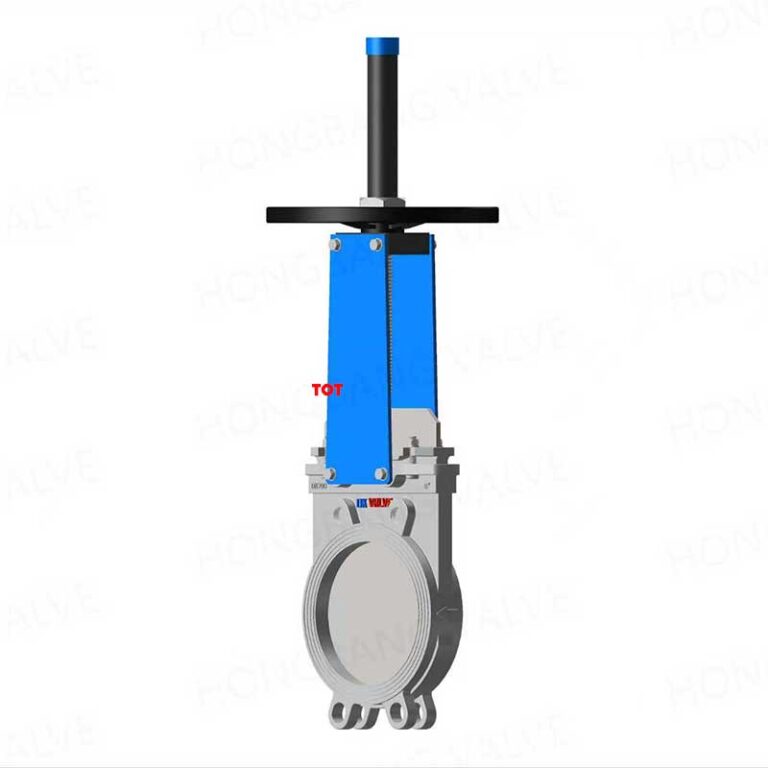

DN300 Knife Gate Valve (12 Inch)

The DN300 Knife Gate Valve represents the pinnacle of industrial valve engineering for 12-inch heavy-duty applications, embodying four decades of innovation in severe service valve technology. This flagship valve system is engineered to dominate the most extreme operating conditions in large-scale industrial installations, where conventional valves fail. Designed for continuous operation in major industrial complexes, mega-scale pulp mills, metropolitan treatment facilities, and heavy processing industries, the DN300 delivers uncompromising performance, absolute reliability, and operational excellence under the harshest service conditions imaginable.

Technical Specifications

Performance Parameters

- Nominal Diameter: DN300 (12 inches)

- Full Port Flow Area: 300mm (11.81″) completely unobstructed passage

- Connection Standards: ANSI/ASME B16.5/B16.47 Series A&B, DIN/EN 1092-1/2, API 6A Type 6BX/6B

- Advanced Configurations: Rising stem, Non-rising stem, Enclosed bonnet, Bellows seal, Double block & bleed

- Actuation Technologies: Manual, Pneumatic, Electric, Electrohydraulic, Smart integrated systems, Hybrid actuation

- Multi-Directional Service: Bidirectional sealing with pressure-assisted seat energization

Ultimate Pressure Capabilities

- ANSI Pressure Classes: 150, 300, 600, 900, 1500, 2500, Special Class 4500

- DIN/EN Pressure Ratings: PN6, PN10, PN16, PN25, PN40, PN63, PN100, PN160, PN250

- Working Pressure Spectrum: 0.6-40.0 MPa (87-5800 PSI)

- Maximum Design Pressure: Up to 69.0 MPa (10,000 PSI) with ultra-high pressure design

- Hydrostatic Test Standards: API 598, ISO 5208, EN 12266 with 1.5-2.0 safety factors

- Pressure Shock Resistance: Rapid pressure cycling and water hammer protection

Extreme Temperature Performance

- Standard Operating Range: -73°C to +400°C (-100°F to +750°F)

- Cryogenic Service Capability: -269°C (-452°F) for liquid helium applications

- Ultra-High Temperature Service: Up to 1000°C (1832°F) for specialized metallurgy

- Thermal Shock Resistance: 200°C/minute temperature ramp capability

- Multi-Zone Temperature Control: Independent heating/cooling zones available

- Insulation Integration: Custom thermal management systems

Mechanical & Dimensional Specifications

- Face-to-Face Dimensions: ASME B16.10, EN 558-1, API 6D, AWWA C500, Custom lengths

