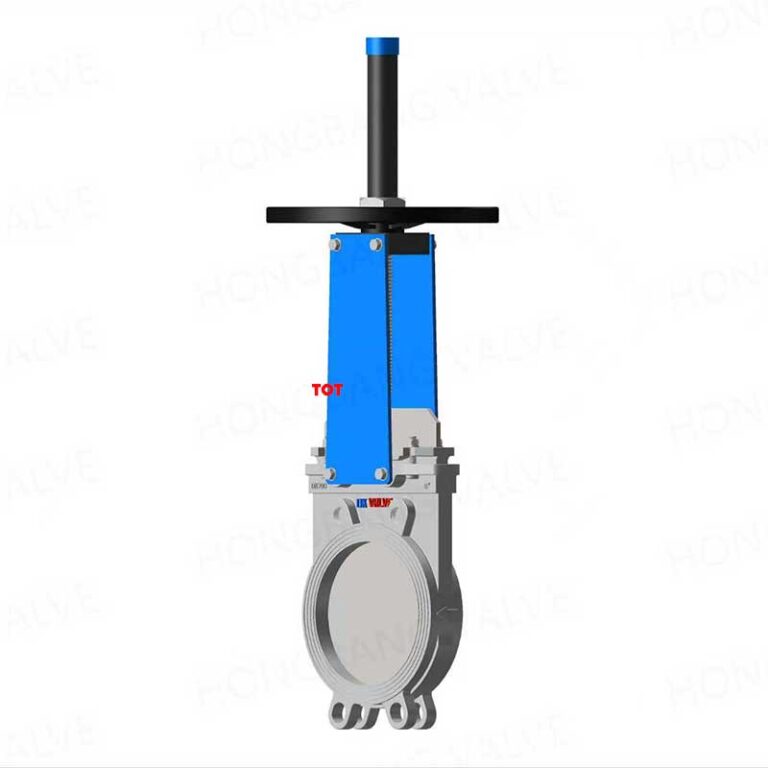

Wafer Type Knife Gate Valve

When you need space-saving isolation in tight pipeline configurations, a wafer type knife gate valve is your ideal solution. This lightweight, compact stainless steel wafer knife gate valve is engineered for installations where space is premium and weight reduction is critical — perfect for handling slurry, pulp, corrosive fluids, and abrasive media. The wafer design fits between existing flanges without additional bolting, significantly reducing installation costs and system footprint. With corrosion-resistant stainless steel construction and versatile actuation options, it delivers reliable performance in industries demanding efficiency, compact design, and cost-effective solutions.

Ready to optimize your flow control system? Contact us today for a customized wafer valve solution tailored to your exact specifications. Let TOT Valve streamline your operations.

The TOT Valve You Can Depend On – Compact Design, Maximum Performance

When your process involves slurry, pulp, abrasive fluids, or corrosive chemicals in space-constrained installations, you need the reliability of our wafer type knife gate valve. With its lightweight wafer body design, this knife gate valve provides absolute shut-off performance, bi-directional sealing capability, and easy installation between existing flanges — all while maintaining the rugged performance you expect.

The wafer design eliminates the need for through-bolts, allowing installation directly between pipeline flanges using existing bolting, making it the most economical choice for new installations and retrofits.

Why Wafer Type Knife Gate Valve Works for You?

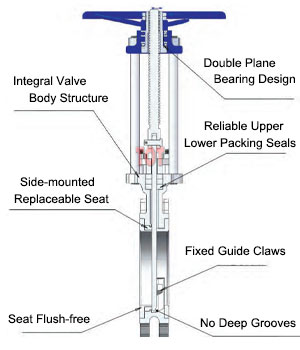

- Corrosion-resistant stainless steel (SS304/316) keeps your operation running in aggressive environments.

- Wafer-style design fits between flanges with no additional bolting required, reducing installation costs.

- Knife-edge gate slices through thick media like pulp, slurry, or powders with no clogging.

- Bi-directional sealing ensures reliable shut-off regardless of flow direction.

- Soft or metal seats ensure you get the shut-off performance your application demands.

- Choose your actuator – manual, pneumatic, electric, or chainwheel – for total control.

- Lightweight construction reduces pipeline stress and support requirements.

- Low maintenance – reduce downtime with replaceable seats and packing.

- Compact design saves valuable space in crowded installations.

- No flow restriction – full bore design maintains system efficiency.

Wafer Knife Gate Valve Main Technical Specifications & Performance

Bi-directional Sealing, Resilient Seat, Wafer Type Knife Gate Valve

| Specification | Details |

|---|---|

| Design & Manufacturing Standard | MSS SP-81, API 6D |

| Size Range | DN50 to DN1200 mm; NPS 2″-48″ (Customized to Your Request) |

| Pressure Ratings | PN10, PN16, ANSI 150Psi, 5K/10K, etc. |

| Working Pressure Classification | DN50–DN250: 10Bar; DN300–DN450: 7Bar; DN500–DN600: 4Bar; DN700–DN1200: 2Bar |

| Face-to-Face Standard | MSS SP-81, Short Pattern |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Inspection & Testing Standard | MSS SP-81, API 598 |

| Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature–Pressure Rating Standards | GB/T12224–2007, ASME B16.34–2009, ISO7005–1 |

| Applications | Pulp & Paper, Mining, Chemical, Pharmaceutical, Potable Water, Wastewater Treatment, Municipal Sewage, Water Conservancy, Power Plants, etc. |

| Actuation Methods | Manual, Pneumatic, Electric, Gear Drive, Chain Drive, Lever |

