Hydraulic Knife Gate Valve

When your application demands maximum power and reliable operation under extreme conditions, a hydraulic knife gate valve delivers unmatched force and performance in heavy-duty applications. This powerful hydraulic knife gate valve is engineered for applications requiring exceptional torque output — whether you’re controlling large-diameter pipelines, high-pressure systems, or extreme service conditions where pneumatic and electric actuators cannot provide sufficient force. The high-force hydraulic actuator ensures reliable operation even under maximum differential pressures, while maintaining the superior cutting action of our proven knife gate design. With fail-safe hydraulic control and robust construction, it provides dependable high-power service in demanding industrial environments where maximum force and reliability are essential.

Ready to achieve maximum power control in your heavy-duty applications? Contact us today for a hydraulic solution engineered for your specific high-force requirements. Let TOT Valve power your operations with proven hydraulic strength.

The TOT Valve You Can Depend On – Hydraulic Power When Maximum Force Meets Reliability

When your process requires extreme actuating force, operates under high differential pressures, or demands reliable performance in remote locations, you need the superior power of our hydraulic knife gate valve. With high-pressure hydraulic systems, this knife gate valve provides maximum torque output, consistent operation under load, and exceptional reliability — all while maintaining the reliable cutting action that makes knife gates ideal for challenging media.

The hydraulic operation design provides maximum force capability and dependable performance throughout the valve’s service life, making it the preferred choice for heavy-duty applications and extreme service conditions.

Why Hydraulic Knife Gate Valve Works for You?

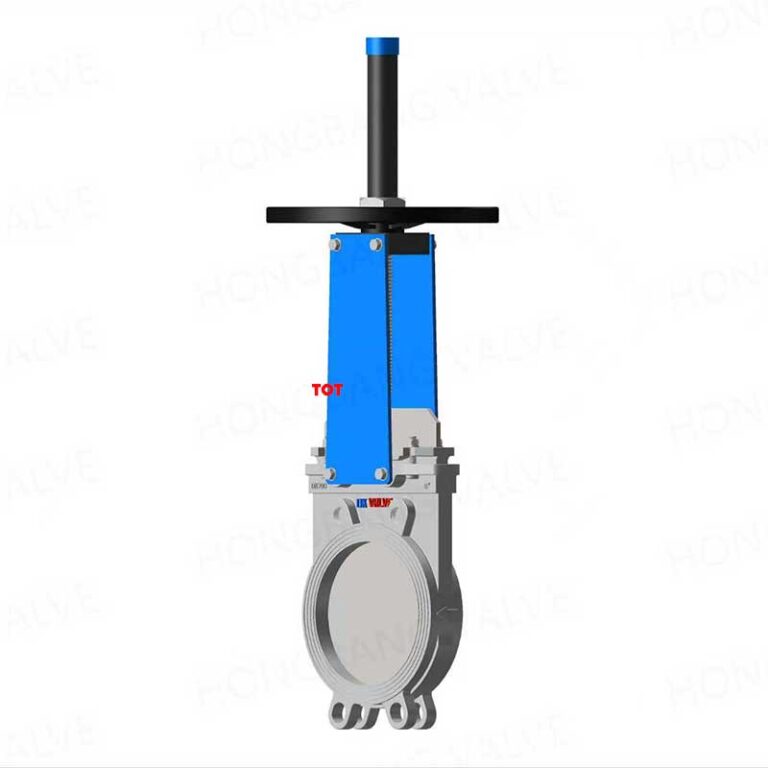

hydraulic knife gate valve features

- High-force hydraulic actuator delivers maximum torque output up to 50,000 Nm

- Consistent operation maintains full force capability regardless of differential pressure

- Fail-safe operation with accumulator backup or spring return configurations

- Remote operation enables control from distances up to 1000 meters

- Variable speed control allows optimized cycle times from 10 seconds to 10 minutes

- Corrosion-resistant construction with stainless steel hydraulic components

- Knife-edge gate cuts through fibrous materials, settled solids, and viscous media efficiently

- High-pressure capability operates reliably with hydraulic pressures up to 210 Bar

