation

- University Research: Independent flow and cavitation studies

- Industry Testing Labs: Accelerated life testing and failure analysis

- Customer Validation: Long-term field testing programs

- Regulatory Approval: Multiple international agency certifications

Competitive Excellence

🏆 Industry Leadership – #1 choice for medium-bore industrial applications

⚡ Superior Performance – Highest Cv rating in class for maximum flow efficiency

🛡️ Proven Reliability – Extensive field validation across all major industries

🔬 Advanced Materials – Widest selection of specialty alloys and coatings

🌍 Global Support – Comprehensive service network with local expertise

📦 Rapid Delivery – Standard and custom configurations with industry-leading lead times

💡 Innovation Leader – Continuous R&D investment in next-generation valve technology

🎓 Technical Expertise – Application engineering support for complex requirements

Get Your DN100 Industrial Solution

Ready to optimize your critical 4-inch industrial systems? Our DN100 specialists provide comprehensive application engineering and support for your most demanding process requirements.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.