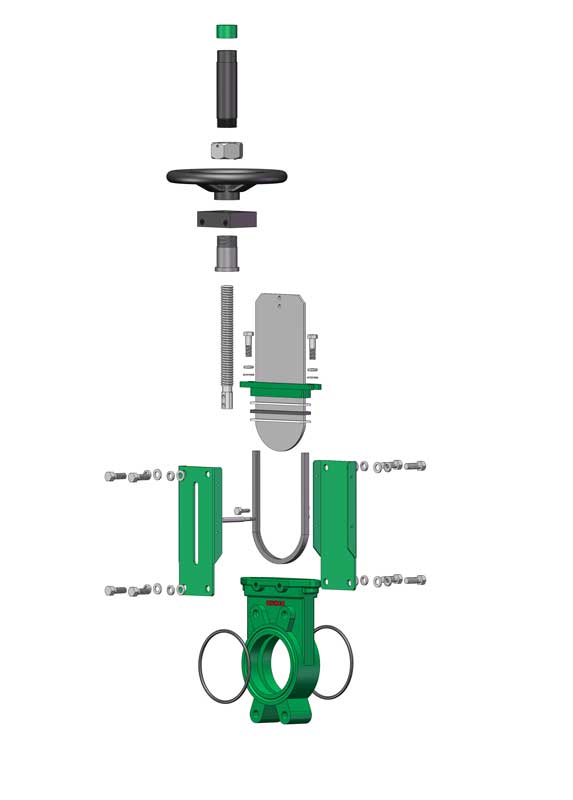

Wafer Knife Gate Valve Main Components and Materials

| Part Name | Material Options | ||

|---|---|---|---|

| WCB | CF8 | CF8M | |

| Body | WCB | CF8 | CF8M |

| Gate | 304 | 316 | 316L |

| Seat | STL or EPDM | STL or EPDM | STL or EPDM |

| O-ring | NBR | NBR | EPDM |

| Gland | WCB | CF8 | CF8M |

| Packing | PTFE | PTFE | PTFE |

| Yoke | Q235 | 304 | 316 |

| Stem | 2Cr13 | 316 | 316L |

| Stem Nut | Brass | Brass | Brass |

| Pin | 65Mn | 304 | 316 |

| Handwheel | GGG30 | GGG30 | GGG30 |

| Stem Protector | 304 | 304 | 316 |

| Fasteners | A2-70 | A4-70 | A4-80 |

TOT Valve Tailored for Your System – Custom Options

You can customize this wafer valve for your exact system requirements:

Gate Finish: Polished, hardened edge, or duplex stainless

Seat Type: EPDM, PTFE, Viton, NBR, or metal seated with Stellite overlay

Actuation Options: Pneumatic actuator with solenoid & limit switch, electric motor with controls

Body Coating: Epoxy, ceramic lining, PFA lining for enhanced chemical resistance

Automation Ready: ISO 5211 mounting pad for easy actuator installation

Special Features: Extended stem for buried service, position indicators, limit switches

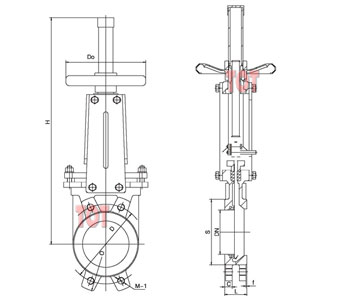

Wafer Knife Gate Valve Dimensions

TOT valve can provide you with various sizes of wafer knife gate valve. We have listed some wafer type knife gate valve sizes for PN16 for your reference.

If you don’t have the wafer type knife gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) |

|---|---|---|---|---|---|---|---|---|

| DN(mm) | NPS(in) | |||||||

| 50 | 2″ | 43 | 135 | 106 | 100 | 129 | 85 | 180 |

| 65 | 2-1/2″ | 46 | 155 | 106 | 115 | 147 | 85 | 180 |

| 80 | 3″ | 46 | 175 | 106 | 121 | 168 | 85 | 200 |

| 100 | 4″ | 52 | 163 | 106 | 138 | 192 | 85 | 200 |

| 125 | 5″ | 56 | 192 | 120 | 160 | 215 | 87 | 250 |

| 150 | 6″ | 61 | 216 | 130 | 185 | 245 | 87 | 280 |

| 200 | 8″ | 78 | 271 | 130 | 235 | 302 | 105 | 300 |

| 250 | 10″ | 92 | 335 | 140 | 300 | 355 | 105 | 350 |

| 300 | 12″ | 102 | 381 | 160 | 350 | 401 | 105 | 400 |

| 350 | 14″ | 114 | 436 | 180 | 400 | 465 | 117 | 450 |

| 400 | 16″ | 127 | 505 | 180 | 455 | 511 | 117 | 450 |

Installation Advantages

Cost Effective: No additional through-bolts required — uses existing flange bolting

Space Saving: Minimal face-to-face dimension reduces pipeline length

Weight Reduction: Lighter than lug-type valves, reducing support requirements

Easy Retrofit: Perfect replacement for existing wafer valves without pipeline modification

Maintenance Friendly: Can be removed for service without disturbing adjacent piping

Quality Assurance & Standards Compliance

Every TOT wafer knife gate valve undergoes rigorous factory testing including:

- Hydrostatic shell testing at 1.5x working pressure

- Seat leakage testing per MSS SP-81 standards

- Operational torque verification

- Material certification and traceability

- Dimensional inspection per drawing specifications

Contact TOT Valve today for technical consultation and competitive quotation on your wafer knife gate valve requirements.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.