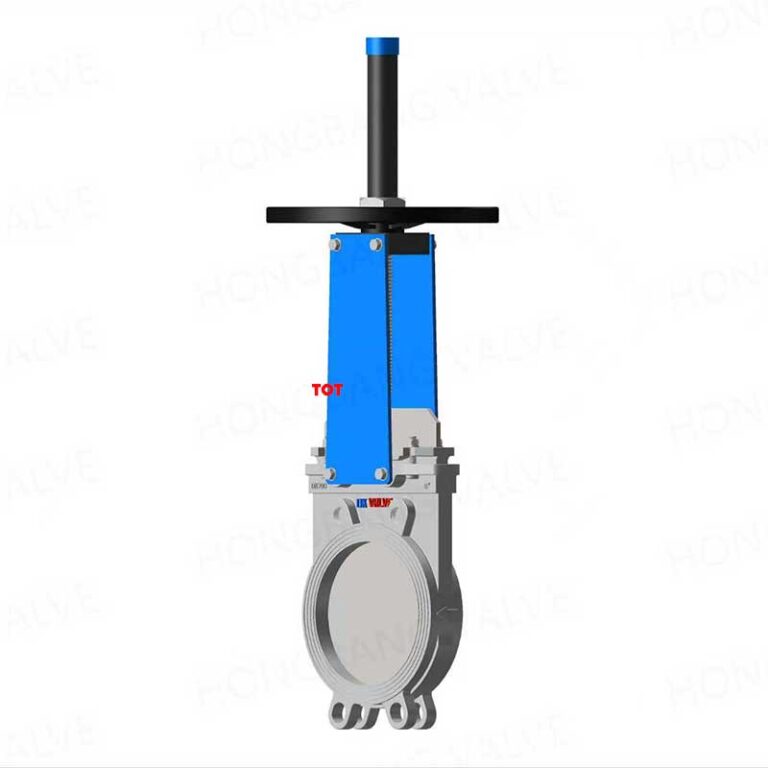

DN125 Knife Gate Valve (5 Inch)

The DN125 Knife Gate Valve is a professional industrial valve designed with a sharp-edged gate that effectively cuts through fibrous, granular, or viscous media. This valve offers excellent shut-off performance and sealing capabilities, making it ideal for demanding applications in pulp & paper, wastewater treatment, mining, and other process industries.

Technical Specifications

Basic Parameters

- Nominal Diameter: DN125 (5 inches)

- Connection Type: Flanged, Wafer, Welded

- Structure: Rising stem, Non-rising stem

- Actuation: Manual, Pneumatic, Electric, Hydraulic

- Flow Direction: Bidirectional sealing

Pressure Ratings

- Nominal Pressure: PN6, PN10, PN16, PN25

- Working Pressure: 0.6-2.5 MPa (87-363 PSI)

- Test Pressure: Per GB/T 13927, API 598 standards

Temperature Range

- Operating Temperature: -20°C to +200°C (-4°F to +392°F)

- Media Temperature: Depending on seal material selection

Key Features

Structural Advantages

- Knife-Edge Gate: Sharp cutting edge effectively shears fibrous and sticky media

- Full Port Design: Unrestricted flow path when fully open, minimal pressure drop

- Bidirectional Sealing: Reliable sealing from both upstream and downstream

- Compact Design: Short face-to-face dimension, space-saving installation

Performance Benefits

- Superior Cutting Capability: Handles fibrous and particulate media effectively

- Excellent Sealing: Resilient seat design ensures reliable shut-off

- Easy Operation: Low operating torque for effortless operation

- Low Maintenance: Simple design reduces maintenance costs

Material Options

Body Materials

- Cast Iron: HT200, HT250

- Carbon Steel: WCB, A216 WCB

- Stainless Steel: CF8 (304), CF8M (316), CF3 (304L), CF3M (316L)

- Alloy Steel: WC6, WC9

Gate Materials

- Stainless Steel: 304, 316, 316L, 17-4PH

- Alloy Steel: Selected based on media requirements

- Surface Treatment: Hardening, coating options available

Seal Materials

- Nitrile Rubber (NBR): Oil and water applications

- EPDM: Steam and hot water service

- Viton (FKM): Chemical resistance applications

- PTFE: Highly corrosive media

Applications

Primary Industries

- Pulp & Paper: Pulp stock, white water systems

- Wastewater Treatment: Sludge handling, effluent systems

- Mining: Slurry transport, tailings processing

- Food Processing: Fruit pulp, syrup, viscous products

- Chemical Processing: Chemical slurries, catalyst handling

Typical Service Conditions

- Fibrous media pipeline systems

- Solid-laden slurry transport

- Viscous media shut-off control

- Corrosive media sealing requirements

Installation & Maintenance

Installation Requirements

- Verify valve specifications match design requirements

- Ensure pipeline flanges are flat and bolt specifications are correct

- Install valve in closed position

- Provide adequate clearance for operation and maintenance

Maintenance Guidelines

- Regularly inspect sealing surfaces and gate wear

- Maintain proper lubrication of operating mechanisms

- Periodically test valve opening and closing performance

- Replace worn components as needed

Design Standards

Compliance Standards

- Design: API 6A, ASME B16.34

- Testing: API 598, ISO 5208

- Face-to-Face: ASME B16.10, EN 558

- Flanges: ASME B16.5, EN 1092

Quality Certifications

- ISO 9001:2015 Quality Management

- CE Marking (where applicable)

- API 6A Certification

- Material Certificates per EN 10204 3.1

Ordering Information

Model Code

DN125-KGV-[Pressure Rating]-[Material]-[Actuation]-[Connection]

Information Required for Ordering

- Nominal diameter and pressure rating

- Service media and temperature range

- Body and trim material requirements

- Actuation type and connection style

- Special technical requirements

Available Options

- Actuators: Manual handwheel, pneumatic, electric, hydraulic

- Connections: RF flanged, RTJ flanged, wafer, lug style

- Coatings: Epoxy, polyurethane, specialized coatings

- Testing: Standard factory test, witnessed testing, special certifications

Quality Assurance

- Factory testing per ISO 5208 and API 598 standards

- Material certificates and test documentation provided

- Comprehensive warranty coverage

- Global technical support and service network

- Spare parts availability guarantee

Technical Support

Our experienced engineering team provides:

- Application consultation and valve selection

- Custom design solutions for special requirements

- Installation and commissioning support

- Training programs for maintenance personnel

- 24/7 technical support hotline

Note: This product can be customized according to specific customer requirements. Final technical parameters are subject to confirmed drawings and technical agreements.

For additional technical information, quotations, or application support, please contact our technical sales team.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.