- Overall Assembly Height: 1000-2200mm (application and actuation dependent)

- Flange Drilling Compatibility: Global standards including ASME, EN, API, JIS, GOST

- Operating Weight Range: 200-600 kg (depending on materials, pressure rating, and actuator)

- Maximum Operating Torque: 5,000-25,000 Nm (varies by configuration and pressure)

- Seismic Qualification: IEEE 344, UBC Zone 4, custom seismic analysis available

Revolutionary Engineering Technologies

Next-Generation Cutting Systems

- Molecular-Sharp Knife Edge: Precision CNC-machined with 20° optimized cutting geometry

- Self-Maintaining Sharpness: Advanced metallurgy maintains cutting efficiency throughout service life

- Multi-Stage Cutting Action: Progressive cutting zones for different media types

- Debris Management System: Integrated debris collection and ejection mechanisms

- Cavitation-Immune Design: Anti-cavitation trim prevents erosion and extends service life

- Bi-Directional Cutting: Equal cutting performance in both flow directions

Advanced Sealing Technologies

- Quad-Sealing Architecture: Primary, secondary, tertiary, and emergency seal systems

- Pressure-Adaptive Sealing: Upstream pressure enhances sealing force automatically

- Zero-Emission Guarantee: Fugitive emission compliance exceeding ISO 15848 Class AH

- Self-Compensating Seats: Automatic wear compensation maintains seal integrity

- Emergency Injectable Sealing: Field-injectable compounds for emergency seal restoration

- Cryogenic Seal Technology: Specialized low-temperature sealing solutions

Intelligent Valve Systems

- AI-Powered Diagnostics: Machine learning algorithms for predictive maintenance

- Digital Twin Integration: Real-time virtual model synchronization

- Edge Computing Capability: Local processing for immediate decision-making

- Blockchain Security: Immutable operational records and cyber-attack protection

- 5G Connectivity: Ultra-low latency communication for critical control applications

- Autonomous Operation: Self-optimizing performance based on operating conditions

Extreme Service Engineering

- Multi-Phase Flow Handling: Gas-liquid-solid mixtures up to 70% solids content

- Erosion-Resistant Design: Advanced fluid dynamics minimize internal wear

- Corrosion Immunity Systems: Multiple barrier protection against chemical attack

- Vibration Isolation: Advanced dampening systems prevent resonance damage

- Electromagnetic Compatibility: EMI/RFI shielding for electronic components

- Radiation Hardened Options: Nuclear service capable components and materials

Ultra-Premium Material Portfolio

Advanced Structural Materials

- Super-Austenitic Stainless Steels:

- 254 SMO (UNS S31254): Superior seawater and chloride resistance

- AL-6XN (UNS N08367): Exceptional corrosion resistance and strength

- 654 SMO (UNS S32654): Ultra-high molybdenum content for extreme environments

- Custom super-austenitics for specific chemical compatibility

- Duplex & Super Duplex Alloys:

- SAF 2205 (UNS S31803): Standard duplex for moderate corrosive service

- SAF 2507 (UNS S32750): Super duplex for severe corrosive environments

- Zeron 100 (UNS S32760): Ultra-high performance super duplex

- SAF 2906 (UNS S29060): Premium super duplex for critical applications

- Nickel-Based Superalloys:

- Hastelloy C-276: Universal corrosion resistance champion

- Inconel 625: High-temperature strength with corrosion resistance

- Inconel 686: Enhanced molybdenum content for severe chemical service

- Hastelloy C-22: Exceptional performance in oxidizing and reducing environments

- Custom nickel alloys for specialized applications

- Exotic & Specialty Materials:

- Titanium Grade 2/7/12: Lightweight with exceptional corrosion resistance

- Zirconium 702/705: Nuclear and severe chemical applications

- Tantalum: Ultimate chemical inertness for pharmaceutical applications

- Niobium: Superconducting and ultra-pure applications

- Tungsten alloys: Extreme temperature and wear resistance

Next-Generation Sealing Materials

- Ultra-High Performance Elastomers:

- FFKM (Perfluoroelastomer): -25°C to +327°C, universal chemical resistance

- FEPM (Tetrafluoroethylene propylene): -10°C to +230°C, steam resistance

- Custom compound elastomers for specific chemical compatibility

- Plasma-resistant compounds for semiconductor applications

- FDA/USP Class VI compounds for food and pharmaceutical service

- Advanced Thermoplastic Sealing:

- PEEK (Polyetheretherketone): High-temperature, chemical-resistant

- PPS (Polyphenylene sulfide): Chemical resistance and dimensional stability

- PTFE compounds: Enhanced wear resistance and lower permeation

- Custom fluoropolymer compounds for specialized applications

Comprehensive Industrial Applications

Mega-Scale Pulp & Paper Operations

- Advanced Fiber Processing:

- Ultra-high consistency pulp systems (15% consistency capable)

- Advanced brownstock washing with counter-current flows

- Multi-stage oxygen delignification systems

- Ozone and hydrogen peroxide bleaching sequences

- Advanced screening and cleaning with high rejection rates

- Integrated Chemical Recovery:

- Black liquor multiple-effect evaporators

- Recovery boiler systems and ash handling

- Causticizing and lime kiln operations

- Green liquor dregs and lime mud processing

- Methanol and turpentine recovery systems

- Next-Generation Paper Machines:

- Multi-layer headbox dilution water systems

- Advanced dewatering and press section applications

- Coating kitchen and curtain coater operations

- Calender stack hydraulic systems

- Waste heat recovery and steam systems

Metropolitan Water Infrastructure

- Primary Treatment Systems:

- Large-capacity raw water intake structures

- High-rate clarification and sedimentation systems

- Advanced screening and grit removal operations

- Primary sludge thickening and pumping systems

- Chemical feed systems for coagulation and pH control

- Advanced Secondary Treatment:

- Large-scale activated sludge process control

- Biological nutrient removal (BNR) systems

- Membrane bioreactor (MBR) concentrate handling

- Secondary clarifier sludge and scum systems

- Advanced oxidation process (AOP) applications

- Biosolids Processing Systems:

- Anaerobic digestion feed and withdrawal systems

- Mesophilic and thermophilic digester operations

- Biogas collection and upgrading systems

- Advanced dewatering with polymer conditioning

- Thermal hydrolysis and advanced treatment processes

Heavy Mining & Metallurgical Processing

- Large-Scale Mineral Processing:

- Primary and secondary grinding circuit control

- High-density thickener underflow systems

- Large-capacity flotation cell applications

- Concentrate and tailings pipeline systems

- Hydrometallurgical leaching and precipitation

- Advanced Coal Processing:

- Heavy media separation dense medium systems

- Fine coal flotation and clean coal handling

- Tailings and refuse thickening operations

- Coal preparation plant closed-water circuits

- Advanced coal cleaning and beneficiation systems

- Tailings Management Systems:

- High-density and paste tailings systems

- Large-capacity thickener operations

- Filtered tailings and dry stack systems

- Water recovery and recycling operations

- Environmental monitoring and compliance systems

Chemical & Petrochemical Complexes

- Large-Scale Process Operations:

- Reactor effluent and product separation systems

- Catalyst slurry circulation and regeneration

- Large-capacity crystallization and precipitation

- Solvent extraction and purification processes

- Polymer and specialty chemical manufacturing

- Integrated Waste Management:

- Chemical waste treatment and neutralization

- Hazardous material processing and disposal

- Incineration and thermal oxidation systems

- Scrubber and emission control systems

- Residue handling and ultimate disposal

Power Generation & Energy Infrastructure

- Fossil Fuel Power Plants:

- Coal handling and preparation systems

- Ash handling and disposal operations

- Flue gas desulfurization (FGD) systems

- Cooling tower and water treatment systems

- Waste heat recovery and cogeneration

- Renewable Energy Systems:

- Large-scale biomass handling and processing

- Biogas upgrading and purification systems

- Geothermal brine and steam handling

- Concentrated solar power (CSP) heat transfer systems

- Energy storage system fluid handling

International Standards & Advanced Certifications

Global Design Standard Compliance

- API Standards Portfolio: API 6A (wellhead), API 6D (pipeline), API 598 (testing)

- ASME Code Compliance: B16.34 (valve design), B31.1/3/4/8 (piping systems)

- European Harmonized Standards: EN 19434 (industrial valves), EN 12266 (testing)

- ISO International Standards: ISO 14313 (pipeline valves), ISO 5208 (testing)

- Industry-Specific Standards: AWWA C500/C504 (gate valves), MSS SP-81 (knife gates)