- Temperature independence maintains consistent force in extreme temperature conditions

- Explosion-proof designs available for hazardous area installations

- Emergency manual backup provides operation capability during hydraulic system failure

Hydraulic Knife Gate Valve Main Technical Specifications & Performance

Maximum Power Output, High-Pressure Hydraulic Technology, Knife Gate Valve

| Specification | Details |

|---|---|

| Design & Manufacturing Standard | MSS SP-81, AWWA C515, ISO 4413 |

| Size Range | DN50 to DN2000 mm; NPS 2″-80″ (Customized to Your Request) |

| Pressure Ratings | PN6, PN10, PN16, PN25, ANSI 150-600Psi, 5K/10K, etc. |

| Working Pressure Classification | DN50–DN300: 25Bar; DN350–DN500: 16Bar; DN600–DN1200: 10Bar; DN1400–DN2000: 6Bar |

| Operating Speed | 10 seconds to 10 minutes full stroke (programmable) |

| Hydraulic Pressure | 70-210 Bar (1000-3000 PSI) operating pressure |

| Face-to-Face Standard | MSS SP-81, AWWA C515 |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Testing Standard | MSS SP-81, API 598, EN 12266-1, ISO 4413 |

| Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L, Super Duplex |

| Temperature Range | -40°C to +150°C (standard), up to +200°C with high-temp fluids |

| Hydraulic Fluids | Mineral Oil, Synthetic Fluids, Fire-Resistant Fluids (HFC, HFD) |

| Control Standards | ISO 4413, NFPA, IEC 61508 (SIL) |

| Applications | Mining, Steel Mills, Power Generation, Large Pipelines, Offshore, Heavy Industry |

| Control Modes | On/Off, Proportional, Emergency Shut-off, Load Sensing |

hydraulic knife gate valve components

Hydraulic Knife Gate Valve Main Components and Materials

| Part Name | Material Options | ||

|---|---|---|---|

| WCB | CF8 | CF8M | |

| Valve Body | WCB | CF8 | CF8M |

| Gate | 304SS | 316SS | 316L/Duplex |

| Seat | EPDM/Metal | EPDM/Metal | EPDM/Metal |

| Hydraulic Cylinder | Steel | 316SS | 316SS |

| Piston | Steel | 316SS | 316SS |

| Cylinder Rod | Chrome Plated | 316SS | 316L |

| Rod Seals | NBR/PU | FKM | FKM/PTFE |

| Cylinder Seals | NBR | FKM | FKM |

| Stem | 2Cr13 | 316SS | 316L |

| Stem Coupling | 304SS | 316SS | 316L |

| Hydraulic Manifold | Steel | 316SS | 316SS |

| Control Valve | Steel | 316SS | 316SS |

| Accumulator | Steel | 316SS | 316SS |

| Pressure Sensors | 316SS | 316SS | 316SS |

| Hydraulic Fittings | Steel | 316SS | 316SS |

| Manual Override | Steel | 304SS | 316SS |

Advanced Hydraulic Technology

High-Pressure Systems: Operating pressures up to 210 Bar provide maximum force capability

Load Sensing Control: Automatically adjusts hydraulic pressure to match valve load requirements

Accumulator Systems: Energy storage provides rapid response and emergency operation capability

Proportional Control: Variable flow control enables precise speed and position control

Pressure Compensation: Maintains consistent operation regardless of supply pressure variations

Fire-Resistant Fluids: Compatible with various hydraulic fluids including fire-resistant types

TOT Valve Tailored for Your High-Force Applications – Maximum Power Solutions

You can customize this hydraulic knife gate valve for your exact power requirements:

Actuator Configurations:

- Single Acting: Spring return with hydraulic opening for fail-safe close operation

- Double Acting: Maximum force in both directions for high differential pressure

- Telescopic: Compact design for space-limited installations

- Rotary Vane: Alternative design for specific mounting requirements

Hydraulic Systems:

- Centralized HPU: Multiple valves operated from single hydraulic power unit

- Local Power Pack: Dedicated hydraulic system for individual valve control

- Accumulator Systems: Energy storage for rapid operation and emergency backup

- Manual Pump Backup: Hand pump operation for emergency situations

Control Options:

- Manual Control: Hand-operated directional control valves

- Solenoid Control: Electric pilot valves for remote operation

- Proportional Control: Electronic control for precise positioning

- Servo Control: High-precision feedback control systems

hydraulic knife gate valve performance

Hydraulic Force & Performance Data

| Valve Size | Cylinder Bore | Operating Force | Cycle Time | Hydraulic Flow | Power Required |

|---|---|---|---|---|---|

| DN50-100 | 63-80mm | 20-50 kN | 10-30 sec | 10-20 L/min | 5-10 kW |

| DN125-200 | 100-125mm | 50-120 kN | 15-45 sec | 20-40 L/min | 10-20 kW |

| DN250-400 | 160-200mm | 120-300 kN | 30-90 sec | 40-80 L/min | 20-40 kW |

| DN450-600 | 250-320mm | 300-600 kN | 60-180 sec | 80-150 L/min | 40-75 kW |

| DN700-1000 | 400-500mm | 600-1200 kN | 120-360 sec | 150-300 L/min | 75-150 kW |

| DN1200-2000 | 630-800mm | 1200-3000 kN | 180-600 sec | 300-600 L/min | 150-300 kW |

Hydraulic System Design & Components

Power Unit Selection: Customized HPU design based on valve requirements and duty cycle

Filtration Systems: High-efficiency filtration maintains hydraulic fluid cleanliness

Temperature Control: Cooling systems prevent overheating during continuous operation

Pressure Regulation: Precision pressure control for consistent valve operation

Safety Systems: Relief valves, burst discs, and emergency shutdown capabilities

Monitoring Systems: Pressure, temperature, and flow monitoring with alarm capability

Performance Advantages & Testing

Maximum Force Output: Unmatched actuating force for large valves and high differential pressures

Consistent Performance: Hydraulic power maintains force regardless of valve position

Remote Operation: Safe operation from control rooms in hazardous environments

Emergency Capability: Rapid closure for emergency isolation applications

Heavy-Duty Service: Designed for continuous operation in demanding applications

Extreme Environment: Reliable operation in temperatures from -40°C to +150°C

Quality Assurance & Certification

Every TOT hydraulic knife gate valve undergoes rigorous testing:

- Hydrostatic pressure testing at 1.5x working pressure

- Hydraulic performance testing including force, speed, and positioning verification

- Endurance testing for cylinder and seal durability

- System integration testing with complete hydraulic power unit

- Environmental testing for extreme temperature and pressure conditions

- Safety system testing including emergency shutdown and fail-safe operation

Installation & System Integration

Complete System Supply: Valve, actuator, and hydraulic power unit as integrated package

Flexible Installation: Multiple mounting orientations and remote hydraulic connections

System Design Support: Complete hydraulic system engineering and optimization

Commissioning Services: Expert startup, testing, and operator training

Documentation Package: Comprehensive system manuals, P&IDs, and maintenance procedures

Global Support: Worldwide service network for system maintenance and support

Safety & Environmental Features

Fail-Safe Design: Multiple fail-safe options including spring return and accumulator backup

Environmental Protection: Biodegradable hydraulic fluids available for sensitive environments

Leak Detection: Monitoring systems detect and alarm hydraulic fluid leaks

Fire Safety: Fire-resistant hydraulic fluids for high-risk applications

Pressure Safety: Comprehensive safety systems prevent overpressure conditions

Emergency Systems: Manual backup operation and rapid emergency shutdown capability

Cost Benefits & Lifecycle Value

Maximum Power Efficiency: Highest force-to-cost ratio for large valve applications

Extended Service Life: Robust hydraulic components designed for 20+ year service

Energy Efficiency: On-demand operation reduces energy consumption compared to continuous systems

Reduced Infrastructure: No electrical power required at valve location

Proven Technology: Mature hydraulic technology with established maintenance practices

Total Cost Optimization: Lowest lifecycle cost for high-force applications

Contact TOT Valve today for technical consultation and competitive quotation on your hydraulic knife gate valve requirements for maximum power applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.