Pneumatic Ceramic Ball Valve

TOT Valve Pneumatic ceramic ball valve is a control valve designed for high wear and high corrosion conditions, because we use high-quality alumina ceramic (Al₂O₃) or zirconium oxide ceramic (ZrO₂) as the material of the ball and valve seat.

If you are applied to the conveying system of high-hardness particles and highly corrosive media in thermal power plants, mining, metallurgy, chemical industry, coal chemical industry and other industries, then our pneumatic ceramic ball valve will be your ideal choice.

Contact us now to get a competitive quote.

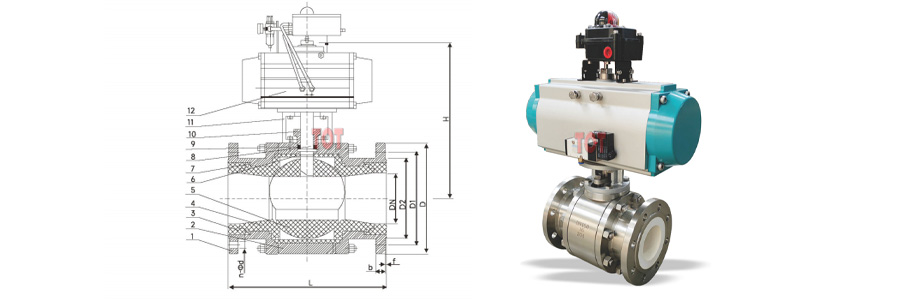

Pneumatic Ceramic Ball Valve Structure

Sealing Structure: ceramic to ceramic hard seal

Valve Body Material: carbon steel WCB complies with ASTM A216 standard, CF8/CF8M stainless steel complies with ASTM A351 standard

Ball and Valve Seat Material: Alumina ceramic (Al₂O₃) or zirconium oxide ceramic (ZrO₂) with extremely high hardness and corrosion resistance

Actuator: Matching pneumatic actuator, optional single and double action, fast response speed, can be equipped with solenoid valves, limit switches, positioners and other accessories

Design Standard of Pneumatic Ceramic Ball Valve Implemented by TOT Valve

| Nominal Pressure | Design and Manufacture | Face-to-Face Dimension | Flange Dimension | Inspection and Test | Valve Testing |

|---|---|---|---|---|---|

| PN10/16, ANSI Class 150LB/300LB | GB/T 12224, ASME B16.34 | Manufacturers Standard, ASME B16.5 & B16.47 | JB/T 79.1, ANSI B16.5, DIN 2543, JIS B2020 | GB/T 9092, ASME B16.34 | API 598 |

Pneumatic Ceramic Ball Valve Performance Advantages

Extremely Strong Wear Resistance: high ceramic hardness (Vickers hardness up to HRA 88 or above), greatly extending the service life

Strong Corrosion Resistance: suitable for harsh media such as acid, alkali, salt spray, etc.

Quick Opening and Closing: pneumatic operation, suitable for frequent opening and closing conditions

Long Service Life: ceramic internals are 3-5 times longer than ordinary metal valves, or even higher

Wide Application Areas: thermal power plant desulfurization system (lime slurry, gypsum slurry), coal powder conveying system, pneumatic conveying system, high-temperature granular material cutting in the metallurgical industry, chemical corrosive acid and alkali liquid conveying

Main Component Materials

| Number | Name | Material | Number | Name | Material |

|---|---|---|---|---|---|

| 1 | Body | CF8/CF8M/WCB | 7 | Stem | CF8/2Cr13 |

| 2 | Middle Valve Body | CF8/CF8M/WCB | 8 | Packing | Graphite |

| 3 | Flange Seat | Structural Ceramics | 9 | Packing Gland | CF8/CF8M/WCB |

| 4 | Seat | Structural Ceramics | 10 | Bracket | Q235 |

| 5 | Ball | Structural ceramics | 11 | Finished Product | |

| 6 | Middle Sleeve | Structural Ceramics | 12 | Worm Gear | |

Main Appearance and Connection Dimensions (Unit: mm)

| Size | PN | L | D | D1 | D2 | C | H | n-Φd | |

|---|---|---|---|---|---|---|---|---|---|

| DN | In | ||||||||

| 50 | 2″ | 16 | 200 | 160 | 125 | 100 | 16 | 190 | 4-18 |

| 65 | 2-1/2″ | 220 | 180 | 145 | 118 | 18 | 220 | 4-18 | |

| 80 | 3″ | 250 | 195 | 160 | 135 | 20 | 235 | 8-18 | |

| 100 | 4″ | 280 | 215 | 180 | 155 | 20 | 255 | 8-18 | |

| 125 | 5″ | 320 | 245 | 210 | 185 | 22 | 260 | 8-18 | |

| 150 | 6″ | 360 | 280 | 240 | 210 | 24 | 310 | 8-23 | |

| 200 | 8″ | 400 | 335 | 295 | 265 | 24 | 365 | 12-23 | |

| 250 | 10″ | 533 | 405 | 355 | 320 | 26 | 430 | 12-25 | |

| 300 | 12″ | 610 | 455 | 410 | 475 | 30 | 460 | 12-25 | |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.