- Military/Aerospace Standards: MIL-STD, AS, QQ specifications where applicable

Advanced Testing & Validation Protocols

- Comprehensive Pressure Testing: API 598, ISO 5208, EN 12266, ASME B16.34

- Extended Leakage Classifications: API 598 Class I-VI, ISO 5208 Rate A-GG

- Fire Safety & Emergency Response: API 607, ISO 10497, BS 6755, UL listings

- Fugitive Emissions Certification: ISO 15848, API 622/624, TA-Luft, EPA regulations

- Functional & Endurance Testing: MSS SP-81, AWWA C500, custom life-cycle testing

- Environmental Testing: Salt spray, UV exposure, thermal cycling, vibration

Premium Quality Management Systems

- Aerospace Quality: AS9100 Rev D with NADCAP special processes

- Nuclear Quality: ASME NQA-1, 10CFR50 Appendix B, CSA N285.0

- Medical Device Quality: ISO 13485 for pharmaceutical and biotech applications

- Automotive Quality: IATF 16949 for precision manufacturing processes

- Energy Sector Quality: ISO 29001 for petroleum and natural gas industries

- Environmental Management: ISO 14001 with carbon neutrality initiatives

Specialized Product Certifications

- Pressure Equipment Directive: CE marking per 2014/68/EU with Module H

- ATEX Explosive Atmospheres: 2014/34/EU Zone 0/1/2 equipment certification

- IECEx International: Global explosive atmosphere certification scheme

- Marine Classification Society: ABS, DNV-GL, Lloyd’s Register, BV approvals

- Nuclear Regulatory: ASME N-stamp, Canadian Nuclear Safety Commission

- Seismic Qualification: IEEE 344, IBC, UBC seismic analysis and testing

State-of-the-Art Automation Systems

Advanced Pneumatic Technologies

- Ultra-High Performance Actuators:

- Output torques from 10,000 to 100,000 Nm available

- Operating pressure ranges: 2-16 bar (30-232 PSI)

- Response times: 2-10 seconds with variable speed control

- Fail-safe configurations with emergency accumulator systems

- Marine-grade corrosion protection and weatherproof construction

- Intelligent Pneumatic Control:

- Digital pneumatic positioners with 0.1% positioning accuracy

- Advanced diagnostics with valve signature analysis

- Predictive maintenance algorithms and trending capabilities

- Multi-protocol communication: HART, Foundation Fieldbus, Profibus PA

- Cybersecurity features per IEC 62443 industrial security standards

- Integrated Pneumatic Systems:

- Custom-engineered actuator packages with local controls

- Instrument air treatment and emergency backup systems

- Solenoid valve manifolds with diagnostic capabilities

- Pneumatic partial stroke testing (PST) for safety systems

- Explosion-proof certification for hazardous area service

Next-Generation Electric Actuation

- High-Torque Multi-Turn Systems:

- Output torques from 5,000 to 200,000 Nm capability

- Voltage options: 100-690V AC, 24-250V DC, universal input

- Precision gearing with anti-backlash and self-locking features

- Manual override with declutching and position indication

- Motor protection: thermal, current, voltage, phase monitoring

- Smart Electric Actuation Technology:

- Variable frequency drives (VFD) for precise speed control

- Absolute encoder position feedback with 0.1° resolution

- Advanced motor control algorithms for optimal performance

- Integrated safety functions: SIL 2/3, proof testing, diagnostics

- Edge computing for local control and decision-making

- Industrial IoT Integration:

- 5G/LTE cellular communication for remote locations

- WiFi 6 and industrial Ethernet connectivity options

- Cloud-based analytics and machine learning capabilities

- Digital twin synchronization and virtual commissioning

- Blockchain-based security and operational records

Hydraulic & Electrohydraulic Excellence

- Ultra-High Force Hydraulic Systems:

- Force capabilities exceeding 1,000,000 N (225,000 lbf)

- Operating pressures up to 700 bar (10,000 PSI)

- Custom cylinder designs with integrated position feedback

- Advanced cushioning and flow control for smooth operation

- Fire-resistant hydraulic fluids and explosion-proof components

- Precision Electrohydraulic Control:

- Servo valve positioning with 0.05% accuracy capability

- Integrated hydraulic power units with variable displacement pumps

- Advanced filtration systems with condition monitoring

- Emergency accumulator systems for fail-safe operation

- Remote control with fiber optic communication links

Innovation Leadership: Visit our Center of Excellence for DN300 valve technology to experience the future of industrial valve systems and participate in cutting-edge development programs.

Global Partnership: Join our worldwide network of certified partners, distributors, and service providers to deliver world-class valve solutions to your customers and markets.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.