Electric Knife Gate Valve

When your application demands precise automated control with intelligent feedback and remote monitoring capabilities, an electric knife gate valve delivers exceptional performance and advanced process integration. This sophisticated electric knife gate valve is engineered for applications requiring precise positioning control — whether you’re managing automated treatment plants, intelligent process systems, or critical infrastructure where advanced control and diagnostics are essential. The high-performance electric actuator ensures accurate positioning and consistent torque control, while maintaining the superior cutting action of our proven knife gate design. With intelligent control systems and comprehensive feedback capabilities, it provides advanced automated service in demanding industrial environments where precision and reliability are paramount.

Ready to achieve intelligent automation in your advanced process applications? Contact us today for an electric solution engineered for your specific control requirements. Let TOT Valve digitize your operations with proven electric precision.

The TOT Valve You Can Depend On – Electric Precision When Intelligence Meets Performance

When your process requires precise positioning, advanced diagnostics, or seamless integration with digital control systems, you need the superior intelligence of our electric knife gate valve. With precision electric actuators and smart control technology, this knife gate valve provides accurate positioning, comprehensive diagnostics, and exceptional reliability — all while maintaining the reliable cutting action that makes knife gates ideal for challenging media.

The electric operation design provides precise control and real-time feedback throughout the valve’s service life, making it the preferred choice for intelligent automation and Industry 4.0 applications.

Why Electric Knife Gate Valve Works for You?

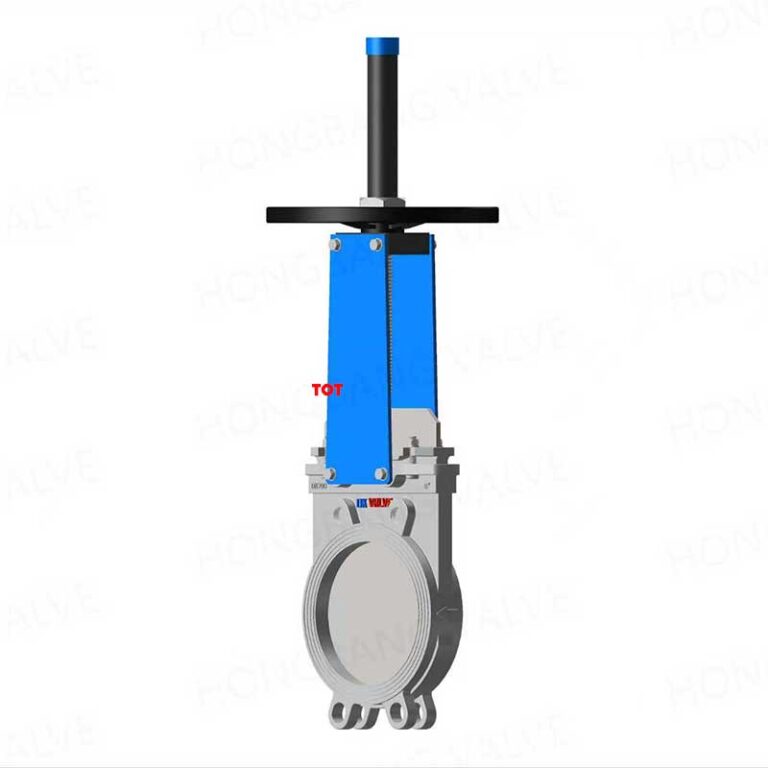

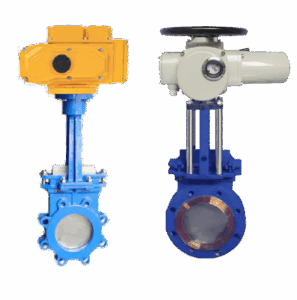

electric knife gate valve features

- Precision electric actuator provides accurate positioning with 0.1% repeatability

- Variable speed control allows optimized opening/closing rates for process requirements

- Intelligent diagnostics monitor actuator performance and predict maintenance needs

- Multi-turn capability enables precise throttling and modulating control

- Torque monitoring prevents valve damage and indicates process conditions

- Corrosion-resistant construction ensures long-term reliability in harsh environments

- Knife-edge gate cuts through fibrous materials, settled solids, and viscous media efficiently

- Digital communication supports HART, Modbus, Profibus, and Ethernet protocols

- Position feedback provides real-time valve position with 0.1° accuracy

- Self-diagnostics continuously monitor actuator health and performance parameters

- Emergency manual override maintains operation capability during power outages

Electric Knife Gate Valve Main Technical Specifications & Performance

Intelligent Automation, Precision Electric Control, Knife Gate Valve

| Specification | Details |

|---|---|

| Design & Manufacturing Standard | MSS SP-81, AWWA C515, IEC 60034 |

| Size Range | DN50 to DN1200 mm; NPS 2″-48″ (Customized to Your Request) |

| Pressure Ratings | PN6, PN10, PN16, PN25, ANSI 150-300Psi, 5K/10K, etc. |

| Working Pressure Classification | DN50–DN300: 16Bar; DN350–DN500: 10Bar; DN600–DN800: 6Bar; DN900–DN1200: 4Bar |

| Operating Speed | 30-300 seconds full stroke (variable and programmable) |

| Power Supply | 110VAC, 220VAC, 380VAC, 24VDC (50/60Hz) |

| Face-to-Face Standard | MSS SP-81, AWWA C515 |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Testing Standard | MSS SP-81, API 598, EN 12266-1, IEC 60534 |

| Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature Range | -40°C to +150°C (standard), up to +200°C with high-temp motors |

| Motor Protection | IP67, IP68, NEMA 4X, Explosion-proof (ATEX, FM, CSA) |

| Control Standards | IEC 60534, ISA-75, NEMA, IEC 61508 (SIL) |

| Applications | Process Automation, Water Treatment, Power Plants, Chemical Processing, Smart Manufacturing |

| Control Modes | On/Off, Modulating, Emergency Shut-off, Positioning Control |

electric knife gate valve components

Electric Knife Gate Valve Main Components and Materials

| Part Name | Material Options | ||

|---|---|---|---|

| WCB | CF8 | CF8M | |

| Valve Body | WCB | CF8 | CF8M |

| Gate | 304SS | 316SS | 316L |

| Seat | EPDM/Metal | EPDM/Metal | EPDM/Metal |

| Electric Motor | Aluminum | Aluminum | 316SS |

| Gear Box | Cast Iron | Aluminum | 316SS |

| Motor Housing | Aluminum | Aluminum | 316SS |

| Control Unit | Aluminum | Aluminum | 316SS |

| Stem | 2Cr13 | 316SS | 316L |

| Stem Coupling | 304SS | 316SS | 316L |

| Position Sensor | Aluminum | Aluminum | 316SS |

| Limit Switches | Aluminum | Aluminum | 316SS |

| Wiring Harness | PVC/PTFE | PVC/PTFE | PTFE |

| Junction Box | Aluminum | Aluminum | 316SS |

| Manual Override | Steel | 304SS | 316SS |

| Mounting Bracket | Carbon Steel | 304SS | 316SS |

| Fasteners | A193-B7 | A4-70 | A4-80 |

Advanced Electric Actuation Technology

Precision Motor Control: Servo-quality motors with encoder feedback for accurate positioning

Variable Speed Drive: Electronic speed control optimizes cycle times for process requirements

Torque Limiting: Electronic torque monitoring prevents valve damage and indicates blockages

Self-Diagnostics: Continuous monitoring of motor current, temperature, and vibration

Digital Communication: Native support for industrial communication protocols

Backup Power: Optional battery backup for emergency operation during power outages

TOT Valve Tailored for Your Electric Automation Applications – Smart Control Systems

You can customize this electric knife gate valve for your exact automation requirements:

Motor Options:

- Standard AC Motors: 110-380VAC, 50/60Hz for general automation applications

- Servo Motors: High-precision positioning with encoder feedback

- DC Motors: 24VDC operation for low-voltage control systems

- Explosion-Proof Motors: ATEX, FM, CSA certified for hazardous areas

Control Systems:

- Basic On/Off: Simple open/close control with limit switch feedback

- Positioning Control: Precise valve positioning with 4-20mA or digital control

- Modulating Service: Continuous throttling control for flow regulation

- Safety Shut-off: Fast-acting emergency closure with SIL certification

Communication Options:

- Analog Signals: 4-20mA, 0-10V position and diagnostic feedback

- Digital Protocols: HART, Modbus RTU/TCP, Profibus DP, Foundation Fieldbus

- Industrial Ethernet: EtherNet/IP, Profinet, EtherCAT for real-time control

- Wireless: WirelessHART for remote monitoring applications

electric knife gate valve performance

Electric Performance & Control Data

| Valve Size | Motor Power | Operating Time | Position Accuracy | Max Torque (Nm) | Power Consumption |

|---|---|---|---|---|---|

| DN50-80 | 0.25-0.5 kW | 30-60 sec | ±0.1% | 500-1000 | 2-4A |

| DN100-150 | 0.5-1.0 kW | 45-90 sec | ±0.1% | 1000-2000 | 4-8A |

| DN200-300 | 1.0-2.0 kW | 60-120 sec | ±0.1% | 2000-4000 | 8-15A |

| DN350-400 | 2.0-3.0 kW | 90-180 sec | ±0.2% | 4000-8000 | 15-25A |

| DN450-600 | 3.0-5.0 kW | 120-300 sec | ±0.2% | 8000-15000 | 25-40A |

Digital Integration & Industry 4.0 Ready

Smart Valve Technology: Built-in intelligence provides predictive maintenance capabilities

Cloud Connectivity: Optional IoT gateways for remote monitoring and control

Data Analytics: Performance trending and optimization recommendations

Cybersecurity: Industrial-grade security protocols and encrypted communications

Asset Management: Integration with plant asset management systems

Remote Diagnostics: Expert support through secure remote access capabilities

Performance Advantages & Testing

Precise Positioning: Electronic control provides repeatable and accurate valve positioning

Diagnostic Intelligence: Continuous monitoring identifies potential issues before failure

Energy Efficiency: Variable speed control minimizes power consumption

Process Optimization: Real-time feedback enables closed-loop process control

Reduced Downtime: Predictive maintenance prevents unexpected failures

Remote Monitoring: 24/7 surveillance capability from control rooms or mobile devices

Quality Assurance & Certification

Every TOT electric knife gate valve undergoes rigorous testing:

- Hydrostatic pressure testing at 1.5x working pressure

- Electric performance testing including speed, torque, and positioning accuracy

- Endurance testing for motor and gear box durability

- Environmental testing for temperature, humidity, and vibration resistance

- EMC testing for electromagnetic compatibility in industrial environments

- Safety certification including functional safety (SIL) where required

Installation & Commissioning Benefits

Plug-and-Play Installation: Pre-configured and tested actuator/valve assemblies

Flexible Power Options: Multiple voltage and frequency options available

Simple Wiring: Standard industrial connectors and comprehensive wiring diagrams

Auto-Commissioning: Self-setup routines for rapid system integration

Configuration Tools: PC-based software for setup and diagnostics

Training Programs: Comprehensive operator and maintenance training available

Advanced Control Features

Adaptive Control: Learning algorithms optimize operation for specific applications

Load Monitoring: Real-time torque feedback indicates process conditions

Fault Detection: Comprehensive alarm and diagnostic capabilities

Remote Updates: Firmware updates via network connection

Historical Data: Performance logging and trend analysis capabilities

Integration Ready: Native support for major DCS and SCADA platforms

Environmental & Safety Compliance

Hazardous Area Certification: ATEX, IECEx, FM, CSA approvals available

Functional Safety: SIL 2/3 certified designs for safety instrumented systems

Environmental Protection: IP67/IP68 ratings for harsh industrial environments

EMC Compliance: Meets industrial electromagnetic compatibility standards

Energy Efficiency: NEMA Premium efficiency motors available

Quality Standards: ISO 9001 certified manufacturing and IEC 61508 functional safety

Contact TOT Valve today for technical consultation and competitive quotation on your electric knife gate valve requirements for intelligent automation applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.